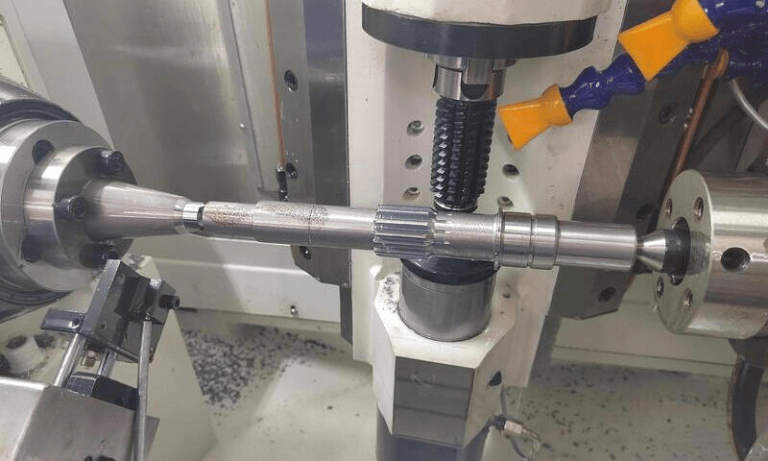

Complex and strong splined shafts play a key role in modern machinery, ensuring smooth power transmission and rotational precision. Whether you are an engineer, manufacturer, or someone interested in these mechanical marvels, you need to have a thorough understanding of the intricacies of splined shafts, their benefits, the know-how behind them, and their countless applications to get the most out of them . them.

1What is a splined shaft?

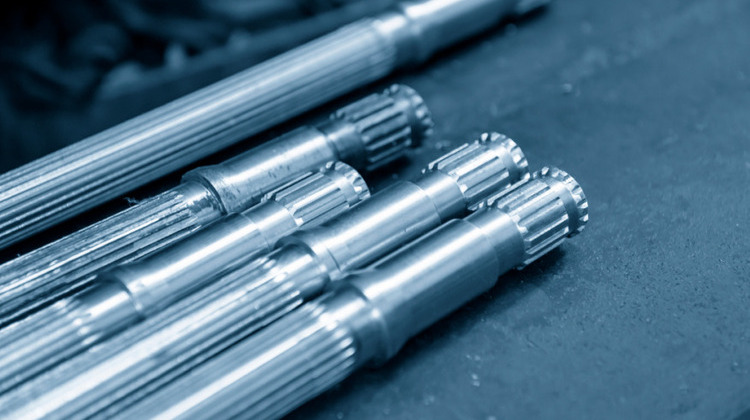

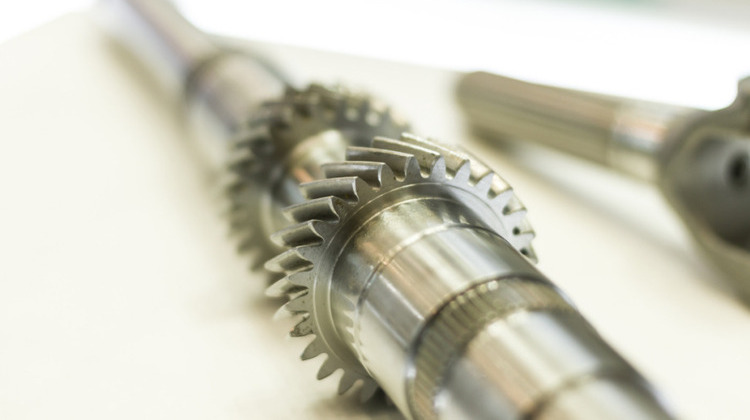

Splined shafts are specialized mechanical components essential for various mechanical and automotive systems. These shafts are characterized by their unique ridges (called splines) and can have internal or external splines.

Their design allows them to seamlessly engage with the corresponding grooves of the mating parts, ensuring a secure connection. This locking mechanism is essential for efficient torque transmission and precise rotational alignment. Splined shafts improve system performance and durability by preventing slippage and ensuring even load distribution.

Their adaptability and precision make them the first choice for industries that require safe and efficient power transmission.

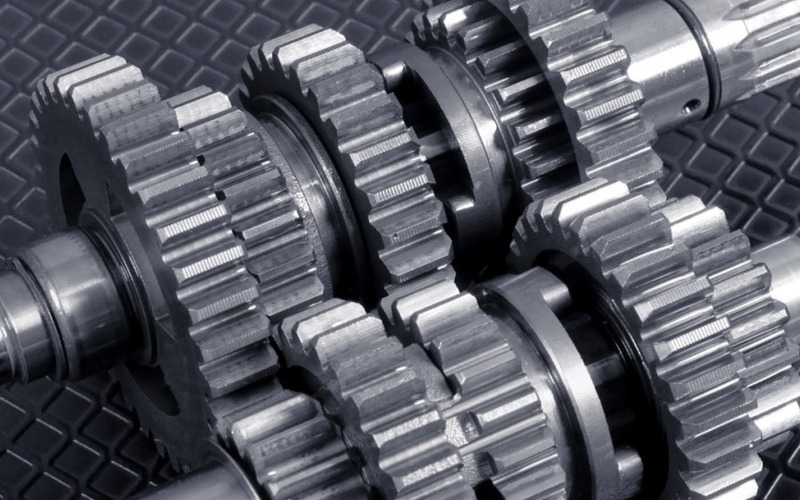

Functions as an anti-rotation device The splined shaft acts as an anti-rotation device, fitting into the grooves of the mating part. This connection ensures torque transfer without misalignment, promoting synchronized operation and optimal system functionality.

Torque Transmission and Angle Matching These shafts play a vital role in transmitting torque and power. Their design ensures precise angular alignment, allowing components to work in harmony, increasing system efficiency and minimizing wear.

2 Advantages of splined shafts over other alternative shafts

Torque transmitting splined shafts can transmit higher torques than ordinary shafts. Interlocking splines provide a larger contact area, ensuring efficient power transfer.

Precisely aligned mesh splines and grooves ensure that the shaft and its mating components maintain precise rotational alignment, reducing the risk of misalignment and subsequent wear.

Anti-rotation feature The splined shaft design prevents unwanted relative rotation between interconnected parts, ensuring synchronized movement and function.

Durability Due to the even distribution of load on the splines, these shafts tend to last longer and are less subject to wear than regular or keyed shafts.

Compact Design Spline connections are generally more compact than other alternatives, allowing for a more elegant mechanical design and efficient use of space.

Reduce Slippage The interlocking nature of the splines ensures minimal slippage, even under high torque conditions, for consistent performance.

Easy assembly and disassembly Spline shafts can be easily connected or disconnected from their corresponding components, making maintenance and replacement of components easier.

3 Main Materials Used in Making Spline Shafts

Stainless Steel and Its Benefits Stainless steel is commonly used in the manufacturing of splined shafts and is known for its corrosion resistance and strength. This material guarantees durability even in harsh environments, making the splined shaft more reliable. Stainless steel’s non-reactivity and excellent wear resistance make it the first choice for durable and efficient splined shafts.

Carbon Steel and Its Unique Properties Carbon steel is the material of choice for manufacturing splined shafts due to its strength and ductility. Its combination of durability and workability makes it an ideal material for complex spline designs. The cost effectiveness and strength of carbon steel make it the first choice for many industrial and automotive applications.

Alloy Steel and Its Functions Chromium and molybdenum are added to alloy steel and are used in splined shaft structures for their enhanced properties. Alloy steel has higher strength and wear resistance and can withstand harsh conditions better than standard steel. The versatility and adaptability of alloy steel makes it the first choice for high-performance splined shafts.

Aluminum Alloys and Their Advantages Aluminum alloys are light but strong and can be used to make splined shafts for applications where weight reduction is required. These alloys offer good corrosion resistance and a high strength-to-weight ratio, ensuring durability without compromising performance. Their malleability allows them to design complex flutes and can therefore be used in a wide range of industries.

Bronze, the other material used in splined shafts, is favored for its wear resistance and is ideal where lubrication is unstable. Meanwhile, brass (a copper-zinc alloy) was chosen as the material for the splined shaft due to its machinability and anti-corrosion properties.

Where corrosion resistance and reduced torque are essential, lightweight materials such as nylon and other plastics are favored, with the added benefit of quiet operation.

Titanium has an excellent strength-to-weight ratio and plays an important role in weight-sensitive industries such as aerospace. Ceramics are suitable for niche applications requiring wear resistance, heat resistance and electrical insulation.

Finally, Teflon-based shafts stand out in scenarios where low friction and low chemical resistance are required.

4Practical applications of splined shafts

01Automotive Industry Description: Spline shafts are an integral part of various automotive systems, ensuring smooth power transmission and precise alignment. Example: In automobiles, splined shafts are often used in the transmission. They connect the transmission to the driveshaft, allowing efficient transfer of power from the engine to the wheels. Steering columns typically use a splined shaft to provide a secure connection between the steering wheel and the steering mechanism. 02Description of the aeronautical industry: In aerospace, splined shafts play a key role in propellers and rotors. Example: In helicopters, the main rotor shaft usually has splines that mesh with corresponding grooves in the rotor hub. This connection ensures that engine power is transmitted efficiently to the rotor blades, allowing for controlled and stable flight. 03Industrial machines Description: Splined shafts are found everywhere in manufacturing units and contribute to the proper functioning of various machines. Example: In conveyor systems, splined shafts connect the motors to the conveyor belts, ensuring synchronized movement. This ensures that items move smoothly through the production line without any hiccups or delays. 04 Agricultural Equipment Description: Agricultural machinery often uses splined shafts to perform power transmission and rotation tasks. Example: Tractors use splined shafts in their power take-off (PTO) systems. PTO shafts transfer power from the tractor to implements such as lawn mowers or combine harvesters, allowing them to operate efficiently. 05 Marine Application Description: In marine environments, splined shafts are used in propulsion systems and other machinery. Example: On boats, the propeller shaft is generally splined at the outlet of the engine. This ensures that the engine’s power is transferred directly to the propeller, propelling the boat forward. 06 Power Tool Description: Many handheld and stationary power tools use splined shafts to transmit torque and connect the tool. Example: Electric drills often have a splined shaft that connects the motor to the chuck. This design ensures that the rotational power of the motor is efficiently transmitted to the drill bit, enabling efficient drilling.

5 Care and maintenance of the splined shaft

01 Cleaning Tips to Extend Life Splined shafts are essential for power transmission in various machines and require regular maintenance to ensure optimal life and performance. Regular inspections can detect signs of wear or damage, paving the way for rapid intervention. Cleaning is crucial, regularly using a soft brush or compressed air to remove dirt and debris. Mild solvents or detergents are effective for deep cleaning, especially when contaminants such as grease and oil have built up. After cleaning, drying is essential to prevent corrosion, and materials prone to rust may benefit from rust inhibitors.

02The Importance and Best Practices of Lubrication Lubrication plays a key role in the maintenance of splined shafts. The choice of lubricant should be consistent with the shaft material and its application. Establishing a consistent lubrication routine minimizes friction and wear, ensuring smooth operation. However, it is essential to ensure that the lubricant is evenly distributed and not over-lubricated, as excessive lubrication can attract dust, leading to potential complications.

Splined shafts have revolutionized power transmission in various industries with their unique design and functionality. Their versatility combined with countless advantages underlines their importance in modern machinery. As you explore the world of splined shafts, remember that quality and precision are crucial.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.