introduce

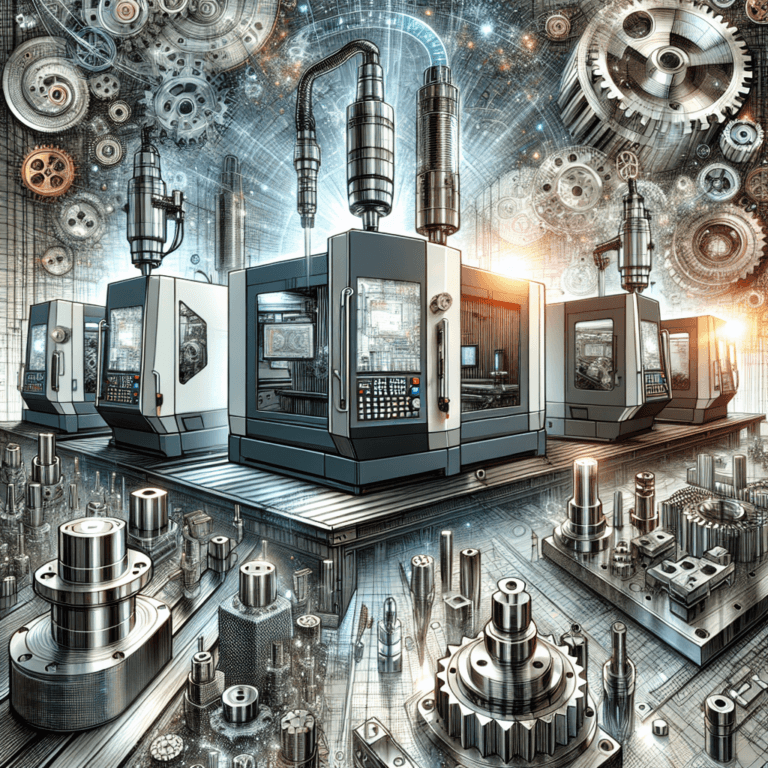

In the rapidly growing field of precision manufacturing, computer numerical control (CNC) technology stands out as the cornerstone of innovation, efficiency and precision. CNC machining centers play a key role in producing complex parts in various industries including aerospace, automotive, medical and electronics. This article explores in depth Top 5 CNC machining centers Revolutionized precision manufacturing. We’ll explore their features, functionality, and applications, showing how they can improve productivity and accuracy in the manufacturing process.

What is CNC machining?

The core of CNC machining is the use of computer control to operate a machine. This includes milling machines, lathes, milling machines and grinders, where precision is critical. CNC technology enables the creation of complex geometries with extremely high precision and repeatability.

How CNC machining works

CNC machining begins with a CAD model (computer-aided design) designed by an engineer or designer. The model is then converted into a format (usually G-code) that the CNC machine can interpret, instructing the machine how to move and operate the tools to create the desired part.

Advantages of CNC machining centers

- accurate: CNC machines can produce parts with tolerances as precise as ±0.001 inches.

- Repeatability: Once programmed, CNC machines can produce the same parts repeatedly without variation.

- flexibility: CNC machining can quickly change production runs to accommodate different designs and applications.

- Increase production speed: CNC machine tools can operate continuously and produce higher output than traditional methods.

Top 5 CNC Machining Centers

Now, let’s dive into the details of the top five CNC machining centers that have set the benchmark in precision manufacturing.

1. Haas VF Series

Overview

Haas Automation has become a leading manufacturer of CNC machine tools. Its VF series of vertical machining centers are known for their superior performance, durability and user-friendly operation.

Main features

- High speed spindle: The VF Series offers spindle speeds up to 24,000 RPM for rapid material removal.

- User friendly controls: These machines feature Haas’ intuitive control interface, making them easy to program and operate.

- solid structure: These machining centers feature a cast iron base design that minimizes vibration, resulting in improved part quality and longer tool life.

Application areas

The VF series is ideal for machining complex parts in the aerospace and automotive industries and is often used in job shops due to its versatility.

2. Reading Genos M560-V

Overview

Okuma’s Genos M560-V vertical machining center combines flexibility with high precision, making it a favorite among manufacturers seeking excellence.

Main features

- Thermal stability: Okuma uses unique thermal management technology to ensure consistent performance even at different temperatures.

- Intelligent control: With built-in conversational programming capabilities, manufacturers can easily set up jobs without extensive programming knowledge.

- Flexible tool options: The M560-V can accommodate multiple tool setups for different applications.

Application areas

This machining center is particularly suitable for industries that require high-precision parts and is often found in medical device manufacturing and precision mold shops.

3. Makino a61nx

Overview

The Makino a61nx is recognized for its strong engineering and high-speed capabilities. It brings advanced technology and efficiency, ensuring excellence in precision manufacturing.

Main features

- Highly rigid shaft design: The a61nx features a rigid shaft configuration that minimizes deflection during machining operations, ensuring optimal accuracy.

- high speed machining: The a61nx is capable of running at high feed rates, which can significantly reduce cycle times.

- Advanced control system: Proprietary Hyper-i control interface provides real-time operating data for enhanced monitoring and control.

Application areas

The a61nx is commonly used in the aerospace industry to machine complex geometries, where accuracy and speed are critical.

4.DMG MORI DMU 50

Overview

The DMG MORI DMU 50 is renowned for its excellent multi-axis functionality. This CNC machining center combines advanced technology with precision engineering to meet the most demanding manufacturing needs.

Main features

- 5-axis machining: The DMU 50 can machine complex parts in virtually any orientation, reducing the need for multiple setups.

- Dynamic Mix Control: This control system provides advanced motion control that translates into superior surface finish and dimensional accuracy.

- User friendly interface: The intuitive operation interface simplifies the programming process, making it easy for even those with limited CNC experience to get started.

Application areas

The machining center is invaluable in industries such as aerospace, medical and automotive where complex designs are the norm.

5.FANUC Robot Drilling Rig

Overview

Fanuc is a global leader in automation and robotics. The Robodrill is designed for high-speed precision machining, making it ideal for efficiency-focused manufacturers.

Main features

- Ultra-fast cycle times: Robodrill features rapid acceleration and deceleration to significantly reduce operating cycle times.

- Compact design: Small footprint enables flexibility in small factory layouts without sacrificing production capacity.

- Integrated automation options: This machine can be easily integrated into automated production lines to improve overall efficiency.

Application areas

Robodrills are often used in high-volume production environments, particularly in electronics manufacturing where speed and precision are critical.

in conclusion

For manufacturers seeking to achieve excellence in precision manufacturing, choosing the right CNC machining center is critical. The top five CNC machining centers mentioned above—Haas VF Series, Okuma Genos M560-V, Makino a61nx, DMG MORI DMU 50, and Fanuc Robodrill—each offer unique advantages that optimize production, increase precision, and ultimately bring Greater profitability. various departments.

As technology continues to advance, it is critical for manufacturers who want to stay competitive in today’s fast-paced environment to stay updated with the latest CNC machines and their capabilities. Investing in a quality CNC machining center can bring significant returns, including increased productivity, improved quality and greater flexibility to adapt to changing market demands.

FAQ section

1. What is the role of CNC machining in manufacturing?

CNC machining plays a vital role in the manufacturing industry by enabling precise, automated control of machine tools. This enables the production of complex parts with high precision and repeatability.

2. How do I choose a CNC machining center that suits my needs?

Choosing the right CNC machining center depends on several factors, including the type of materials you use, the complexity of the parts you produce, your production volume, and your budget.

3. What maintenance does a CNC machining center generally require?

Regular maintenance typically includes cleaning, lubrication and regular inspection of components such as spindles, belts and coolant systems to ensure optimal performance and longevity.

4. Can CNC machining centers be used for prototyping?

Yes, CNC machining centers are versatile and can be effectively used for rapid prototyping, allowing designers to create physical models of their designs before mass production.

5. What are the commonly used materials for CNC processing?

Common materials include metals (such as aluminum, steel, and titanium), plastics (such as acrylic and nylon), and composites. Each material has specific properties that make it suitable for different applications.

By understanding the technology and the specific machines you have access to, you will be able to maximize the efficiency of your manufacturing process and achieve outstanding results.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.