Friends often ask, how can I give the parameters of this drill bit? What parameters are recommended for processing stainless steel? Does this question bother all treatment friends? Why is everyone looking for settings?

In fact, the reason is very simple: find a suitable parameter to maximize the performance of the tool, so that the tool life is very long. It’s all about reducing costs.

1

Will everything be fine if you choose the right processing parameters?

In fact, the brand’s cutting tool samples have already indicated the processing parameters of different materials and different aperture ratios, as well as problems and measurements. You can choose the parameters on the samples of some high-quality domestic brands for testing purposes.

The parameters often cannot deviate from the application scenario. After all, we have to face various working conditions during processing, such as the precision of radial drill and three-axis CNC, the precision of the Three-axis CNC and five-axis CNC. , and the treatment is stable. The degree also varies.

It even includes the tightening mechanism. For example, when we process deep holes (10 times the diameter), you choose ER tool holder to clamp the drill bit. If you use a hydraulic tool holder to clamp the drill bit, the precision will be high. be more stable?

In fact, many parameters are discovered through exploration. The sample parameters can only be considered for reference, but they should match different parameters in a specific application scenario.

2

So how do you calculate the actual lifespan of the treatment?

These include new knives and resharpening tools (such as alloy drill bits). Generally speaking, the service life of resharpening tools should reach at least 70%. Of course I’m talking about the average value, sometimes a few tools that reach 90%. % cannot be included. Among them, the factory often requires the tool manufacturer’s products to be absolutely stable.

The calculation formula for our drill is Vc=πDn/1000,

Linear speed Vc (m/min=meters/minute)

Tool diameter D (mm=mm)

Rotation speed n (r/min= revolutions/minute)

Pi (3.14)

The parameters given in the tool catalog are all based on this formula, and finally the other corresponding values are obtained.

Generally, the parameters are compared first, and then the final tool life is tested based on actual machining conditions.

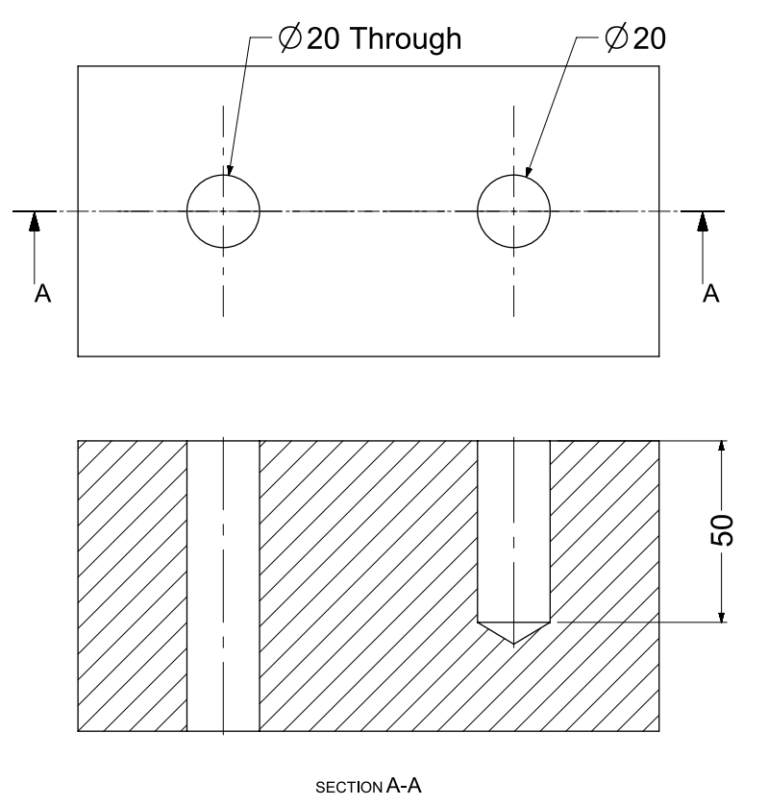

For example, if a hole is 50mm deep and there is only one hole on each part, then 1000 parts are ultimately processed and the final life is 50mm x 1000 parts = 50,000 mm. Converted to meters it is 50,000mm/1000 = 50 meters, so the actual lifespan of this new knife is 50 meters.

The 50 meters mentioned here and the 50 meter linear speed recommended by the settings are not the same thing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.