In CNC milling, vibration may occur due to the limitations of the cutting tool, tool holder, machine tool, workpiece or fixture, which will have certain adverse effects on the accuracy of the workpiece. machining, surface quality and machining efficiency. To reduce cutting vibrations, relevant factors must be considered. The following is a complete summary for your reference.

1

Not very rigid fixation

1) Evaluate the direction of cutting force, provide adequate support or improve mounting

2) Reduce the cutting force by reducing the cutting depth ap

3) Choose sparse-toothed, uneven-pitch cutters with sharper cutting edges

4) Choose a geometry with a small nose radius and a small parallel terrain.

5) Choose fine grain uncoated blades or fine coated blades

6) Avoid machining when the workpiece is not sufficiently supported to resist the cutting force.

2

Part with low axial rigidity

1) Consider using a square shoulder milling cutter with positive cutting geometry (90° lead angle)

2) Choose an insert with L geometry

3) Reduce axial cutting force: smaller cutting depth, smaller tool tip radius and parallel terrain

4) Choose sparse-toothed cutters with uneven pitches

5) Check tool wear

6) Check tool holder runout

7) Improve the tool clamping situation

3

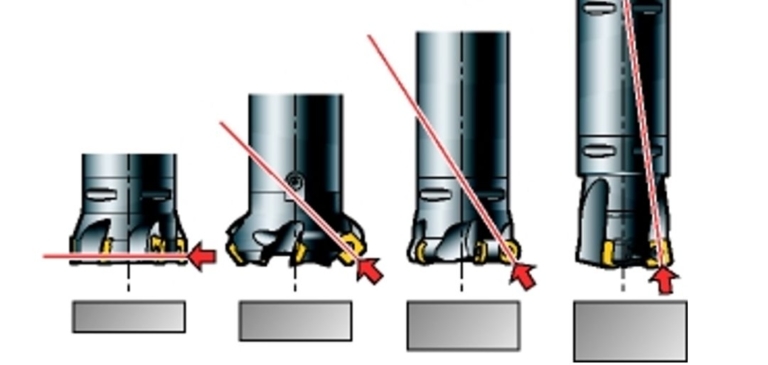

Tool overhang is too long

1) Minimize the overhang

2) Use sparse-toothed cutters with uneven pitches

3) Balance radial and axial cutting forces – 45° rake angle, large tool tip arc radius or round insert milling cutter

4) Increase feed per tooth

5) Use lightweight cutting insert geometry

6) Reduce the axial cutting depth af

7) Use reverse milling for finishing

8) Use extended extension cords with anti-vibration function

9) For solid carbide cutters and interchangeable head cutters, try using a cutter with fewer teeth and/or a larger helix angle.

4

Milling square shoulders with a weak spindle

1) Choose a cutter with the smallest diameter possible

2) Choose lightweight cutters and inserts with sharp cutting edges

3) Try reverse milling

4) Check the spindle deformation to see if it is within the acceptable range of the machine tool.

5

Unstable table power supply

1) Try reverse milling

2) Tighten the machine tool feed mechanism: For CNC machine tools, adjust the feed screws.

3) For traditional machine tools, adjust the lock screw or replace the ball screw

6

Cutting parameters

1) Reduce the cutting speed (vc)

2) Increase power (fz)

3) Change cutting depth ap

7

poor stability

1) Shorten the overhang

2) Improve stability

8

Vibration in corners

Large fillets programmed at lower feed rates

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.