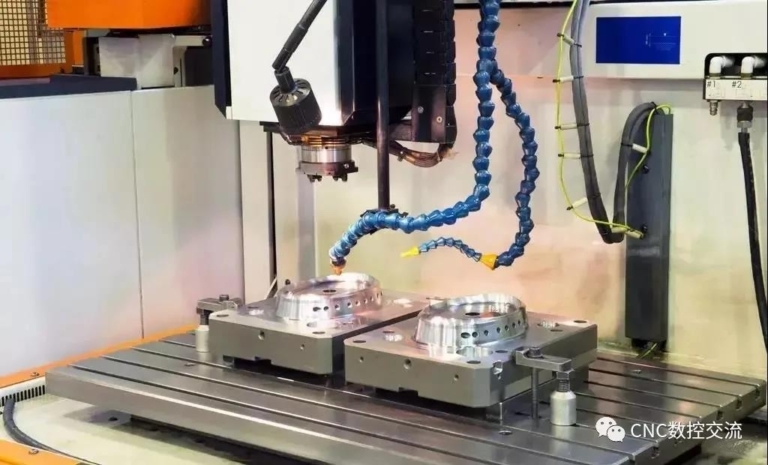

We all know that the precision of the machining center affects the quality of treatment. expenses of these brands.

Factors considered

1. Positioning central vertical machining samples:

The sample must be located in the middle of the X race and placed along the Y and Z axes at appropriate positions adapted to the positioning of the sample and lighting and tool lengths. When there are specific requirements for the positioning position of the sample, it must be stipulated in the agreement between the manufacturer and the user.

2. Specimens fixing:

The sample should be easily installed on special lights to obtain maximum stability of the tool and the lighting. The mounting surfaces of lighting and samples must be straight.

The parallelism between the mounting surface of the sample and the tightening surface of the luminaire must be checked. Appropriate tightening methods should be used so that the tool can penetrate and make the entire length of the central hole. It is recommended to use counterparties to repair the sample to avoid interference between the tool and the screw. The total height of the sample depends on the selected fixed method.

3. Materials, tools and sample cutting:

The materials, cutting tools and sample cutting parameters are selected according to the agreement between the manufacturer and the user, and must be saved.

Cutting speed: the cast iron parts are around 50 m / min; Aluminum parts are around 300 m / min.

Power supply: approximately (0.05 ~ 0.10) mm / braid.

Cutting depth: The radial cutting depth of all grinding processes must be 0.2 mm.

4. Sample size:

If the sample is cut several times, the external dimensions are reduced and the openings are increased. Precision of the machining center. The samples can be used several times in cutting tests, and their specifications must be kept at less than 10% of the characteristic size given in this standard. When the test part is used again, a thin layer cut should be performed before performing a new fine cutting test to clean all the surfaces, then test.

After reading it, I think you can almost know how to judge the precision of a machining center, then list the factors that affect the precision of CNC machining:

1. Precise size of the part and poor surface finish

Cause of the fault: the tip of the tool is damaged and not strong;

Solution: If the tool is not lively after being worn or damaged, enhance the knife or choose a better tool to re-infuse the knife; ; The reason for the crawling machine is to drag the guide rail of the plate, the lead screw ball is worn or loose, and the tool-tool must pay attention to the maintenance. In time to reduce friction; Choose the cooling liquid adapted to the treatment of the part to meet the processing requirements for other processes.

2. The room produces a cone head

Cause of the defect: the level of the tool-tool is not properly adjusted, a top and a bottom, which leads to an unstable placement; Give the way;

Solution: Use a level to adjust the level of the tool-machine, place a solid base and fix the machine to improve its tenacity; seat.

3. The size of the part is different from several millimeters of the actual size, or there is a big change in a certain axial direction.

Cause of the fault: the speed of the fast positioning is too fast, and the reader and the engine cannot react; , and the lock is clear;

Solution: If the fast positioning speed is too fast, adjust the GO speed appropriately and the speed and the cutting time will operate the driver and the engine normally at the nominal operating frequency; The screw crafters are too tight.

If the tool medium is too loose after changing the tool, check if the inversion time of the tool support is satisfied, check if the turbo-ver inside the tool holder is worn, if the ‘space is too large, if the installation is too loose, etc. If it is caused by the program, the program must be changed.

If the dimension deviation is too large, check if the system parameters are reasonably defined, especially if the parameters such as electronic gears and steps are damaged.

4. The arc treatment effect is not ideal and the size is not in place

Failure cause: the frequency of vibrations that overlap causes resonance;

Solution: Discover the components that generate a resonance, change frequency and avoid resonance; is installed firmly and placed gently, slide if the plate is too tight after wear, the space is increased or that the tool holder is loose, etc.;

6. There are changes in the processing of a certain part of the part and the dimensions of other processes are accurate.

Cause of the fault: if the parameters of the program block are reasonable, if they are in the predetermined track, and if the programming format meets the requirements of the manual.

Solution: If there are disorderly teeth in the thread block and the step is incorrect, the peripheral configuration (encoder) of the treatment of the thread and the objective factors of this function will be immediately associated.

8. Each part of the part has an increase or decrease

Cause of failure: program writing errors; The system parameters are unreasonable;

Solution: Check if the instructions used by the program are executed according to the requirements specified in the instructions. Starting point once the program is finished, then run it several times.

Check if the system parameters are defined or are considered to be modified; If the coupling of the gear is uniform and check if there is a periodicity, a phenomenon of regular defect, if there are any, check its key parts and eliminate them.

9. The dimensional changes induced by the system are unstable

Failure cause: adjusting unreasonable system parameters; unstable working tension; Useful signals; signal between the system and the driver’s unusual transmission;

Solution: the speed, the acceleration time is too large, the speed of the pin, the cutting speed is reasonable, that the operator parameters modify it to changes in system performance; Driver’s pulse output point point Add anti-interference absorption capacitors;

Select the appropriate capacitor model; Check if the signal connection line between the system and the driver is protected, if the connection is reliable, check if the system’s pulse signal is lost or increased; .

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.