Milling is a common machining method that uses multi-edged rotating tools to remove material from a part to create various shapes and features. The characteristics of milling processing mainly include planes, grooves, steps, contours, holes, threads, etc. Here are the common characteristics of milling and their processing points:

1.Face milling

Features:

Used to treat large flat surfaces.

Usually a flat bottom cutter is used.

Treatment points:

Choose a suitable face milling cutter, ensuring that the tool diameter is greater than the processing width.

Set the appropriate cutting speed and feed to achieve a good surface finish.

Hold the workpiece steady to prevent vibration from affecting surface quality.

2. Groove milling

Features:

For processing rectangular or T-shaped slots.

End mills are generally used.

Treatment points:

Choose a suitable groove cutter, ensuring that the diameter of the cutter matches the width of the groove.

Set the appropriate cutting depth and feed rate to avoid tool breakage.

Keep the part stable and tight to avoid any movement of the part during processing.

3. Contour milling

Features:

For machining complex curves or contours.

A ball nose milling cutter or a shape milling cutter is generally used.

Treatment points:

Select a suitable contour cutter and ensure that the tool geometry matches the shape of the contour.

Set reasonable cutting parameters to ensure processing accuracy and surface quality.

Write precise CNC programs to ensure tools follow predetermined paths.

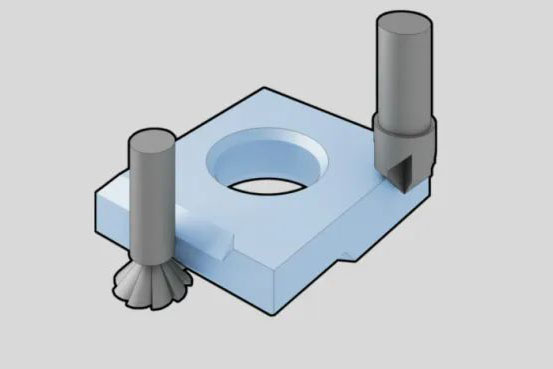

4. Countersinking the inner hole

Features:

For machining holes of different diameters and depths.

A drill or ring grinder is generally used.

Treatment points:

Choose the correct hole cutter, making sure the tool diameter matches the hole diameter.

Pre-drill small holes and then enlarge them to improve hole accuracy and surface quality.

Use cutting fluid to reduce friction and heat buildup.

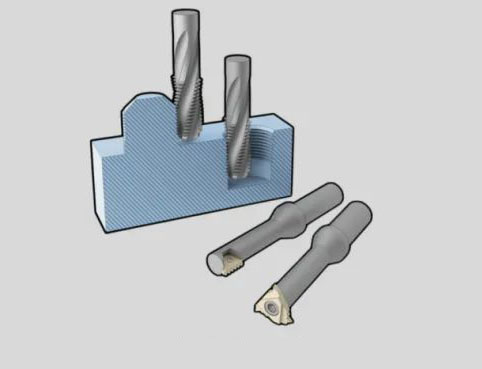

5.Thread milling

Features:

Typically, a thread milling cutter is used.

Treatment points:

Select a suitable thread milling cutter and ensure that the tool specifications match the thread specifications.

Write precise CNC programs to ensure thread shape and size accuracy.

Set reasonable cutting parameters to reduce tool wear and improve processing efficiency.

6. Milling and chamfering

Features:

Used to create chamfers on the edges of parts.

Typically, a chamfer cutter is used.

Treatment points:

Choose a suitable chamfer cutter and make sure the angle of the tool matches the angle of the chamfer.

Set appropriate cutting parameters to avoid uneven chamfering.

Keep the part stable and tight to avoid any movement of the part during processing.

7. Groove milling

Features:

For machining circumferential or spiral grooves.

Special cutters are usually used.

Treatment points:

Choose the right slot cutter and make sure the tool geometry matches the shape of the slot.

Set reasonable cutting parameters to ensure groove depth and width accuracy.

Use cutting fluid to reduce friction and heat buildup.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.