When tapping threads on parts in the mechanical processing industry, problems sometimes arise due to unreasonable processes (the workpiece with threaded holes is welded and then the end face of the threaded hole is processed), personnel of processing makes errors in reading the drawing (wrong size) or operating errors (calculation errors, drilling shallow holes, programming errors and incorrect positioning of the depth of drilled and tapped holes) and many other factors lead to the phenomenon that the threaded holes on some parts are not deep enough. once the treatment is completed.

Once such problems occur, due to the poor stability of the drilling machine, operators and process technicians often directly install the workpiece with the threaded hole to be repaired on the boring or milling machine bench. After correction and tightening, the bottom hole of the threaded hole. The drill bit is used according to the correction of the inner diameter of the threaded hole, drill the bottom hole to the depth of the pattern, and then use a tap to repair the thread. However, this method can easily cause the operator to “friction cut” the original thread during the bottom hole deepening process, damaging the existing thread and affecting the processing quality of the threaded hole.

At the same time, this repair method requires the operator to have a good technical level, the process of correcting threaded holes takes a long time, and the work efficiency is very low. The cost of repairing it with drilling and milling equipment is also relatively high. In addition, if the end face of the threaded hole is not perpendicular to the center line of the threaded hole due to reprocessing after welding or other reasons, it will inevitably damage the existing threads during secondary drilling of the threaded bottom hole. which will inevitably lead to hidden danger of scrapping or damage to the threaded hole of the part. After many discussions and experiments, the author found a series of tricks that are more efficient, more reliable and more stable in quality.

1. How to Repair Shallow Threaded Holes on a Radial Drill

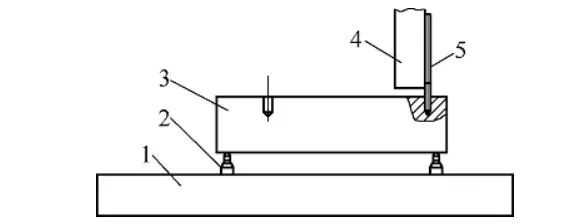

If the workpiece material is of high hardness, you can drill and tap it on a radial drill when repairing its threaded holes. However, it is necessary to first correct the center line of the threaded hole to be parallel to the center line of the drill spindle as shown in Figure 1, and then directly use a drill to correct the coaxiality from the center line of the threaded hole and the drill shaft of the drill, and use a drill bit and tap to meet the required dimensions. Drill and tap shallow threaded holes.

1. Workbench 2. Adjustable screw 3. Workpiece 4. Drill spindle 5. Correction screw

Steps to repair the threaded hole: Firstly, place the workpiece on the adjustable screw which has been arranged on the drill press workbench. Second, screw the correction screw into the threaded hole to be repaired and tighten it to ensure that the center line of the threaded hole is fixed. the correction screw is aligned with the threaded hole to be repaired. The center lines of the threaded holes are consistent, then move the drill spindle closer to the correction screw (a space should be left to prevent the spindle from drilling) machine from tightening the correction screw and affecting the correction accuracy) , and adjust the adjustable screw so that the correction screw is parallel to the drill spindle, gradually. Adjust the slope to ensure that the parallelism error is not more than 0.03mm. You can use a piece of paper to pull the upper and lower parts between the drill spindle and the correction screw to evenly tension it. Finally, install the drill; chuck on In the spindle of the drill, clamp the modified drill bit into the chuck, insert the drill bit into the threaded hole to be repaired, observe that the clearance between the handle and the threaded hole is uniform, drill according to the required size, and complete drilling . Simply replace the faucet with the screw.

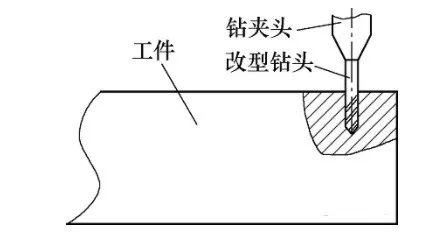

The production of modified drill bits is very simple. Just grind the length of the blade of an old drill bit as long as possible. The straight part of the shank is evenly ground or diverted 1mm, so that there is a gap of 1mm between the original threaded hole and the threaded hole during drilling, so that no damage to the threads existing threaded hole does not occur.

The precision requirements of the correction screw are relatively high. The threaded part must be coaxial with the straight shank part and must not be bent. Its length is generally 3 to 5 times the depth of the thread to be repaired to ensure the precision of the correction.

2. How to Repair Shallow Threaded Holes with a Drill Gun

For larger, heavier, softer parts (such as aluminum alloy parts) that need to repair the problem of shallow threaded holes with smaller diameters, a pistol drill can be used to hold the modified drill bit above and drill it directly, then tap. the wire manually (see Figure 2).

3. Conclusion

The method of repairing small threaded holes is very innovative, especially the use of modified drill bits that are turned and ground from old drill bits. This is actually a small invention that not only reuses waste, but also solves a difficult but real problem. the problem of industry. In the actual production process, the problem of repairing shallow threaded holes can be effectively solved. The process is simple, practical and can be popularized.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.