The development of technology always exceeds our expectations. Sometimes humans are deeply worried about the stagnation of physics and worry about the premature arrival of the “scientific singularity”; sometimes rapid advances in new technologies suddenly cause panic, like the recent explosion of ChatGPT. Once again, humans are tortured: “Will we soon be replaced by artificial intelligence? Will this really destroy humanity?” Digital life in the film “The Wandering Earth 2” sent shivers the public and secretly scare them When artificial intelligence actually appears as a versatile writer and problem solver, I believe many people think of the 550 W quantum computer that “wipes out humanity to preserve humanity. human civilization”. Of course, the value of human beings lies in their irrationality, impulsiveness and delicate emotions. Technology has been developed by humans, and it can and will only become an aid to humans. transform the world.

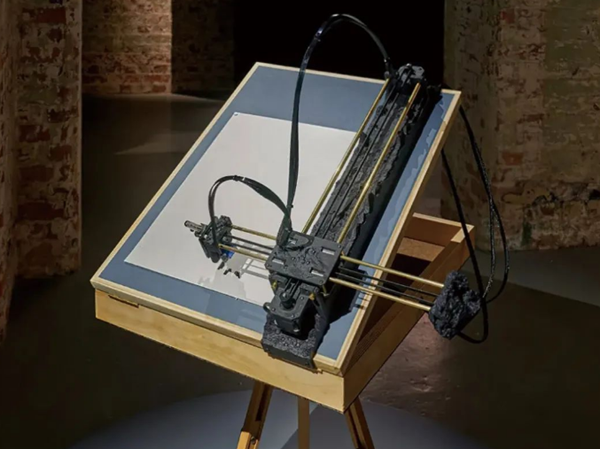

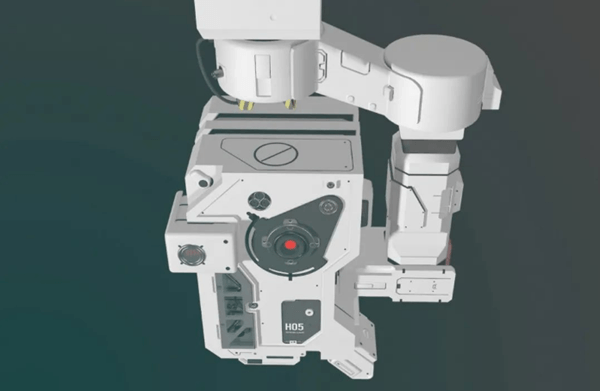

The films “The Wandering Earth” and “The Wandering Earth 2” use a large number of 3D printed props. The image shows the intelligent quantum computer MOSS in the film. Image: CGtrader.

For those in the art world, a technology that seems less advanced – 3D printing – has continued to receive increasing attention in recent years. What changes has 3D printing technology brought to the art world? How do artists benefit?

Bruce Beasley’s “Coriolis” sculpture made using 3D printing technology Photo: businesswire.

As early as 2013, when the famous sculptor Bruce Beasley was invited by the software platform Antodesk to organize an exhibition of 3D printing works in San Francisco, his enthusiasm was indescribable: “Computer modeling and 3D printing give me the possibility to make sculptures. It was previously impossible, regardless of the tools the artist uses, the impulse to create is the same, but the exploration of new artistic languages, whether mechanical or organic, is ultimately made possible through the technological innovation. It’s liberating for artists.

Yes, since the mass availability of consumer printers in the early 2010s, the lives of artists and designers, represented by sculptors, have become easier. Many artists who previously struggled to bring specific concepts to life due to material and manufacturing constraints are now free to explore the new terrain of opportunity that is 3D printing. Whether it’s customization, versatility, sustainability or cost reduction, 3D printing has long proven to be a valuable aid to artists in the creative world. In addition to precise modeling, with the emergence of 3D printing, many contemporary artists use it to replace or supplement the original materials for creating sculptures, thereby further exploring the enormous possibilities of 3D printing .

The 3D printer used by artist Xu Fanghua to print the installation work “Moon”Image: Tai Kwun Museum of Contemporary Art

Black Lunch Installation by Jacoby Satterwhite 2020 Image: Vimeo

The role of experimentation in contemporary art is crucial. In the field of artistic production, 3D printing makes many impossible things possible, providing artists with a new medium: resin, even if it still has many material defects. In his 2020 work “Black Lunch,” New York artist Jacolby Satterwhite combines 3D-printed resin fragments and neon lights to create a scene from 19th-century French modernist painter Édouard Manet’s “Meadow” Served Lunch that introduces a charming contemporary theme. 3D printing also brings surprising textures to contemporary works of art. In 2021, Chinese artist Xu Fanghua’s installation work “Moon” exhibited at the Tai Kwun Museum of Contemporary Art in Hong Kong used carbon black powder material to 3D print the craters on the surface of the moon, adding an incredible sense of reality to the work.

Reikli Tiravani Untitled 2013 3D printing installation 2013Image: Artistic

Of course, sculpting artists can benefit more from 3D printing technology. They use their imagination to continually explore the perspectives and possibilities of this technology. Rirkrit Tiravanija, a Thai sculptor born in Argentina, used 3D printing to create branches and leaves in a bonsai in his mixed media work “Untitled 2013” as early as 2013. Later, using the same technique, he created “Untitled 2017″, which shined at the Venice Biennale the same year, drawing the world’s attention to Thai contemporary art. 3D printed art has even made its way into space. In February 2022, the Netherlands’ Moon Gallery sent a batch of 3D prints designed by Singaporean artists Lakshmi Mohanbabu and Matteo Seita to the International Space Station. The work “Structure and Reflection” uses the combination of technology and art to demonstrate the “unity of”. humanity”.

3D model of the bust of Nefertiti at the Neues Museum in BerlinImage: open culture

Of course, for those producing fine art reproductions, 3D printing technology can also be used to significantly increase production efficiency. After carrying out detailed analyzes of the texture of the originals, they were able to obtain precise data on the surface height of the paintings. After secondary printing (3D printing + ordinary printing), they can obtain a replica almost identical to the original. Of course, this type of simulated and real technology can be better applied to the protection of cultural relics. Back in 2016, two German artists secretly scanned the bust of Nefertiti, a treasure from the Neues Museum in Berlin, and posted the 3D model online for anyone to download. The German and Egyptian governments have long argued over this ancient Egyptian sculpture. It might not be a bad choice for the Egyptian museum to 3D print an identical statue for display while the dispute is not yet resolved. While humans cannot guarantee the adequate protection of all the fine arts of human civilization, 3D scanning and printing technology must be the most practical and effective way to preserve cultural relics. Additionally, 3D printing can even help “revise” a more understandable timeline of art history.

In 2015, the Prado Museum in Madrid, Spain, collaborated with Edios Durero, a studio specializing in 3D printing, to reproduce several masterpieces by Velasquez and Goya, creating a museum for blind and visually impaired. of course, impossible in the past. As of 2021, Getty Images is even working with the American Blind and Tactile Image Federation to convert over 45 million images into tactile 3D prints so that people with visual impairments can also experience art. After the National Museum in Rio de Janeiro, Brazil was destroyed by fire, 3D printing technology used the original data to reconstruct many cultural relics, which can indeed be called “reconstructing the history of the Brazil.”

Today’s 3D printers can handle large projects. The photo shows the WASP company 3D printing buildings. Photo: WASP.

The application of 3D printing technology in other fields is no longer a novelty. As 3D printers unlock more materials, the modeling process is almost completely changed. In 2021, the luxury brand Dior opened a boutique in Dubai. The building was entirely printed by Italian 3D printing company WASP using natural materials including clay, sand and rice husks. Yves Béhar, designer and founder of Fuseproject, had even more ambitious plans in 2019, announcing a partnership with the non-profit New Story Charity to create projects in South America. Poor people built 400 3D printed houses. In the design of scenes and cinema scenes, 3D printing technology is more popular. In 2017, WASP printed the entire set of the 19th century drama “Fra Diavolo” at the Rome Opera. In the movie “The Wandering Earth 2”, in addition to heavy machinery sponsored by many companies, a large number of heavy transport vehicles, mine bodies, cool robotic arms and future helmets were all made using the 3D printing and post-production. In processing, advancements in material science have made it possible to use various materials such as metal and plastic in 3D printed props, ensuring the outstanding visual effects of the film and achieving the historical status of this film of Chinese science fiction. In jewelry design and production, 3D printing technology can retain the designer’s most complex designs to the greatest extent and complete many styles that cannot be completed by manual carving, which has completely changed the jewelry market. jewelry.

Yves Béhar’s 3D printed house model in South America Photo: New Story Charity

In recent years, we have seen the emergence of 3D printed art as a form of creative expression. Artists use their imagination to advance their thoughts and help us see things from a different perspective. Along the same lines, 3D printing has broken boundaries in all aspects of design and manufacturing. Integrating and creating 3D printing and art is just the natural next step. But another question arises: is 3D printing a threat to traditional art, particularly sculpture and installation art?

Sculpture is one of the most established art forms. It requires creativity and superb skills, requires the artist to come up with interesting structures or objects, and is an undisputed art form. However, with the development of 3D printing technology, this artistic tradition appears to be under threat. As 3D printers become cheaper and easier to use, reconstructing a sculpture seems less difficult. Many companies offer 3D printing services. Traditional sculpting techniques and methods may not be as popular, as it is possible to create impressive sculptures, including the most complex and crazy shapes, simply by using 3D modeling and rendering software. There are many reasons why 3D printing poses a threat to sculptors, but traditional sculpting art cannot disappear because of 3D printing.

The Dior store building in Dubai made with 3D printing technology Image: 3Dprint.com

First of all, 3D printing is more of a science than an art and involves using technology to create products in three-dimensional space. The science of 3D printing technology becomes even more evident due to the different processes involved. 3D printers must extract detailed information accurately, and any errors in the data will be reflected in the final product or cause printing to stop. Yes, 3D printing can create works of art, but the objects it produces are more commonly thought of as mass-produced products. Unless true creativity is involved and the object created does not come from copied data, the “art” of 3D printing will simply be seen as a form of fine craftsmanship – much like “the digital art” that floods the Internet. They are far from the spirituality (Aura) of created art in the traditional sense – as Walter Benjamin explained in “The Work of Art in the Age of Mechanical Reproduction”. 3D printing itself is only part of the process of creating sculptures. It is not an art in itself and cannot be compared to the process of creating works of traditional sculptors.

Second, just like digital artists using Photoshop or Illustrator to draw digital images, technology-assisted art creation will never replace creativity itself. With the popularity of these graphic production and editing software programs, will today’s people’s drawing skills decline significantly? The answer is obviously no. Even with high-quality printers, computer-generated art still cannot make traditional painting obsolete. After all, there is no such thing as an outdated “method” in art. The same thing happens in photography. Until now, film photography remains the first choice of many photographers. All we can say for now is that technology complements traditional methods and, in some cases, traditional artistic production.

The precision brought by the combination of advanced software and hardware does not represent a death sentence for traditional craftsmanship. In fact, people are more likely to find minor flaws in the artwork they collect because they always prefer uniqueness. Things that can be created quickly using a computer and special equipment may impress the average person, but they will never interest serious collectors and art critics.

Many people often associate objects generated by 3D printing with art, but the likelihood of 3D printing replacing traditional sculpture is slim. It cannot even completely replace traditional manufacturing without personal creativity, without singularity and without “soul”. 3D printing technology is not a threat, nor something to be afraid of. The advantages of 3D printing are that it allows artists to create stunning sculptures directly from the computer, is less expensive than traditional methods, and provides artists with more freedom and flexibility . Additionally, 3D printing offers artists the ability to experiment with new materials and techniques more quickly. 3D printing is changing the outcome of art creation by giving artists more freedom to create anything they can imagine. 3D printing also makes it possible to create interactive works of art that can be touched, held at low cost, and even worn. 3D printing can offer countless benefits, but when it comes to art, the benefits may not be as numerous. Even a 3D printed golden bull cannot replace the memory left on the rock wall of Lascaux Cave by primitive man after courageously and wisely capturing the beast. It’s the same point that’s been made countless times: it’s ultimately all about human emotion and creativity. “A civilization without people has no meaning.”

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.