Formnext is the perfect place to discover innovation, whether in 3D printing, software or materials. Currently in the field, our team has noticed numerous use cases, particularly in the field of metal 3D printing, whether in the aerospace, automotive or medical fields. Here are the most notable examples we found this year.

InssTek Multi-Material Nozzle

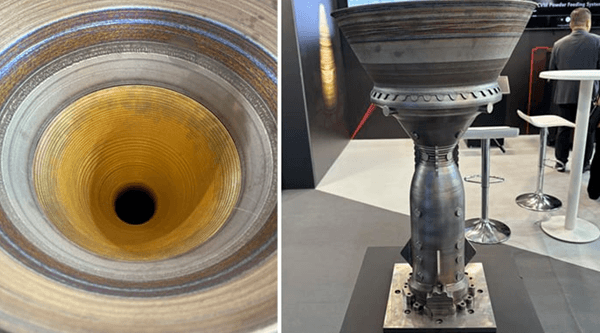

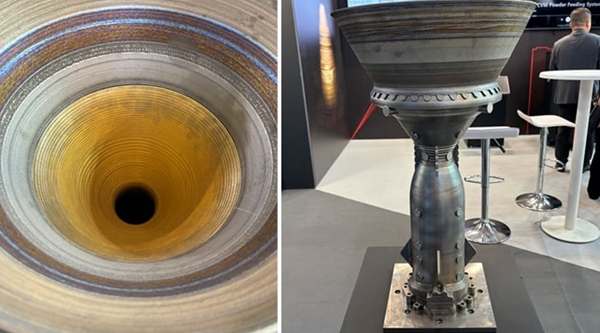

existAmong the applications that caught our attention at Formnext, the multi-material rocket nozzle presented on the InssTek stand was particularly interesting. Production of the three-ton part (301 x 201 x 567 mm) took 600 hours and its expansion (432 x 270 x 169 mm) took 64 hours, both produced by 3D deposition printing (DED). ), in collaboration with the Korea Aerospace Research Institute (KARI). Each part is made from the materials best suited to each component, a feature made possible by InssTek’s DMT technology. For example, the inner part of the nozzle is made from aluminum bronze, with cooling channels spaced just 1mm apart, while the outer part is made from Inconel 625. The extension is made from C-103, a particularly popular material today in the aerospace industry.

The resulting unified parts are interesting because the combination of different metals exploits the strength of each metal, allowing the design of complex structures with advanced functionality. These innovations help improve the efficiency and reliability of rocket engine components. according toInssTek says this advancement is the result of extensive testing, including successful combustion trials. To ensure reliability across multiple materials, each component is manufactured after extensive analysis using MX-Lab, including tensile strength and thermal conductivity testing. These advancements promise to provide customized solutions capable of addressing the complex challenges of modern aerospace. The Korean aerospace sector has thus reached an important milestone, paving the way for further advances in the use of additive manufacturing for aerospace propulsion. You can learn more about InssTek’s solutions here and at Formnext Hall 12.0, Stand D98.

picture1: InssTek’s multi-material rocket nozzle shown inside (left) and outside (right).

to useMetal 3D printing to manufacture high-end electric motorcycle frames

we wantAnother application highlighted at Formnext comes from Farsoon Technologies, an Asian company specializing in metal-polymer 3D printing solutions. Farsoon Technologies has partnered with Stark Future to develop high-performance, scalable manufacturing solutions for the premium electric motorcycle market. A clear example of this collaboration is a complete motorcycle frame made from titanium alloy using Farsoon’s FS721M-H-8-CAMS 3D printer. This metal industrial solution is designed to meet large format production needs, offering a print volume of 720 x 420 x 650 mm.

It also comes with eight1000 W fiber laser that optimizes productivity while reducing production costs. The system also integrates Farsoon’s CAMS solution, which uses a unique dispensing system and interchangeable ink cartridges to ensure continuous production and minimize downtime between prints. If you would like to experience this metalwork for yourself, please visit Formnext Hall 11.0, Stand E11. For more information, you can visit the Farsoon Hi-Tech website.

picture2: 3D printed motorcycle frame (left) and Farsoon high-tech technology (right).

FIDENTIS and its multimetallic prosthesis

The use of additive manufacturing in dentistry is not new, but metalThe use of 3D printing in this area is still somewhat unusual. This is where FIDENTIS stands out. Fraunhofer startup IGCV has developed a multi-material powder bed laser fusion solution particularly suited to the manufacture of dental prostheses. The technology combines a powder bed with a robot capable of depositing additional materials, allowing two or more alloys to be processed simultaneously. For this particular application, this involves using molten CoCr and gold on the friction surface. FIDENTIS claims this process is 20 times faster and 60% cheaper than traditional methods. The application was well received, making the company one of the finalists for Formnext’s 2024 Rising Star Award. Visitors will be able to discover these multi-material prostheses on the Fraunhofer IGCV stand.

picture3: Metal prostheses exhibited at Formnext.

Musician In-Ear Headphones

In-ear headphones are essential for musicians and singers because they allow them to hear what is happening on stage. But did you know that they can be used not onlyCan 3D printing manufacturing also use metal fabrication? The Bright Laser Technologies (BLT) booth showcased metal in-ear headphones produced using the BLT A160 500W 3D printer. Designed by EarFit, a company specializing in premium acoustic solutions for musicians, these titanium in-ear headphones (160mm x 160mm x 160mm) are designed to deliver personalized, high-quality, reliable “crystal-clear” sound . clear. 3D printing was chosen due to its ability to create more cost-effective, reliable and practical solutions that transcend the limitations of traditional manufacturing methods.

picture4: Titanium in-ear headphones on BLT support.

Renishaw bikes win Olympic medals

The Paris 2024 Olympic Games are now a thing of the past, but you can still find exciting apps at Formnext. British manufacturer Renishaw has revealed a track bike developed in partnership with British Cycling, Lotus Engineering and Hope Technologies which helped win eight medals at this year’s Olympics. This bike is particularly interesting because it contains parts 3D printed using Renishaw’s RenAM 500Q, including a titanium seat post and crankset. The crankset is designed from Ti6Al4v with an internal lattice structure that combines strength and lightness to meet the bike’s strict performance requirements. Demonstrate how 3D printing can transform advanced cycling equipment.

picture5: Gold medal bike with metal crank.

The largest in Finland3D printed metal parts unveiled at Formnext 2024

With Northern Europe inAt the center of Formnext 2023, we were able to see how additive manufacturing is developing in the region. It is making its comeback at Formnext 2024 with a new pavilion in Hall 11.1. Here we can find an interesting application: the largest pressure vessel in Finland, made of 3D printed metal. The component weighs 300 kg, has been tested according to EN 13445-3 and is made of acid-resistant stainless steel using WAAM technology. It has a diameter of 900mm and a height of 1,600mm and has been pressure tested up to 111 bar, well above the 10 bar pressure for which it was originally designed. The project is the result of a collaboration between ANDRITZ Savonlinna Works Oy and the FAME ecosystem, with non-destructive and destructive testing carried out by LUT University.

picture6: Showing the inner (left) and outer (right) parts.

E-Plus and LEAP 71 unveil the world’s largest metal-printed rocket booster

Apart fromBesides InssTek’s multi-material nozzles, we are particularly fascinated by the rocket boosters developed by E-Plus and LEAP 71. The company estimates that this 200 kN model is the largest 3D printed metal rocket booster in the world. world. In one piece, over 1.3 meters high.

The propellant is powered by cryogenic liquid oxygen and kerosene and isAn improvement over the LEAP 71’s Noyron TKL-5 rocket engine, which they successfully launched in June while increasing power by 40 times. It is made from high performance aluminum alloy AlSi10Mg on a DMLS Eplus3D EP-M650-1600 printer. The special feature of this project is the possibility of integrating several components of a rocket booster, such as combustion chambers, nozzles, cooling channels, manifolds and structural elements, into a single component. This approach can significantly reduce the time required for quality assurance because each component no longer needs to be tested individually.

picture7: Rocket Booster exhibited at Formnext 2024.

Coke tower five outlet nozzles

One of the latest metal applications presented at Formnext is a nozzle designed specifically for coke oven cells. To better understand, a coke oven battery is a set of ovens used to convert coal into coke, a carbon-rich fuel that is vital to industries such as iron ore smelting, stoves and blacksmithing. This five-outlet nozzle was developed by ArcelorMittal in partnership with TheSteelPrinters. It combines five individual nozzles into one assembly, simplifying maintenance and increasing efficiency. In addition to custom designs, the solution reduces manufacturing time from four months to three weeks. The material used, AdamIQ3167L, was designed by TheSteelPrinters, specialized in metal 3D printing, and is optimized for the LPBF process. The work weighs 8 kilograms and measures 73 x 300 x 228 mm. You can find it on the ArcelorMittal stand in Hall 11.0.

picture8: Carefully observe the 5 nozzle assembly

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.