1. Overview of grinding technology

Manufacturing industry is the foundation of a country, a tool to rejuvenate a country, the foundation of a strong country and is the main pillar of the national economy.

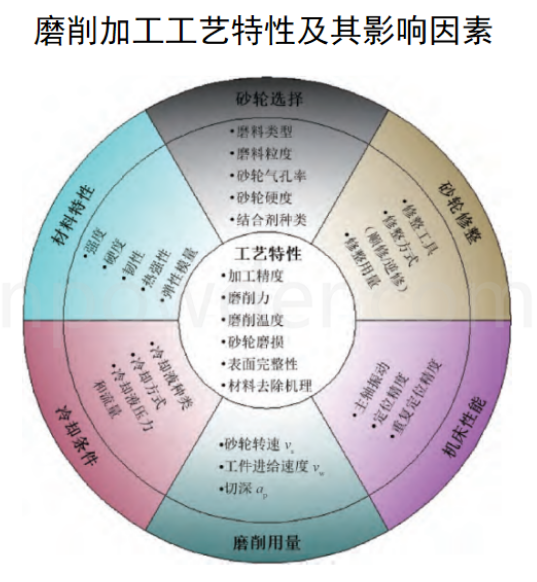

Grinding is a processing method that uses harsh abrasives to remove excess material from the workpiece. Grinding can process materials of any hardness and has irreplaceable advantages in micromachining. It is mainly used for finishing mechanical parts in the manufacturing and equipment field. has a significant impact on the surface quality of parts. It plays a key role and provides important support for the development of modern equipment manufacturing industry.

With the rapid development of aerospace, weapons, precision instruments, semiconductors, new energy and other fields, high-performance materials such as titanium alloys, high temperature alloys, Composite materials and technical ceramics are increasingly used.

Titanium alloys have high specific strength, good high temperature resistance and good corrosion resistance. The amount of fan and compressor components used in aerospace engines with an operating temperature of approximately 350 °C represents approximately 33% of the engine mass.

Nickel-based superalloys have excellent high-temperature mechanical properties and are mainly used in engine combustion chambers and high- and low-pressure turbine parts with operating temperatures above 1,250°C. Their use represents 40 to 50% of the current mass. commercial aeronautical engines.

The density of fiber-reinforced ceramic matrix composites is only 1/3 to 1/4 of that of high-temperature alloys, and their high-temperature strength is better. They are suitable for use as braking materials for nozzles of rocket engines, fighter jets or. high-speed trains.

Metal matrix composite materials have special properties that alloy materials do not have. They are expected to appear in many fields such as spacecraft structures, third-generation solid-state thermal management devices, inertial devices, space optics. equipment and light nuclear protection. Massive demand.

Engineering ceramics represented by alumina, zirconia, silicon carbide and silicon nitride have high temperature resistance, wear resistance, corrosion resistance, good chemical stability and unique functions such as as electricity, heat, light and magnetism. They are widely used in emerging strategic areas. industries. The potential for application in key components of the field is enormous.

These high-performance, difficult-to-machine materials are increasingly used in high-end manufacturing. Key parts require extremely high precision, and the poor grindability of materials poses serious challenges to the grinding process.

Therefore, high-precision manufacturing of high-performance surfaces from difficult-to-machine materials has become an inevitable technical bottleneck.

2. Advanced grinding technology

Efficient grinding

Grinding has unparalleled advantages in machining accuracy and surface roughness, but its material removal rate is low and it is difficult to compete with turning, milling, etc.

In order to improve the grinding efficiency, it is mainly to increase the number of effective abrasive grains per unit time (such as high-speed grinding, ultra-high-speed grinding), increase the area of contact grinding (such as slow feed grinding, end face grinding), and increase the grinding time (such as worm wheel grinding, grinding wheel grinding multi-grinding wheels), increasing abrasive load (such as high load grinding, point grinding), reducing auxiliary time (such as compound grinding, CNC grinding) and other measures.

High-speed grinding, ultra-high-speed grinding

High-speed grinding (grinding wheel speed above 50m/s) and ultra-high-speed grinding (grinding wheel speed above 150m/s) can greatly improve the grinding efficiency, grinding quality and grinding quality. durability of the grinding wheel.

At present, domestic large- and ultra-high-speed grinding technology is still mainly used for processing individual parts such as automobiles, compressors and semiconductors. However, in traditional manufacturing industries such as steel, bearings, gears, agricultural machinery and aviation. , and ships, the popularity of high-speed grinding is still very low.

Breakthroughs in key technologies for ultra-high-speed grinding equipment rely on collaborative innovation in many important areas such as high-end electric spindle technology, hydrostatic bearing technology, ultra-high-speed grinding wheel technology. high speed, sensing technology and high-end CNC. systems.

Spot sanding

Spot grinding is a new development of high-speed grinding technology. It is an efficient processing technology that integrates three advanced technologies: CBN superabrasive grinding, high-speed grinding and CNC flexible processing.

Features: It not only has the advantages of high-speed grinding and ultra-high-speed grinding, but also is similar to CNC turning. It has large grinding depth, low normal grinding force, sufficient cooling and chip removal, low grinding temperature. easy operation, etc., especially suitable for processing thin shaft parts is an excellent combination of grinding technology and CNC technology.

Slow feed deep cutting and efficient deep grinding

Compared with ordinary surface grinding, slow feed deep grinding refers to a grinding method in which the workpiece feed speed (0.05 ~ 0.50 m/min) is lower and the grinding depth (0.1 ~ 30.0 mm) is larger.

Efficient deep grinding is based on slow feed deep grinding and further integrates CBN superabrasives and high-speed grinding technology to increase the workpiece feed speed (0.5 ~ 10.0 m/min) and significantly improve grinding efficiency, known as. “the highlight of modern grinding technology”.

Slow feed deep grinding technology and high efficiency deep grinding technology have the characteristics of grinding arc length and can be processed and formed at one time in the grinding process, high pressure forced cooling, continuous training and others. related technologies are used, which have high grinding efficiency (up to ordinary grinding times up to thousands of times), good surface retention, high grinding wheel durability, etc.

Particularly suitable for shape grinding and cutting grinding, such as blade tenon teeth, gear surface, connecting rod joint surface, rotor groove, caliper sliding groove, chuck guiding, tool groove, screw spiral groove grinding, packaging cutting, stone cutting; and grinding, etc.

Worm wheel grinding

The worm grinding wheel is based on the principle of helical gear transmission. The grinding wheel and gear mesh and rotate in space to achieve continuous indexing and generation grinding of the gear. The grinding wheel has good rigidity, many grinding contact points and high processing. efficiency, good grinding precision and excellent surface quality.

At present, worm wheel grinding technology is mainly used for the mass production of small and medium module gears.

Heavy duty grinding

Main technical characteristics

1) The grinding force is large and it is the grinding technology with the largest load (10 ~ 30 kN) and the highest processing efficiency (500 ~ 1000 kg/h) among all grinding methods. grinding;

2) The working environment is harsh, it is mainly used at high temperatures, and the original shape of the part fluctuates greatly;

3) The requirements for processing precision and surface roughness are not high, and the grinding wheel does not need to be dressed.

Intensive grinding is mainly used to grind the surface defective layers of steel billets and steel plates (cracks, slag inclusions, scars, pores, decarburized layers, scale, etc.). The grinding power has reached 100~300 kW and the grinding wheel. the speed is 80 to 120 m/s. The main evaluation indicators are grinding efficiency and grinding wheel life.

Passive, high-speed grinding of wheels and rails

High-speed passive grinding is a new wheel-rail grinding technology developed in recent years. During operation, the grinding wheel itself is not powered. The movement and pressure of the grinding car causes extrusion, rolling, friction, plowing and cutting between the outer circle of the grinding wheel and the rail of the grinding wheel. is adjusted according to the angle between the two. Rotational speed and texture of the wheel-rail surface.

The biggest advantage of high-speed and passive grinding is the fast grinding speed (60~80km/h), which is not only high efficiency, but also good quality and low cost. It is particularly suitable for lines with dense traffic.

compound grinding

Compound processing is to concentrate the related processing procedures of parts on the same machine tool to achieve the goal of efficient processing or precision processing. There are 2 main types of compound sharpening.

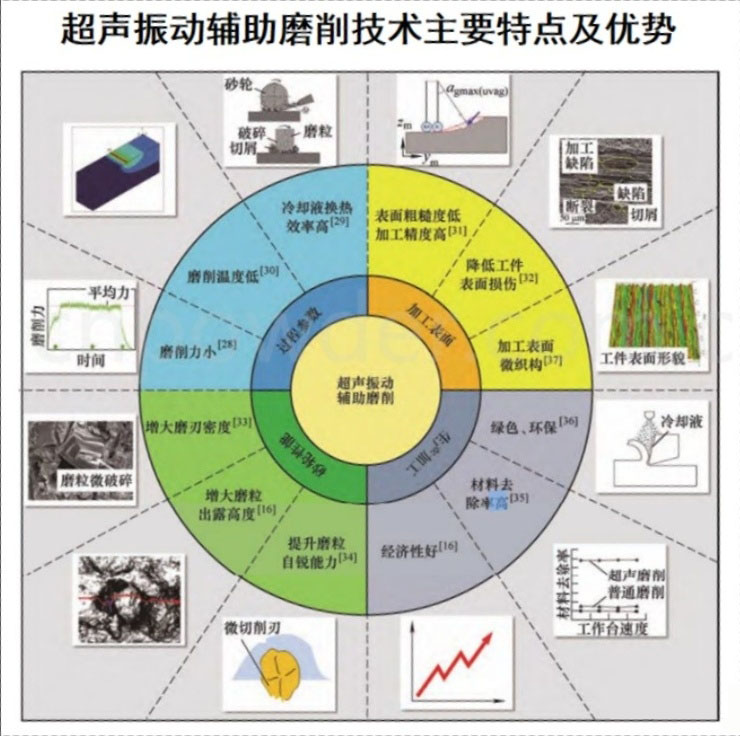

1) A method of combining or superimposing multiple processing methods on a single station, such as ultrasonic grinding, electrolytic grinding, EDM mechanical compound grinding, UV-assisted grinding, magnetorheological polishing, etc.

2) Compound grinding centers mainly appear in the field of engineering applications. They rely on flexible and modern CNC systems to realize concentrated multi-tool and multi-process grinding ideas with just one clamping.

Ultrasonic vibration assisted grinding technology

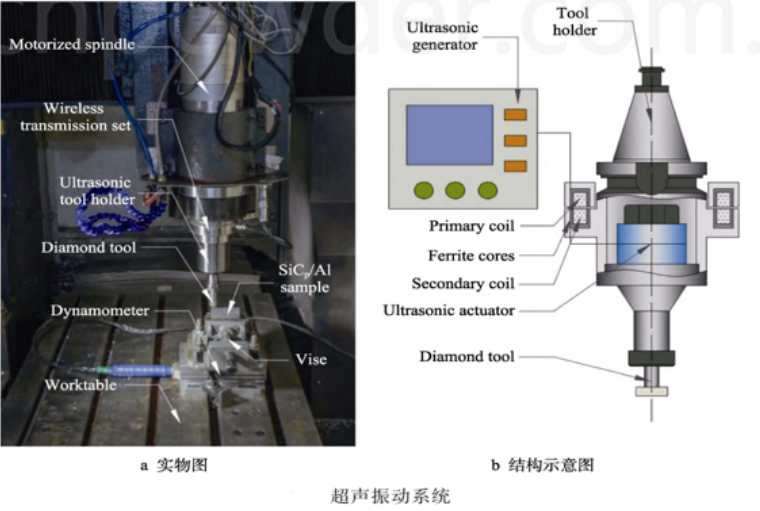

Ultrasonic vibration-assisted grinding is a composite processing method that superimposes high-frequency vibrations on the movement trajectory of abrasive particles and removes material through the impact of abrasive particles and workpiece material. The ultrasonic vibration system mainly includes ultrasonic generators, transducers, horns and grinding tools.

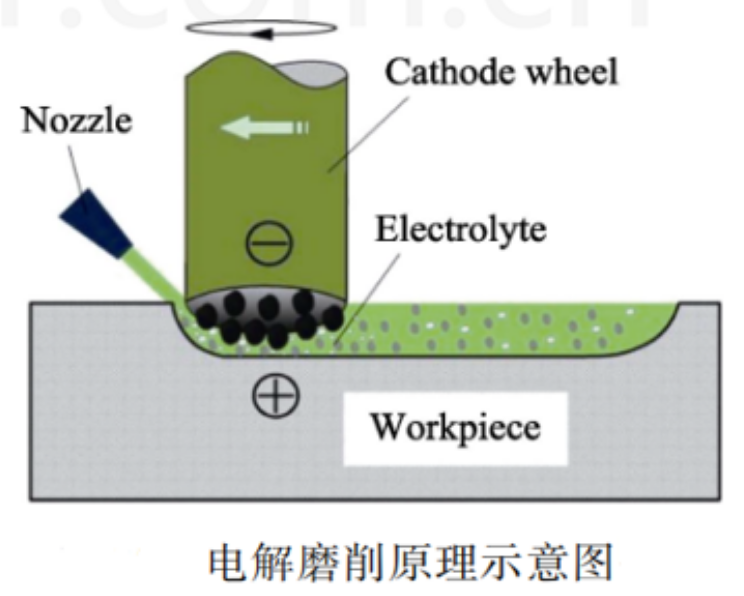

Electrolytic grinding technology

Electrolytic grinding, also known as electrochemical grinding (ECG), has great advantages in processing difficult-to-machine metal materials such as titanium alloys and nickel-based high-temperature alloys. It can reduce the grinding force and grinding temperature, and significantly extend it. the lifespan of the grinding wheel. It has great practical value in high-efficiency grinding of large margins.

Electrolytic grinding can also process carbide and![]() Team-reinforced metal matrix composites. Most hard and brittle materials have poor electrical conductivity and are therefore not suitable for electrolytic grinding.

Team-reinforced metal matrix composites. Most hard and brittle materials have poor electrical conductivity and are therefore not suitable for electrolytic grinding.

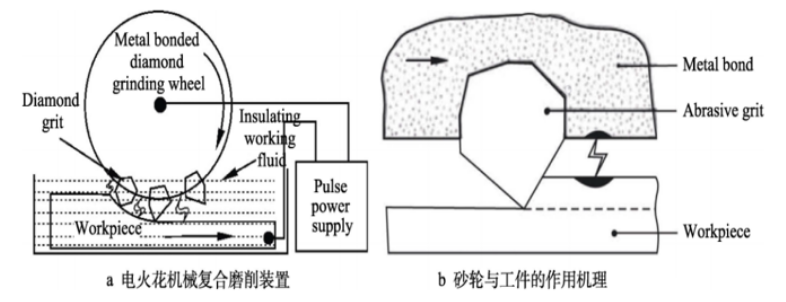

Electric spark mechanical compound grinding technology

Electric spark mechanical composite grinding (EDDG) is based on electric spark grinding, replacing the graphite grinding wheel with a metal bond diamond grinding wheel. The discharge action causes a softened recast layer on the workpiece surface and the abrasive grains from the grinding. The grindstone continues to remove heavy metals. The cast layer forms a new processing surface, allowing the discharge to continue at the same time, the metal bond of the grinding wheel is also eliminated due to the discharge, which is equivalent to online sharpening of the grinding wheel. millstone.

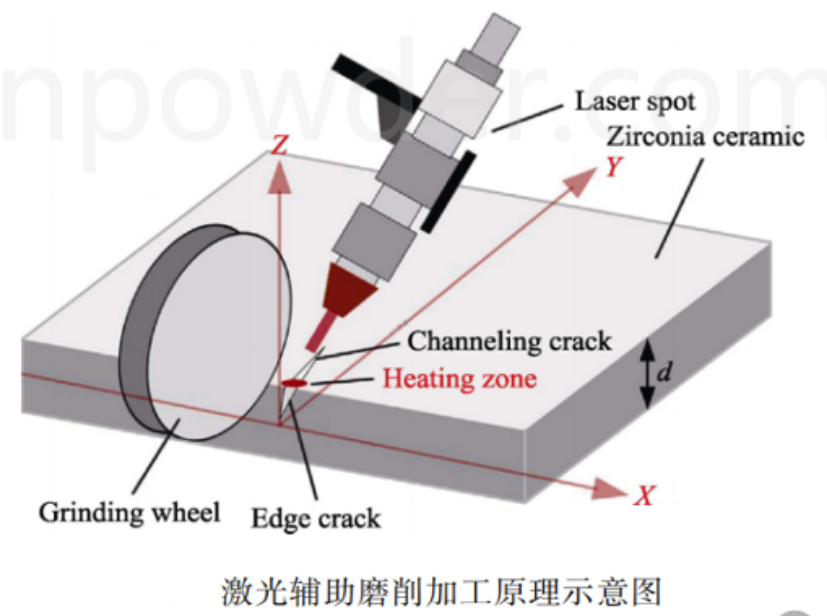

Laser-assisted grinding technology

Laser-assisted grinding technology is mainly used to solve the problem of low cutting efficiency and easy cracking of hard and brittle materials. It has been widely used in the grinding processing of technical ceramics such as zirconia, silicon carbide and silicon nitride.

Precision and ultra-precision grinding

Grinding generally economically produces parts with a surface roughness Ra value between 0.20 and 2.00 μm. However, with the continuous development of science and technology and the increasingly higher requirements for machining precision and surface integrity, grinding has become a major problem in modern equipment manufacturing. It is the most effective and widespread practical technology for achieving precision and ultra-precision machining. Many parts are suitable for precision grinding (Ra value is 0.025 ~ 0.250um) and ultra-precision cutting (Ra value is less than 0.025). μm) are also increasingly in demand, which is why modern grinding technology is moving in the direction of miniaturization.

Low surface roughness grinding

In engineering, ordinary abrasive wheels are mainly used for low surface roughness grinding of iron-based materials (Ra value less than 0.2 μm). Based on the characteristics of ordinary materials whose hardness is lower than diamond, more fragile and easy to cut, sharp diamond tools are used, and fine cutting is used to give the surface abrasive grains of the grinding wheel a micro- edge and outline. The micro-cutting effect of the abrasive grains on the surface of the grinding wheel, the microplastic flow of the metal material, and the extrusion, friction and polishing effects between the two make the texture of the grinding surface extremely fine and smooth .

At present, low surface roughness grinding is widely used to process machine tool spindles: raceways, ball rollers, guide rails, hydraulic parts and other precision parts. The application is relatively popular.

ELID grinding

ELID grinding has expanded the application range of ultra-fine grain (600#~30000#) metal-bonded grinding wheels and superabrasive grinding wheels, and is particularly suitable for precision and ultra-precision grinding of hard and brittle. It has been used successfully in ceramics. reflectors, aspherical glass lenses, ferrite devices, raceways and mold processing.

ELID grinding has high efficiency, high precision and good quality. However, due to the limited space for installing the ELID device on the existing bed and the high requirements for electrolyte maintenance, its application range is not large, and it is mainly used precisely . processing areas such as optics, electronics and instrumentation.

Grinding of the ductile domain of fragile materials

At present, semi-ductile domain grinding is widely used in engineering, and the material removal methods include both brittle fracture and plastic deformation. Due to the large number of abrasive grains on the surface of the grinding wheel, the height of the abrasive grains varies, and the cutting depth of the abrasive grains can be high or low. During each grinding operation, certain abrasive grains have a thickness. cutting depth at the nanometer level, that is, the grinding of the ductile domain is always accompanied by hard and brittle materials during the grinding process;

In addition, with the reduction of the particle size of the grinding wheel, the improvement of the balancing precision of the grinding wheel, the refinement of dressing precision, the improvement of rigidity, precision and dynamic characteristics of the grinding machine, especially the refinement of the feeding mechanism of the grinding machine, the grinding of hard and brittle materials in the ductile field will inevitably become more difficult. The proportion of cuts will increase. At present, the ductile field grinding of hard and brittle materials is mainly used in the fields of electronic information, aerospace and ceramic bearings, and the application scope is relatively narrow.

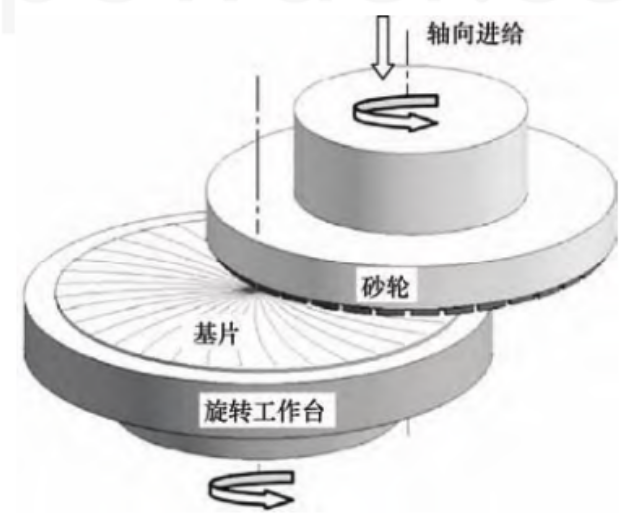

Self-rotating grinding of the workpiece

Rotational workpiece grinding technology was proposed by Japanese researcher Matsui S in 1988 and is currently the mainstream in silicon wafer thinning and grinding. The silicon wafer is clamped using a vacuum suction cup, and a cup-shaped diamond grinding wheel is used for one-to-one end grinding. The outer circle of the grinding wheel is aligned with the center of the silicon wafer. the silicon wafer and the grinding wheel each rotate about their axes, and the grinding wheel is fed along its axial direction.

CMP

In the ultra-precision processing of wafers, in order to achieve damage-free, smooth and high-precision surface, researchers have proposed many processing methods, including: magnetic levitation polishing, electrophoretic polishing, float polishing , elastic emission polishing, magnetorheological polishing, ion polishing, etc. Beam polishing, shear thickening polishing, hydrated polishing, chemical-mechanical polishing, etc. Among them, chemical mechanical polishing (CMP) is the most widely used.

CMP is where the rotating part contacts the rotating polishing pad under a certain pressure and polishing fluid. Through the synergy of the grinding effect of micro-nano scale abrasive particles and the chemical corrosion of oxidants, a high level. a quality, damage-free surface can be quickly achieved.

CMP appeared with the development of semiconductor industry and is currently mainly used in single crystal silicon, polycrystalline silicon, sapphire, silicon oxide, silicon carbide, quartz crystal, copper , tungsten, etc.

CMP is a comprehensive processing technology that integrates mechanics, tribology, materials science, mechanics and chemistry. It avoids the defects of simple mechanical polishing, prone to surface damage, and simple chemical polishing, such as slow speed, poor flatness and poor surface consistency. its processing capacity and speed simultaneously meet the processing requirements of the wafer.

Belt grinding

Abrasive belt grinding uses a coated abrasive tool (abrasive belt) as a tool, supplemented by a contact wheel or pressure grinding plate to increase the rigidity of the abrasive tool and maintain the abrasive belt in a tensioned and functional state to treat the surface. of the workpiece.

Abrasive belt grinding is essentially different from wheel grinding. Its main characteristics are as follows:

1) The abrasive belt is fine and tough, has good adaptability, and can be processed with corresponding contact methods according to the shape of the workpiece;

2) The grinding surface has good integrity, the abrasive belt is fine and the curvature is constantly changing, it has good vibration absorption, fast heat dissipation, is not easy to block, the grinding temperature is low and the grinding quality is good;

3) The grinding efficiency is high, the grinding speed of the abrasive belt is constant, and the width can generally be customized according to the grinding surface of the workpiece, with the maximum width reaching 5m, high efficiency and low cost;

4) High grinding ratio and low energy consumption. Abrasive belt grinding generally operates at low speeds. The abrasive grains on the abrasive belt have stronger cutting ability than the abrasive grains on the grinding wheel. that of grinding the millstone;

5) It can grind various materials, not only metal materials, but also non-metallic materials such as wood, plastic and leather. It also has good processability.

Smart grinding

Intelligent grinding is a new upgrade of CNC technology. It uses advanced sensor technology and data processing methods to realize perception, prediction and control of the grinding process to achieve the goal of cost-effectively improving precision and surface quality.

Grinding is an extremely complex multifactorial interactive system. Only comprehensive intelligent grinding which achieves multi-sensor monitoring, multi-parameter tracking, multi-signal fusion analysis and comprehensive evaluation is an important direction for the development of modern grinding engineering and grinding. technology. . There is still a long way to go for the application of multiparametric intelligent grinding engineering.

green grinding

Traditional grinding uses a large amount of grinding fluid and uses pouring to cool the temperature of the grinding zone. Extensive use of grinding fluid causes certain harm to the on-site environment and the health of operators, and increases the company’s grinding processing costs. Facing the sustainable development needs of human society, green grinding technology is a modern manufacturing model based on the concept of green manufacturing and comprehensively considering the two major issues of environment and resources from the perspective of ecology and economics.

At present, the research topics mainly include internal cooling grinding, low temperature cold air grinding, high pressure jet grinding, atomized cooling grinding, minimum lubrication grinding, grinding with solid lubrication and dry grinding.

dry grinding

Dry grinding eliminates the hazards caused by grinding fluid because it does not use grinding fluid. However, at the same time, problems such as deterioration of the grinding environment, workpiece burnout and reduced life of grinding wheels limit its application in the production process.

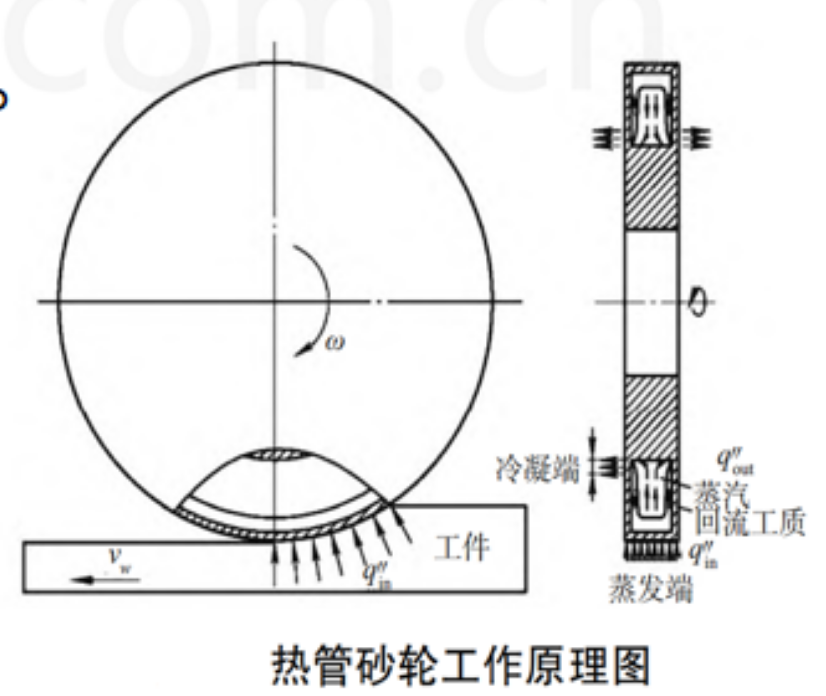

Grinding heat is a key factor limiting its application. Methods such as ultrasonic vibration, heat pipe heat exchange and the development of self-lubricating grinding wheels have been adopted to reduce grinding heat and improve processing performance, but their practical application requires in-depth research.

Minimum quantity lubrication technology

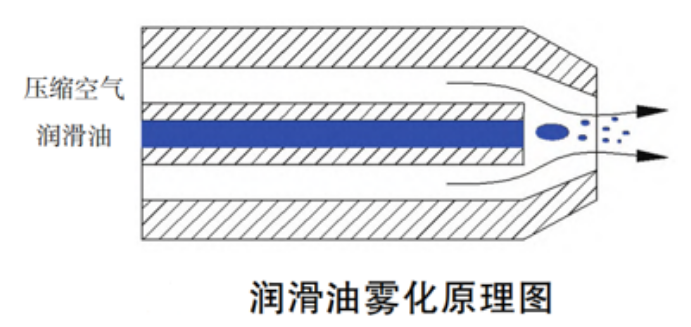

Minimum quantity lubrication (MQL) technology mixes a small amount of lubricating oil with compressed air, atomizes it and sprays it into the treatment area as an aerosol. This allows the grinding fluid to pass through the air barrier layer and cool and cool effectively. lubricate the grinding area.

At present, the research focus on this technology is to improve the atomization performance of MQL, prepare suitable atomization media, and combine MQL with other cooling and lubrication methods. .

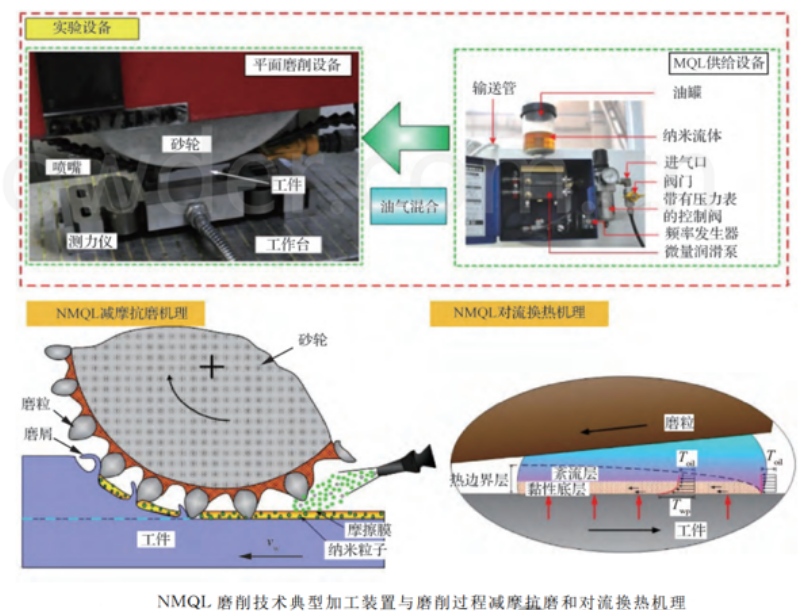

To fully meet the heat transfer needs of grinding, researchers proposed a more efficient nanofluid minimum quantity lubrication technology (NMQL), i.e. a certain proportion of nanosized particles is added to the minimum amount of lubricant and both are added. fully mixed. The nanofluid is prepared, atomized by compressed gas and transported to the grinding zone.

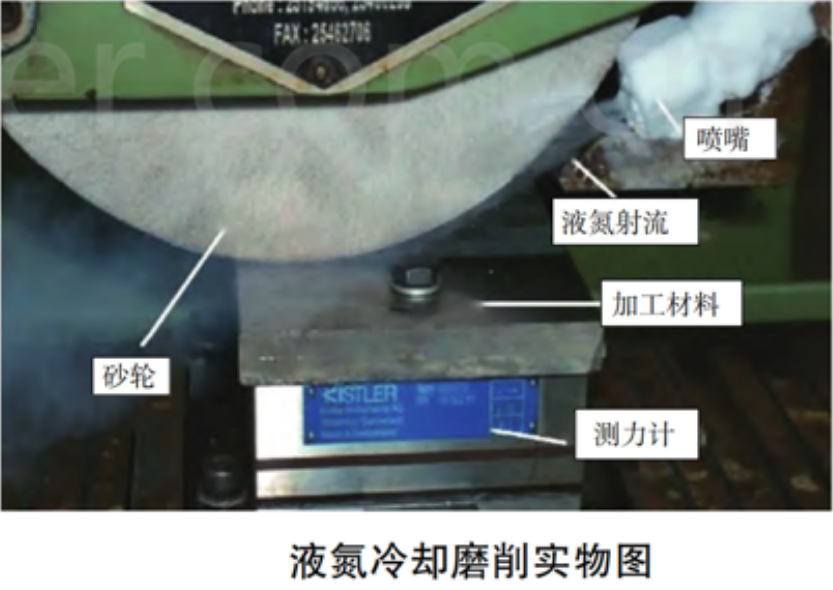

Grinding by liquid nitrogen cooling

Liquid nitrogen cooling grinding is a processing method in which liquid nitrogen is sprayed into the processing area as a cooling medium to cool the workpiece and tools.

Liquid nitrogen grinding has strong cooling capacity and can solve the grinding of difficult-to-machine materials. However, its economic cost is high and it is not conducive to promotion. Using liquid nitrogen for processing will make the environment humid and easily rust the machine tool.

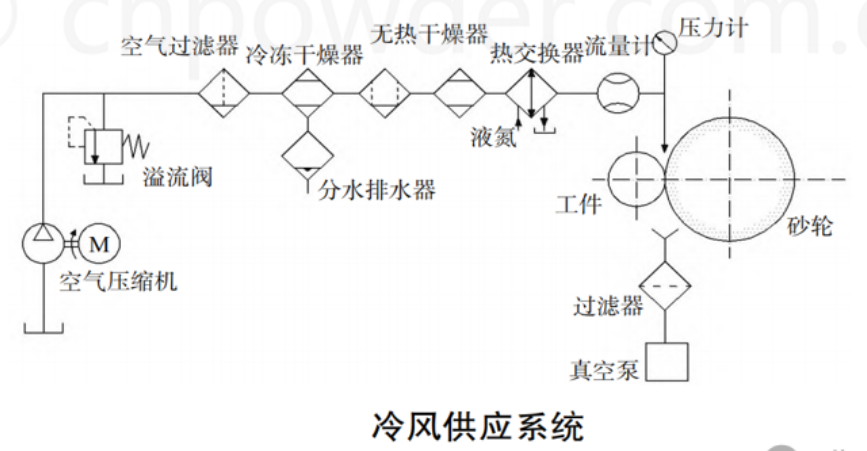

Low temperature cold air grinding

The coolant for low temperature cold air grinding is common air and does not require additional storage. However, its cold air supply system is more complex and the equipment is noisier. Low temperature cold air has insufficient lubrication performance and is only suitable for grinding with small cutting depth.

solid lubrication technology

Solid lubrication technology is a lubrication technology that adds solid fluid as a lubricant to the friction contact surface to reduce friction and wear. Commonly used solid lubricating materials include graphite, molybdenum disulfide, calcium fluoride, etc. This type of material has a layered structure, low shear strength and easily adheres to the surface of the part. It is very suitable for lubricating the grinding surface.

Its excellent friction reduction, wear resistance, broad temperature characteristics and speed of execution brought it to early use in the lubrication field.

How to make the solid lubricant effectively penetrate into the grinding area and form a stable lubricating film layer is a key issue that affects the lubrication effect.

3. Existing problems and suggestions

Advanced grinding technologies such as super hard abrasive grinding, fast and efficient grinding, precision and ultra-precision grinding, abrasive belt grinding, intelligent grinding, green grinding, etc. are characterized by high speed, high efficiency, longevity, precision, flexibility, green, etc. It has obvious advantages and is more in line with the “Made in China 2025” development strategy. It has good development prospects and deserves vigorous promotion.

There are problems with domestic advanced grinding technology

High-end ultra-hard abrasives are mainly monopolized by foreign countries

Since there is no hardness standard for domestic ultra-hard abrasives, there is still a considerable gap between their serialization, standardization, stability, reliability, etc. and foreign brand products.

Taking the application of medium and high-end superabrasives in automobiles, semiconductors, tools, bearings, etc. as an example, domestic grinding wheels only account for about 20%, while high-end superabrasives are still mainly monopolized by foreign products. superabrasive grinding has entered the development stage. During the bottleneck period, it is difficult for domestic super-hard grinding wheels to enter the high-end abrasive market.

Domestic high-end grinding equipment engineering application limited

High-end grinding equipment is the basis for promoting advanced grinding technology. After decades of development, my country’s manufacturing industry has made great progress and development. My country is currently the country with the most comprehensive manufacturing categories and the largest production of machine tools in the world. However, our country’s CNC grinding machines are still dominated by the middle to low-end market. The field of high-end grinding machines, key components and key equipment are still dependent on imports and are not yet fully self-reliant. -sufficient.

For inquiries on imported high-end grinders: 135 2207 9385.

There is a serious gap between academic research on grinding technology and technical applications.

The grinding wheel is a multi-element, porous and non-homogeneous composite material. Its surface has many abrasive grains, different shapes, different heights, limited chip tolerance and a large negative rake angle at the edge. The application of grinding wheels is different from general mechanical engineering. The influencing factors are extremely complex and there are countless uncertainties. Therefore, research into grinding technology must be based on technical applications and rely on large amounts of data from experiments and statistics.

However, over the past two decades, there has been a serious gap between domestic academic research and technical applications in this field. Many engineering topics cannot be realized, and a large number of academic papers are modeled, simulated and published. under countless assumptions, which leads to certain problems. Strange results and phenomena without application even seriously deviate from technical reality and make no sense for grinding applications.

Development proposals

Grinding is a complex system engineering, and China still lags behind developed countries in the application of advanced grinding technologies. In order to improve the application of comprehensive grinding technology in China, multi-dimensional collaborative cooperation among grinding equipment, functional components, grinding wheel manufacturers and users, and universities is necessary. Not only should basic academic research be carried out, but also should focus on key common technologies and technical application research, and a comprehensive integrated research mechanism should be established, which will help to rapidly expand the scope of research. application of national advanced grinding technology.

Whether it is difficult-to-machine metal materials, hard and brittle materials, or composite materials, reducing the grinding force and grinding temperature will help improve the surface integrity of the workpiece and reduce grinding wheel wear, the basic strategy to improve grinding of difficult materials; The materials to be machined are nothing but reduction. The elastic-plastic deformation of the workpiece material during the grinding process reduces the friction between the abrasive particles and the workpiece and reduces the force and heat transmitted to the workpiece and the grinding wheel.

The effective processing methods for improving the grindability of difficult-to-machine materials can be summarized as follows: improve the grinding ability and heat dissipation capacity of the grinding wheel by using very hard abrasive grains, improve the structure of the grinding wheel, and arrange abrasive grains in an orderly manner. and using a low temperature medium to force replacement to reduce the grinding temperature; through the composition of multi-energy fields, the strength and hardness of the material layer to be crushed are weakened, making it easy to remove; Fast grinding methods, the grinding force and grinding temperature are reduced, thereby improving grinding efficiency and reducing the damage caused by grinding.

Reference sources

1. Feng Keming et al. Application status and outlook of advanced grinding technology

2. Lu Shouqiang. Research advances on the grindability of high-performance, difficult-to-machine materials.

3. Guo Dongming et al. Research status and development trends of ultra-precision grinding technology for semiconductor substrates

4. Ding Wenfeng et al. Research status and outlook on titanium material grinding technology for aerospace engines.

5. Ding Wenfeng et al. Current status and research prospects of ultrasonic vibration-assisted grinding processing technologies and equipment.

6. Cai Zhongwei et al. Research Progress on Ecological Grinding Processing Technology

7. Jintan et al. Development of high-performance grinding technology that challenges the extreme and its application prospects in the field of aircraft manufacturing

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.