In March 2023, the world’s first 3D printed rocket made its third launch attempt. Unfortunately, it did not enter the intended orbit when the second stage was ignited. This isn’t the first time 3D printing technology has been used to help with rocket designs. Previously, at the end of 2022, another 3D printed rocket booster successfully completed preliminary testing. The booster had adopted an internal regenerative cooling design strategy. The new GRCop-42 copper alloy once again demonstrates the ability of additive manufacturing to accelerate R&D innovation in the industry.

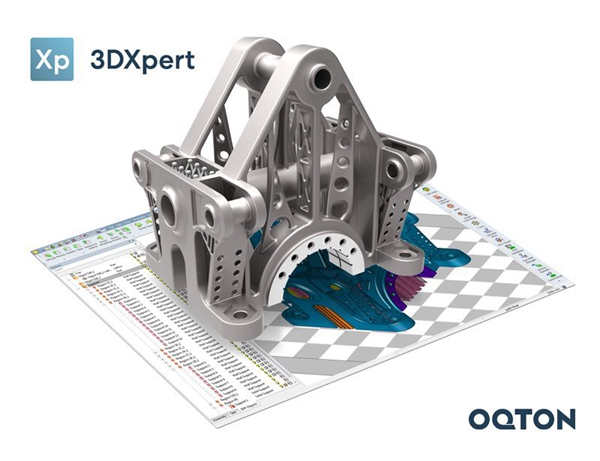

△3DXpert will help 3D print rocket boosters in late 2022

The use of regenerative cooling design strategies can be used to regulate the temperature of the rocket fuel as it flows through the cooling lines, thereby removing more heat from the propellant sidewalls before it returns to the chamber for combustion. 3DXpert played a key role in developing optimized print settings and preparing print files for this project’s rocket booster.

Optimizing Rocket Thrusters Using 3DXpert

Project managers Evan Kuester, Ryan Fishel, and Cameron Schmidt used Oqton’s 3DXpert to develop print settings and prepare print files, including part placement, support design, parametric tests and data cutting.

“The most innovative aspect of this thruster is the choice of material, which uses a newly developed copper alloy and is produced by 3D printing. 3D printing reduces the time required for manufacturing compared to traditional manufacturing methods” , explained Schmidt. , senior application development engineer.

“Additionally, as a copper alloy recently developed by NASA, GRCop-42 has properties well-suited for high-temperature applications and can be used in parts such as rocket boosters. By combining this with laser powder bed fusion technology, we achieved the goal in a relatively short time. This propeller is manufactured in-house and has good density and mechanical properties,” he added.

Innovation and expansion of additive manufacturing

This rocket booster is a new addition to the application area of 3D printed rockets, which has been growing steadily in recent years. Today, many startups are developing 3D printers capable of manufacturing rocket components. While 3D printed rockets have attracted a lot of attention, they represent only the tip of the iceberg in aerospace applications. Additive manufacturing can realize the production of similar parts at one time, saving time and costs, and greatly promoting the application of additive manufacturing in related industries.

Manufacturing complex devices with multiple components presents many technical challenges. Each component must be manufactured and assembled individually, a long and tedious process. 3D printing changes this, enabling the integrated design and printing of complex devices, making the development and manufacturing of final products faster and less expensive.

Regeneratively cooled rocket nozzles, such as rocket boosters printed with new copper alloys, have been made using traditional manufacturing methods for decades. Manufacturing rocket boosters of this size would normally take months, but the 3D printed boosters were created in just a few weeks.

The shorter lead times associated with additive manufacturing have huge implications. First, rapid iteration helps reduce costs, and second, manufacturers can accelerate the pace of innovation. Because parts can be produced faster, engineers using 3D printing can conduct more experiments and test various designs before choosing the best solution, without incurring excessive costs.

3DXpert enables additive manufacturing and opens up unlimited possibilities

“For traditional manufacturing, although engineers can design different solutions, due to the cost and long delivery times, exploring different designs will require a huge amount of energy and resources. After using 3D printing, if the effect is not good, you can go back to design and modify quickly,” says Schmidt.

Additionally, with additive manufacturing technology, designs can be improved and optimized to create geometries not possible using traditional methods. 3D printing can improve part performance using complex geometric surface arrays, topology optimization, etc., which is difficult or impossible to achieve with traditional processes. These design principles have already found impressive applications in heat exchangers, medical implants and structural scaffolding. Like the thruster cooling channel mentioned above, it is fully integrated into the sidewall and runs through the entire thruster. It can be distributed in almost any way to further optimize heat conduction.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.