The Art of Grinding: A Comprehensive Guide to Achieving Precision and Surface Quality

In the realm of industrial production, grinding is a vital step in ensuring the precision of surfaces and roughness of rooms. This intricate process involves a series of techniques, ranging from coarse grinding to polishing, each tailored to meet specific product requirements and production stages. In this article, we will delve into the world of grinding, exploring its various processes, characteristics, and corresponding wheel selection guidelines.

Understanding the Grinding Processes

Grinding can be broadly classified into four stages: coarse grinding, semi-fine grinding, fine grinding, and polishing. Each stage has distinct objectives, characteristics, and wheel selection requirements.

- Coarse Grinding

- Objective: Quickly remove a large amount of material from the surface of the room, thereby bringing it close to its final shape and size.

- Characteristics: High grinding efficiency, but the treatment surface is relatively rough. A significant amount of heat and fines are generated during the grinding process, which necessitates the use of grinding wheels with good wear resistance and chip elimination.

- Wheel Selection: Coarse grain size, slightly soft hardness to improve grinding efficiency and adapt to wear during grinding.

- Semi-Fine Grinding

- Objective: Remove the remaining material from the surface, improving the roughness of the surface while preparing it for grinding or final polishing.

- Characteristics: Slightly lower grinding efficiency, but the quality of the treatment surface has improved. The grinding wheel should have good auto-sharpenness and resistance to wear.

- Wheel Selection: Medium grain size, average hardness to balance grinding efficiency and surface quality.

- Fine Grinding

- Objective: Achieve high-precision treated surface values and low roughness values.

- Characteristics: The lowest grinding efficiency, but the quality of the treatment surface is highest. The grinding wheel should have delicate abrasives, good auto-sharpenness, and resistance to wear.

- Wheel Selection: Fine grain size, slightly hard hardness for better surface quality and precision.

- Polishing (Optional)

- Objective: Improve the brilliance and roughness of the surface, achieving the mirror effect.

- Characteristics: Polishing is a fine processing step that requires the use of specialized polishing tools and materials.

- Wheel Selection: Polishing materials, such as polishing fabric, polishing paste, or polishing liquid, must be selected according to the material and part of the product.

Precautions for Selecting Grinding Wheels

When choosing grinding wheels, several factors must be considered to ensure optimal performance and sustainability:

- Part and Hardness Material: The material and hardness of the part must be taken into account to ensure the grinding wheel meets the necessary requirements.

- Surface Grinding and Roughness Efficiency: Balancing grinding efficiency and surface roughness requires selecting the appropriate grain size and hardness of the grinding wheel.

- Furniture and Size of the Grinding Wheel: The grinding wheel’s shape and size must be selected to accommodate the equipment and treatment needs.

- Cost and Budget: The initial investment in a high-quality grinding wheel may be higher, but it tends to have a longer lifespan and better quality of treatment, making it more economical in the long term.

Special Product Processing Requirements

Some products require specialized processing, such as:

- Cross Grinding Only: Certain products require only a large amount of material removal, making coarse grinding the only option. Choose effective coarse grinding wheels and wear-resistant materials to improve treatment efficiency.

- Multiple Processes: Products requiring high precision and low roughness may necessitate more than three stages of grinding. Combine coarse, semi-fine, and fine grinding with polishing to achieve the desired quality and surface accuracy.

- Products Requiring Polishing: Products requiring mirror effects necessitate polishing after fine grinding. Select the appropriate polishing material and process settings for optimal polishing results.

Conclusion

Grinding is a complex and intricate process that demands careful consideration of various factors to achieve optimal results. By understanding the objective, characteristics, and requirements of each grinding process, practitioners can formulate reasonable processing plans and select the right grinding wheels to meet specific product needs. Furthermore, special product processing requirements must be taken into account to ensure the best possible outcomes. With this comprehensive guide, practitioners can navigate the world of grinding with confidence and precision.

Layout:

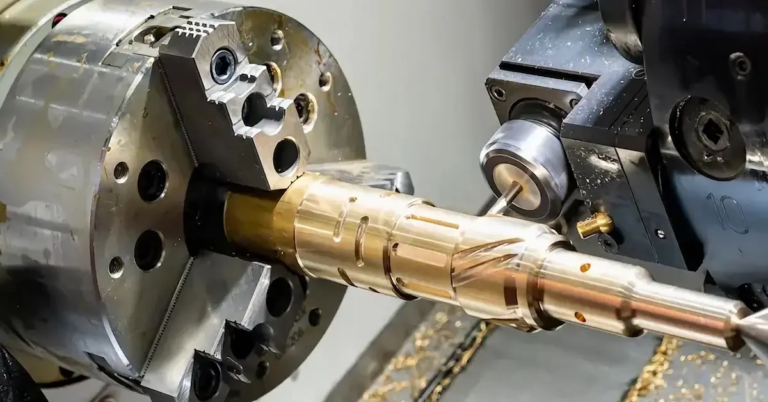

- Hero image: A high-quality image of a grinding process or a product with a well-finished surface.

- Main content:

- Introduction: A brief overview of the importance of grinding in industrial production.

- Understanding the grinding processes: A detailed description of the four stages of grinding, including their objectives, characteristics, and wheel selection requirements.

- Precautions for selecting grinding wheels: A list of factors to consider when choosing grinding wheels, including part and hardness material, surface grinding and roughness efficiency, furniture and size of the grinding wheel, and cost and budget.

- Special product processing requirements: A discussion of the unique processing needs of certain products, including cross grinding only, multiple processes, and products requiring polishing.

- Conclusion: A summary of the main points and the importance of careful planning and selection in the grinding process.

- Call-to-action: A suggestion to readers to explore the various options and considerations in the grinding process.

- Additional resources: A list of additional resources for those interested in learning more about grinding and its applications.