Resin3DPrinting is not a simple process, with3D FDMDifferent printing technologies often require a large number of post-processing steps to obtain real prints. Generally speaking, to clean the resin3DPrinted parts typically require a density of 90% or higher isopropyl alcohol (API). However, the concentration of API The costs will be high. To solve this problem, materials engineers developed water-washable resin, a special new type of resin that can be cleaned effectively using water as a solvent without the need to process large volumes. API or other solvents.

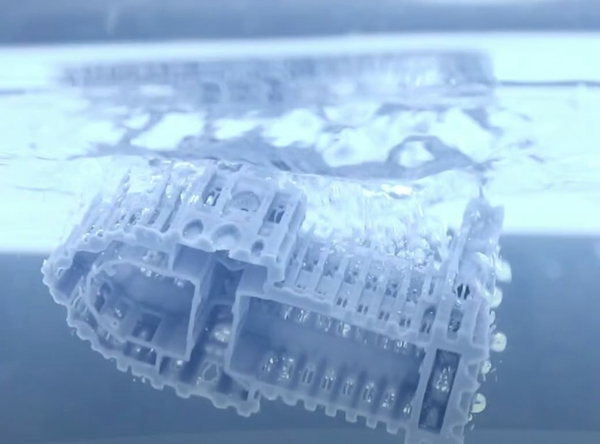

△Can you tell if these were printed with standard resin or washed resin?

the difference

What are water washable resins and how do they compare to standard resins? Depending on the brand, resins can vary considerably:

●Standard resin is any resin that does not have special properties (i.e. flexible, biomedical or castable). 3D Printing resin should be cleaned in isopropyl alcohol or other organic solvents after printing. These are today’s desktops3DMost commonly used in the printing market3Dprinting resin, almost all3DPrinting resin suppliers will sell standard resins.

●Water-washable resin is a more recent innovation. Users only need to soak the resin printed parts in water or low concentration. API you can remove the excess resin. This resin is 2016 Invented in 2001, but has since been widely used in desktop resin 3D Print.

The most significant difference is in the type of solvent required for print post-processing, but other differences are also found in the characteristics of the finished part.

△Water-washable resin cannot be washed in the sink (source:Reddit on nycrayline)

Resin formulations can vary significantly between resin manufacturers, even within the same resin type. Therefore, it is difficult to make statements about general differences in material properties between water-washed resins and standard resins. However, this does not mean that the material properties of the resins are the same. Within the same brand, water washed resins and standard resins will have different properties due to different chemical compositions, which can affect tensile strength, flex modulus and available colors. For example,Anycubic The tensile strengths of standard and water washable resins are respectively 36-45 And 30-45 MPa。Anycubic Water washable resin has a higher flex modulus range and is stiffer than standard resins.

Printing and post-processing

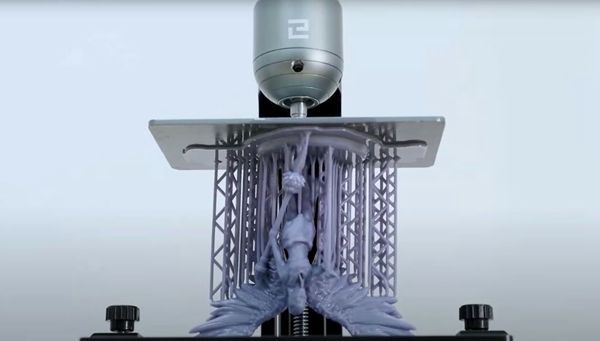

△The printing process is consistent

Water washable resins and standard resins can print exactly the same. Standard resins and water washable resins print on the same model.3DPrinters may have similar layer cure times. As mentioned above, the biggest difference is that the print changes from 3D Cleaning process that occurs after removing the printing plate from a printer. Depending on the brand, washable resin 3D The print is immersed in 0-10% IPA in aqueous solution. Some brands of resin only require a little APIwhile other brands of resin are truly washable and do not require API This will remove any remaining liquid resin. For standard resins, post-processing solvents include 90-99.9% isopropyl alcohol. Regardless of the type of resin, cleaning times are specified by the manufacturer.

Solvent treatment

Regarding solvent treatment, please note that clean water containing uncured resin cannot be poured down the drain! it must look second hand API Treat it the same way, place it in the sun, wait for it to evaporate and leave resin residue, then throw it away. Another option is to dispose of contaminated water according to local hazardous waste regulations in your area.

price

△Color options for water washable resins are sometimes limited compared to standard resins

Water washable resins are generally slightly more expensive than standard resins from the same resin manufacturer. In addition, washable resins are often available in different colors than standard resins, sometimes even less. For example,Sunlu The standard price of resin is approximately per kilogram 27 USD, available in eight colors; washable resin sells for approx. 31 dollars and only 5 colors available. in addition Anycubic products, their standard resin sells for approximately 20 USD, available in seven colors, while their washed resin sells 34 USD, and only six colors are available.

△Be careful of cracks!

Notice

Water washable resins will eliminate the hassle of purchasing, damaging and disposing of more expensive organic solvents. If you’re a hobbyist, washable resin is definitely a useful material, as the prints can be rinsed under your home’s faucet. However, washable items are very sensitive to humidity and water damage, so special attention should be paid to them.

Additionally, one of the disadvantages of water washed resins and standard resins is that they are both fragile, with water washed resins being slightly more brittle than standard resins. When the applied stress exceeds the yield strength of the cured resin, the part cracks like glass. There is also a risk of residual resin in hollow prints, which can cause cracking during the post-curing process.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.