China is the largest ball pen in the world. The tip of the ballpoint pen is made up of pearls and the body of pearls. Make sure that the body of the ball depend on the importation of the foreigner. In order to solve the problem of the stuck neck of the ball pen, China has developed a domestic pen treatment machine and a steel plant.

In terms of pens processing machine tools, due to the difficulty of monitoring the pearl pen, there is a high technical threshold for the treatment of machine tools. Although the size is small, although the size is very small, the internal structure is very complicated. The precision of treatment of the stand body is extremely high. In addition, the manufacture of the carrier must go through more than ten processing processes, and the multi-fitting pen-and pen-treatment machine tools at high speed can meet the needs of high efficiency machining of the machining body.

In the past, there were only two companies that produced multi-site pen tools, namely Mi Kerang in Switzerland and struck in Germany. The machine tools are at 4.5 million.

To this end, the Zhencai stationery has developed a domestic multi-treatment processing machine tool. Material. The tool-tool adopts rotary gas suspension discs and dynamic balance systems to guarantee the maintenance of high precision in high-speed operation. The machine tool is also equipped with a rotary domestic engine of 60,000 to improve production efficiency. The cost of this machine tool is approximately 1.5 million, which can reduce the cost of production of the round pearl pen.

Currently, the multiple electronic email machine at the Zhencai stationery has been exported to Malaysia, India and other countries. In addition, the machine can also be used in industries such as mobile phones, cars, clocks, electronics, etc., adapted to many industries with high requirements for parts and high production demand for The parts.

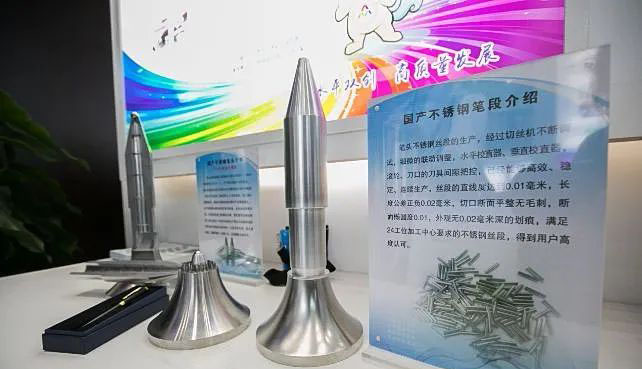

In terms of Nibuki Steel, two Chinese companies can produce steels at the forefront of the pen. Due to the severe requirements of the carrier’s body, feather steel as the material of the siege body must also meet various requirements. Due to the small body size, the complex internal structure and high treatment precision requirements, steel must have a good easy and easy -to -treat cut. At the same time, it is necessary to ensure that steel does not crack during treatment. In addition, ink is corrosive and friction occurs during writing. Consequently, steel from the tip of the pen must have good resistance to corrosion and resistance to abrasion. In order to meet various performance requirements, steel must be added with various trace elements.

Tai Gang Group lasted five years. Subsequently, the point of the imported pen of the imported pen went from 120,000 yuan per tonne to 90,000 yuan. In addition, the Tai Igang group used 替 instead of lead and has developed a more environmentally friendly penalty steel.

After that, the Qingtuo group also produced a tribal steel with a diameter of 2.3 mm. The Qingtuo group has also developed tribal steel with a diameter of 1.6 mm. The Qingtuo group has also creatively replaced lead and PUPES by TIN as an easy -to -cut element to produce steel of environmentally friendly pen tension. In addition, under the premise of ensuring resistance to corrosion, the content of the Molybdene group in steel of the pen of the Qingtuo group is 50% lower than that of the pins of other societies, which considerably reduces costs.

Chinese steel companies have not only changed the history of steel to pins that can only be imported from Japan, Sweden and other countries, but also permanently improved the competitiveness of the tension of the Chinese pen thanks to active innovation.

Conclusion

Chinese machine-to-processing and sment-tone-to-pen steel machines can considerably reduce production costs of companies made to a pen, which is very important for large countries. In addition to the pen industry, the pen-processing machine can also be used for other industries. In addition, the pen slope is a breathtaking type of steel. China has solved the problem of round pearl pen cards and the results can be applied to other areas.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.