Wärtsilä Senior Marine Additive Manufacturing SpecialistWhen Francesco Trevisan decided to design the perfect cylinder head for a marine engine, he chose to use metal 3D printing technology to design it to make it lighter and more efficient. The technique allows him to create complex lattice structures, material-saving organic shapes and integrate multi-part components into a single unit.

After a lot of design work and virtual simulations, it’s almost perfect. It is lighter than the original model manufactured in the traditional way60%. It integrates up to ten subsystems into the final assembly, reducing assembly complexity and improving cooling performance. This is an innovative design that will contribute to Wärtsilä’s goals of carbon-neutral shipping and energy production,

butIt’s simply not possible.

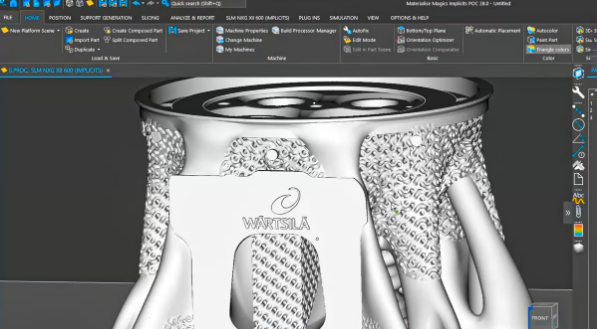

WartsilanTop cylinder head design (Source: nTop)

The obstacle is not design integrity, nor fusion on a large bed of laser powder.3D printer performance. It’s not metal powder eitherbutThe problem is the file size of the digital parts.

But now software companiesA new collaboration between nTop and Materialize Magics provides a solution that reduces part file sizes by approximately 90%. This development will not only allow Wärtsilä to produce its large cylinder heads, but could also accelerate the adoption of metal 3D printing in almost all industries.

Design Bottlenecks in Complex Metal Additive Manufacturing

Wärtsilä plans to use Nikon SLM laser powder bed fusion 3D printers, such as this 600E version, to 3D print its marine engine cylinder heads (Source: Nikon SLM)

Previously,Trevisan’s complex engine component or heat exchanger designs result in computer-aided design (CAD) files ranging in size from 7 to 10 GB. Feature-rich CAD models , such as extremely fine meshes, extend the capabilities of current software, with file sizes and reconstruction times increasing exponentially as part sizes increase.

However, this size is approx.The 500 x 500 x 450mm marine engine cylinder head was optimized for 3D printing in nTop’s ‘computational design’ software, allowing Trevisan to add highly intricate details such as trusses and internal channels, and merge individual parts into a single part without the need for multiple gigabyte files. nTop is similar to CAD software, but it is more sophisticated in the way it represents part geometry and the file size is much smaller.

For example, in mostIn CAD programs (including Fusion and Creo), part geometry is represented using “boundary representations” (B-reps). We won’t go into all the complexities of B-rep architecture here, but let’s think of it as how humans perceive geometric shapes, edges, measurements, and their relationships to each other. When parts become very complex, they can take up a lot of computer resources and file space.

As the demand for complex geometries, topology optimization and generative design continues to grow, especiallyWith the rise of additive manufacturing in the early 21st century, CAD file size began to become an issue. Around this time, as computing power increased and became available, a new method of representing geometry in CAD software, called implicit modeling, began to gain traction.

The power of implicit modeling

The implicit modeling used by the nTop software is an alternative way of representing the geometry of parts. It does not explicitly calculate any edges or vertices, but uses a single mathematical function of x, y and z to describe a 3D entity. In other words, a geometric shape is represented by mathematics that defines whether a point is located inside, outside, or on the surface of the shape. Bradley Rothenberger, CEO of nTop, said it’s more like a computer view of geometry.

Implicit modeling excels at blending or merging complex geometries without manually defining transitions or boundaries, making it particularly useful for organic shapes and designs requiring complex surfaces.

The resulting file size may be smaller than normal.One-tenth the size of CAD files, but just as precise.

existIn nTop, Trevisan now has a cylinder head file, but it cannot be 3D printed directly from nTop’s .implicit files; they must be converted back to a more familiar mesh-based B-rep model to be entered into the 3D printing file preparation software; Materialize yourself in magic. This is where the project faces a significant obstacle.

The Gridless Future of CAD

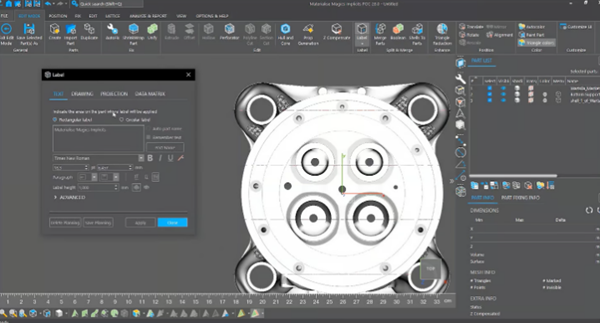

Wärsilä cylinder head in the Materialize Magics file preparation software (Source: Materialize)

The resulting mesh file is too large and difficult to print.

“The bottleneck in Wärtsilä is becoming tangled,” says Rothenberg. “They couldn’t mesh the room efficiently because it would take hours to mesh it in nTop, and once meshed it would take hours or even nights to open it in Magic, then weeks. It takes time to cut pieces to the size of a cylinder head.

Trevisan said there was a good chance the system could crash at any stage of transferring or processing files, which would mean starting over and causing weeks of delays. In the past, his solutions included splitting the mesh or splitting the design into multiple parts. “There is always a need for compromise,” he said. “We were limited in the level of mesh detail, so the detail quality of the final print often suffered. »

He needs a way to.implicit files are imported directly into Magics from nTop, a feature nTop just announced in August.

“One of the coolest aspects of the integration with Magics is allowing customers to 3D print directly from .implicit files,” Rothenberg said. “As an implicit file, exporting a cylinder head from nTop takes only seconds, opening in Magic takes only minutes, and slicing takes only a few hours.”

The nTop implicit modeling API in the Materialize Magics 3D printing suite (which will be available with the next release of Materialize Magics in 2025) eliminates implicit conversion to mesh, which is a huge obstacle for large metal parts.

existWärtsilä cylinder head in Materialize Magics file preparation software before printing on the SLM NXG 600 3D printer (Source: Materialize)

so far,Magics isn’t nTop’s only integration. It announced the launch of a plugin for EOS 3D printers compatible with the EOSPrint 2.14 build process of the 2023 machine. This essentially achieves the same functionality as the Magics integration, but only for machines of 2023. EOS brand.

“After Magics, there are other plugins and CPU integrations under development,” said Daeho Hong, nTop senior product manager responsible for building the implicit ecosystem with partners.

nTop isn’t the only software company to offer implicit modeling – a few offer this feature in Siemens NX and Altair Inspire – but it is the most advanced to date, which begs the question: CAD modeling is it the future of CAD?

Is implicit modeling the future?

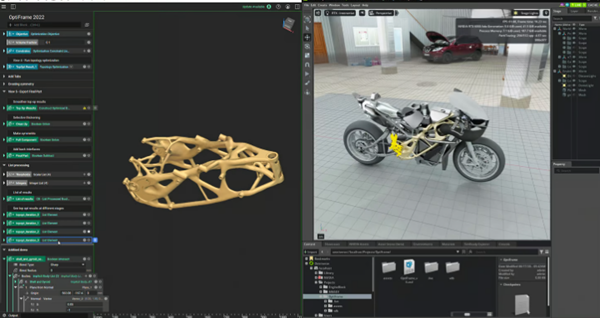

Integrating Autodesk Fusion CAD software with nTop allows designers to incorporate parts designed using implicit modeling into Fusion assemblies (Source: nTop)

With implicit files,“Not only did we get rid of the STL and grid, but we got a much smoother way of working,” Trevisan said. “Therefore, compared to STL and grids, I think implicit modeling is the future.”

Fusion CAD software maker Autodesk recently launched integration with nTop (nTop for Fusion App), allowing designers to import .implicit files directly into multi-component products. The image above shows how a motorcycle part optimized in nTop is imported into this Fusion design for assembly and simulation.

Fusion also has implicit modeling capabilities for mesh, and reportedly has larger plans for implicit modeling in CAD. Fusion has its own metal part preparation software and integrations with 3D printer manufacturers such as Renishaw to directly 3D print .implicit files, on par with the new Magics integration.

software manufacturerHexagon can now also read nTop’s .implicit files and run complex simulations on them, while other simulation software vendors, including Intact for FEA simulations and CloudFluid for CFD flow simulations, can now also read the files. .implicit.

“What’s interesting about these partners is that they simulate directly from implicit, which means very fast simulations,” Rothenberg said. “This is very useful in the early stages of design, when engineers want to quickly evaluate many different variants and understand their relative performance without having to run high-precision simulations that require meshing and lengthy runs. This way, engineers can do DOE very quickly. and refine design direction more quickly.

but maybe withThe new integration with Magics will further drive the application’s growth, as Magics is the file preparation software used by most metal laser powder bed fusion 3D printer owners.

“We believe the future of 3D printing lies in seamlessly processing large and highly complex files, and our partnership with nTop is a key step in that direction,” said Udo Eberlein, vice president of Materialize Software. “By integrating nTop’s implicit modeling core with our Magics software and NxG Build Processor, we are significantly improving the efficiency and reliability of our design-to-manufacturing process. This collaboration not only removes existing limitations, but also accelerates the development of innovative 3D printing applications. enables engineers to bring their high-performance designs to life with unprecedented ease and speed.

Make cylinder head

As you might have guessed,The optimized cylinder head of Wärtsilä’s engine is a demonstration project but has strong strategic value, says Trevisan. As one of the most critical components of an engine (we’re talking about a large 18-cylinder cargo engine), the entire validation process can take five to ten years. Therefore, the short-term goal of the project is to carry out one of the most challenging case studies to demonstrate its application. “We can then apply the same concept to many different technical areas of the engine,” Trevisan noted.

Although Wärtsilä printed three30% of the prototype size, but the company has yet to print a full-size cylinder head. Hong said that using the Nikon SLM NXG 600 laser powder bed fusion 3D printer, the expected printing time is about 10 days. Printing is expected to take place before the end of the year and will be followed by inspection and verification of the parts, as well as proof of their performance.

The inspection phase will show whether the part has achieved its goals of providing better cooling or performance.“It will also show if there are hidden problems that we didn’t anticipate,” Trevisan said, “or if there are other benefits.”

althoughNot all parts 3D printed by Wärtsilä require advanced design software like nTop, but Trevisan says he plans to use it more frequently now that it’s integrated into Magics.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.