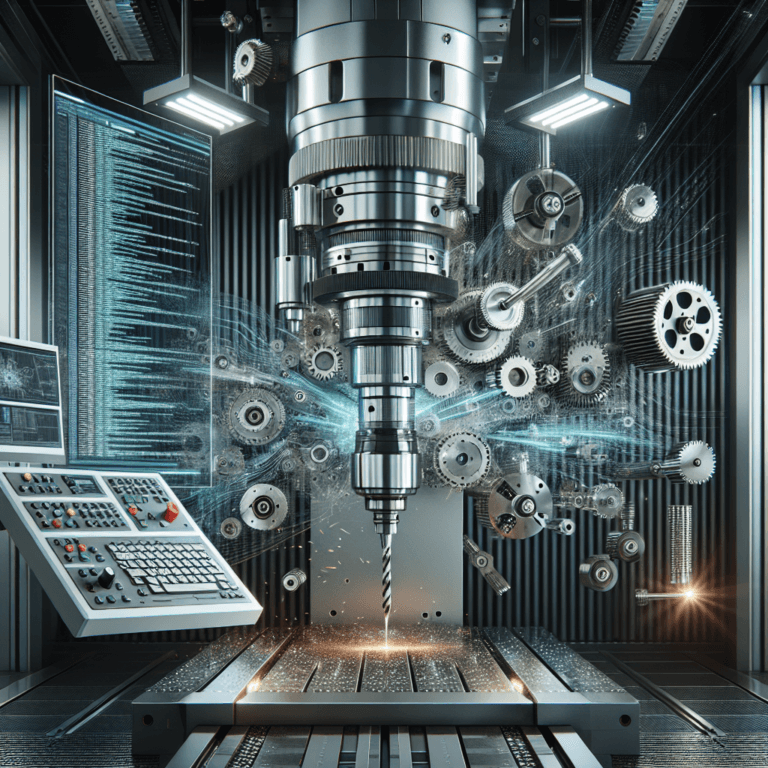

Understanding Horizontal CNC Drilling and Milling Machines

In the world of manufacturing, efficiency, precision, and versatility are essential components that drive success. As industry needs evolve, so too does the machinery that supports it. Among the various types of equipment, horizontal CNC (Computer Numerical Control) drilling and milling machines stand out for their numerous advantages. This article explores the key benefits of these machines, illuminating why they are a preferred choice for many manufacturers.

Enhanced Precision in Machining

Superior Accuracy Through Advanced Technology

One of the primary advantages of horizontal CNC drilling and milling machines is their capacity for high-precision machining. The integration of advanced computer technology allows operators to execute tasks with remarkable accuracy. This precision is crucial in industries where even minor deviations can result in defective parts, increased waste, and financial loss.

Consistent Quality Assurance

Horizontal CNC machines are designed to maintain consistent quality across multiple workpieces. By utilizing digital controls, these machines reduce the likelihood of human error, ensuring that each product meets the exact specifications required. This consistency is particularly valuable in industries like aerospace and automotive, where precision components are critical.

Increased Productivity

Efficient Workflow Design

Horizontal CNC drilling and milling machines facilitate a streamlined production process. The horizontal layout allows for faster tool changes and easy access to the workpiece, significantly reducing downtime. Operators can accomplish multiple tasks without manual repositioning of parts, leading to an overall increase in productivity.

Capability for High Volume Production

These machines are designed to handle high volumes of production with minimal intervention. The automated capabilities mean that while one batch is being processed, the operator can prepare the next, thereby maximizing time and resources. This efficiency is particularly beneficial for manufacturers who require large quantities of consistent parts.

Versatility of Applications

Multi-Functionality in a Single Machine

Horizontal CNC drilling and milling machines offer versatility that many manufacturers value. They can perform a variety of tasks, including drilling, routing, and milling, making them ideal for complex machining applications. This multi-functionality means companies can invest in one machine to cover several processes, significantly reducing capital expenditure.

Adaptability to Different Materials

These machines are not only versatile in function but also in the materials they can handle. Whether working with metals, plastics, wood, or composites, horizontal CNC machines can be equipped with different tooling to accommodate various materials. This adaptability allows manufacturers to respond quickly to market demands and incorporate new materials without significant machinery changes.

Enhanced Safety Features

Reduced Risk of Accidents

Safety is a top priority in any manufacturing environment. Horizontal CNC drilling and milling machines incorporate several safety features designed to keep operators safe. Automatic tool changers, enclosed working environments, and advanced monitoring systems reduce the risks associated with manual machining processes.

Improved Ergonomics

The design of horizontal machines often prioritizes operator comfort and safety. The ability to access workpieces easily without awkward positioning reduces the physical strain on operators and the likelihood of work-related injuries. A well-designed workspace leads to a more efficient workforce and a decrease in missed workdays due to injury.

Cost Efficiency

Lower Operational Costs

Investing in horizontal CNC drilling and milling machines can lead to substantial cost savings over time. The ability to execute multiple operations in a single setup minimizes the need for additional machines, which can be costly both in terms of acquisition and maintenance.

Reduced Waste and Material Savings

The precision of CNC machines leads to a reduction in waste during the machining process. Operators can create parts that require less finishing or adjustment, and the consistency in production reduces the likelihood of defects that could lead to costly scrap. These factors contribute to a lower overall material cost and higher profitability for manufacturers.

Streamlined Maintenance and Upkeep

Simplified Maintenance Procedures

Although any machine requires regular maintenance, horizontal CNC drilling and milling machines are designed with user-friendly maintenance in mind. The horizontal layout often allows for easier access to vital components, making servicing and part replacement more straightforward. This ease of maintenance enhances machine longevity and reduces unexpected breakdowns.

Utilization of Predictive Maintenance Technologies

Modern horizontal CNC machines frequently incorporate predictive maintenance technology, which leverages sensors and data analytics to anticipate equipment failures before they happen. This proactive approach not only prevents costly downtimes but also optimizes maintenance schedules to occur during non-production times.

Integration and Compatibility with Modern Manufacturing

Supporting Industry 4.0

The rise of Industry 4.0 has ushered in a new era of manufacturing characterized by automation, data exchange, and IoT (Internet of Things) technologies. Horizontal CNC drilling and milling machines are well-positioned to integrate with these advancements, allowing manufacturers to develop smart factories. This compatibility enhances operational efficiency, reduces lead times, and fosters innovation in product development.

Seamless Integration with CAD/CAM Software

Another significant advantage of horizontal CNC machines is their ability to work seamlessly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration enables manufacturers to turn digital designs into physical products with precision and speed, minimizing the guesswork involved in transitioning from concept to production.

Conclusion

Horizontal CNC drilling and milling machines present a plethora of advantages for modern manufacturers seeking efficiency, precision, and versatility. From enhanced productivity and precision to cost savings and safety features, these machines are integral to maintaining a competitive edge in today’s fast-paced manufacturing landscape. As technology continues to advance, the role of horizontal CNC machines will only grow more prominent, making them a wise investment for industries looking to innovate while remaining operationally efficient. Embracing this technology is not just about keeping up with the competition; it’s about redefining what is possible in machining processes.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.