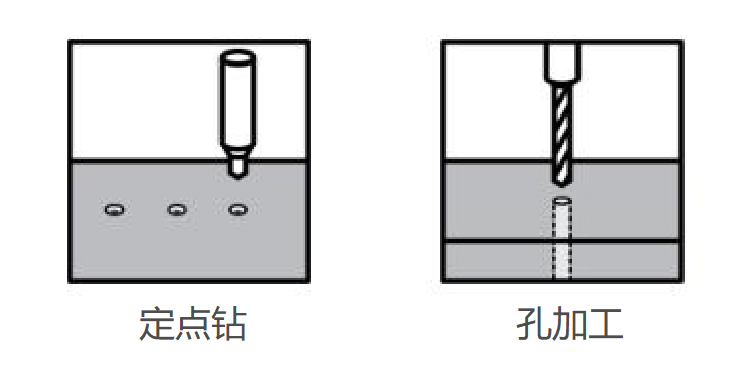

Fixed-point drilling: The first step in precise drilling can be difficult. Material characteristics, surface irregularity and drilling point geometry can be a factor that causes inaccurate drilling. If the fixed point drill is used correctly, the possibility of “slipping” the drill hole will be eliminated and will help ensure that the final product is more precise.

1

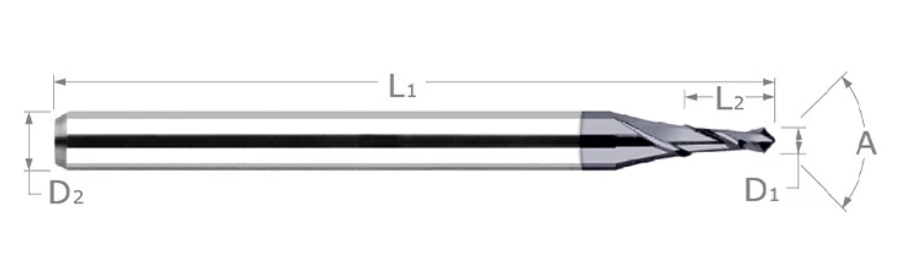

Choose a fixed point drill

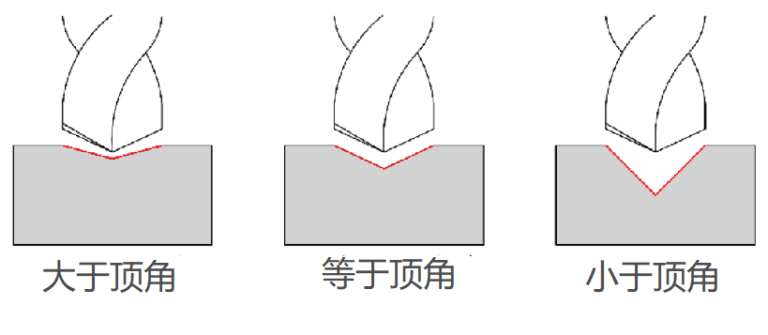

Ideally, the center of the hard alloy drill head should always be the first point of contact with the workpieces. Therefore, the top angle of the fixed point drill should be slightly larger than the top of the drill.

If the upper angle of the positioning drill is smaller than that of the drill, when the outside of the cutting surface is contacted before the workpiece, the drill may be damaged due to impact loading. It is also acceptable to use the angle of the drill head angle.

Figure 1 illustrates the required effect. On the left, an exercise enters the point before forming before. On the right, a drill approaches an area with angles that are too small. (Relative to the angle of the heart head and heart drill)

Left Figure 1: Concentrated Drill Top Angle> Top Angle Drill Bits (Recommended)

Average figure 2: upper angle of concentrated diamond = upper angle of Beng diamond

Right Figure 3: Top Angle of Concentrated Drilling

2

Mark your fixed point position

The purpose of a fixed point drill is to form a small pre-drift hole when starting to ensure the center of the drill. However, some operators have different reasons for choosing to use these tools – the top of the hole drilling is used. When leaving the chamfing, the screw head is flat with the surface of the part after viewing.

3

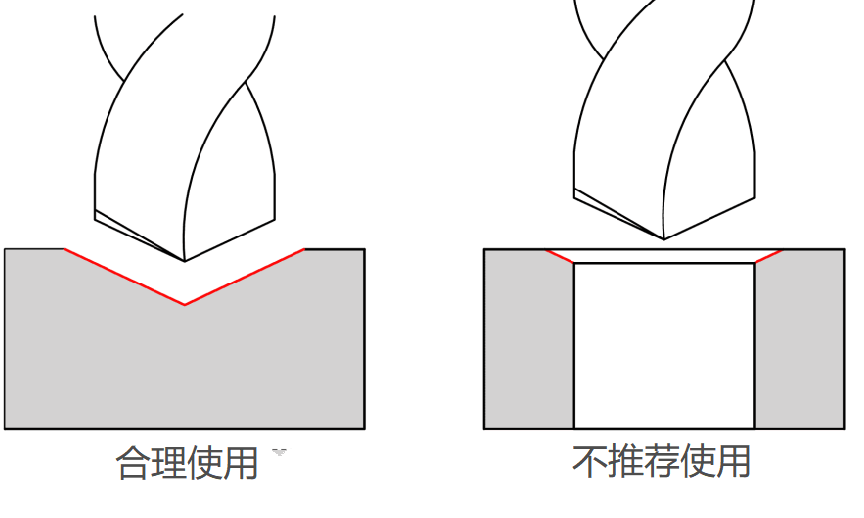

What will happen if the drill bit with improper angle of use

The drill with a larger top angle can find the correct position by guiding the top angle of the drill head to the center. If the outer diameter of the hard alloy drill is first exposed to the workpiece, the tool may be broken. This will damage the workpiece and cause the knife to fail.

If the two cutting blades of the drill are slightly different, one of them may be in contact with the other. This can make drilling inaccurate, and it may be meaningless to do the work before drilling.

4

Avoid using fixed point drills in “sliding” Processing Center

Few CNC processing applications need to be exact like drilling. Pores, deep pores, parts and smoothness are important. In other words, precision is crucial – none of the predetermined positions that do not have precise parts or accidentally deviating from the exercises during the treatment process than “sliding”. So how does drilling happen? How to prevent it?

To understand the “slip” of the drill, you can imagine the movement of the nail on a piece of wood with a hammer. Customizing sharp nails to the appropriate wooden surface can cause precise and direct impact. However, if other variables play a role – surface, blade, blade, improper impact – the blade mouth may enter the material at a certain angle, an inaccurate position, or not. For the drill hole of CNC machine tools, the drill bit is obviously a key factor in successful operation – a clean and clear blade – If used correctly, it will greatly help in obtaining efficient and precise final parts.

In order to reduce factors that are not good for treatment, such as uneven parts or exercises that are lightly used, a simple way to avoid “slipping” is to use fixed point exercises. The design goal of the tool is to leave a dental on the surface of the parts so that the drill bit can be combined during the drilling process to hold it properly to prevent the drill head from overshooting the route.

5

What situations cannot be used to use fixed point exercises?

When processed is an irregular surface, such as the side side or inclined plane of the cylindrical body, this fixed point drill may not be enough to hold the hole in a correct position. For these situations, flat diamonds may be more suitable.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.