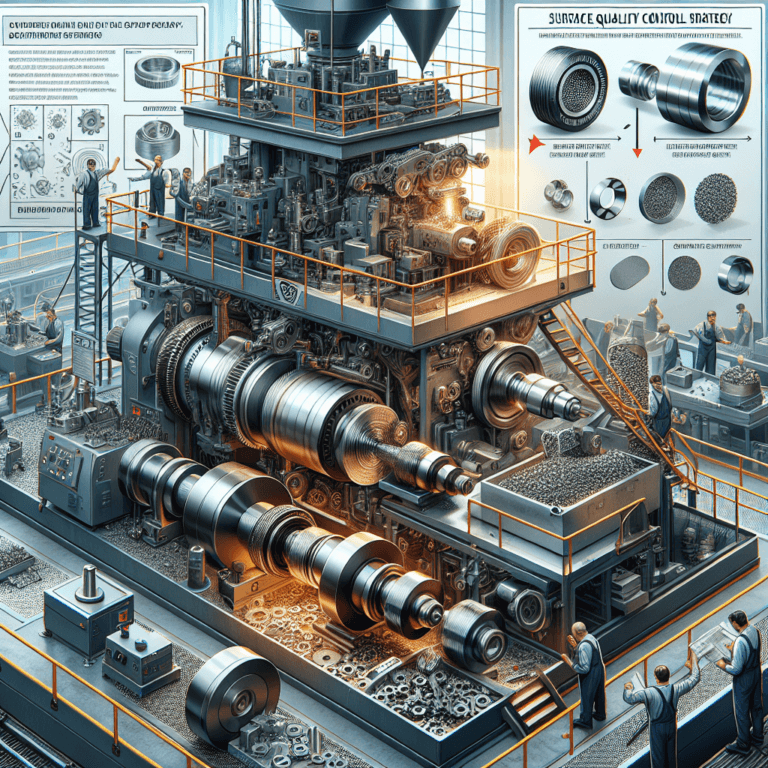

Introduction to Surface Quality Control in Double-Sided Grinding and Polishing Machines

In the world of precision manufacturing, surface quality plays a crucial role in determining the performance and longevity of various components. Double-sided grinding and polishing machines are widely used in industries such as semiconductor manufacturing, automotive, and aerospace, where high precision and exceptional surface finish are paramount. Implementing a robust surface quality control strategy in these machines not only enhances product quality but also improves overall production efficiency. This article delves into the various strategies and techniques employed to ensure optimal surface quality in double-sided grinding and polishing operations.

The Importance of Surface Quality

Surfaces that are improperly finished can lead to a myriad of issues, including increased friction, wear, and corrosion, which can subsequently result in premature failures. In applications such as optical components or semiconductor wafers, even the smallest imperfection can drastically affect performance, leading to significant economic repercussions. Therefore, establishing a rigorous surface quality control strategy is vital for manufacturers aiming for excellence.

Key Factors Influencing Surface Quality

Achieving the desired surface quality in double-sided grinding and polishing involves various interrelated factors:

1. Machine Setup

The initial setup of machinery is one of the most critical aspects of maintaining surface quality. Proper alignment, balance, and calibration will ensure that both sides of the workpiece are ground or polished evenly. Any misalignment can result in uneven surfaces that fail to meet quality standards.

2. Tooling and Abrasives

The choice of abrasives and tool geometry plays a vital role in determining surface quality. Factors such as grit size, material composition, and bonding type directly influence the machining process. Selecting the appropriate abrasive for the material being processed is crucial, as it affects the removal rate and surface finish.

3. Process Parameters

Parameters such as feed rate, speed, pressure, and cooling methods can significantly influence surface quality. Adjusting these parameters to find the optimal setup for specific materials is essential to achieving consistent results. For instance, a slower feed rate may yield a smoother surface but could also slow down production.

4. Workpiece Material

The physical and chemical properties of the workpiece material impact the surface finish. Tougher materials may require more robust tooling and a different approach altogether, while softer materials might need gentler processes to prevent surface damage.

5. Environmental Factors

Temperature, humidity, and even the cleanliness of the workspace can affect surface quality. Contaminants in the air or on the workpiece can lead to defects during grinding and polishing. Maintaining a controlled environment reduces the risk of such quality issues.

Developing a Quality Control Strategy

To ensure consistent surface quality, a comprehensive quality control strategy must be established. This strategy typically includes the following elements:

1. Regular Monitoring and Inspection

Employing measurement techniques such as Surface Roughness Measurement (SRM) and Optical Profilometry will provide quantitative data on the surface finish. Regularly scheduled inspections can help identify potential issues before they escalate. Utilizing digital tools for data analysis can facilitate timely interventions.

2. Implementation of Control Charts

Control charts are indispensable for monitoring variations in the surface quality process. By plotting surface roughness measurements over time, manufacturers can identify trends, detect outliers, and make data-driven decisions to adjust process parameters accordingly.

3. Training and Development

Educating operators about the importance of surface quality and the implications of deviations can lead to more conscientious handling of machinery. Training should encompass everything from machine operation to basic troubleshooting techniques.

4. Maintenance and Calibration

Regular maintenance and calibration of machinery are crucial in ensuring operational efficiency and accuracy. A well-maintained machine will provide more consistent results, thereby enhancing surface quality. Scheduled maintenance should include checking tool wear and verifying that the grinding and polishing heads are functioning within specified tolerances.

5. Root Cause Analysis

Whenever surface quality issues are identified, conducting a thorough root cause analysis can uncover underlying problems that need addressing. This technique not only helps in finding the immediate cause but also provides insights into long-term improvements.

Technologies Enhancing Surface Quality Control

Recent advancements in technology have offered new avenues for improving surface quality control in double-sided grinding and polishing machines:

1. Automated Process Monitoring

Automation can introduce precision into the monitoring process. Features such as real-time feedback mechanisms allow for instantaneous assessment and immediate corrective action if surface quality metrics fluctuate beyond acceptable limits.

2. Advanced Analytics

The use of data analytics, especially predictive analytics, can process vast amounts of data collected during machining operations. Predictive maintenance algorithms can anticipate when a machine is likely to malfunction, allowing for timely maintenance and reduced downtime.

3. Integration of AI

Artificial Intelligence (AI) has begun to influence manufacturing practices significantly. AI algorithms can learn from historical production data to predict optimal machining conditions and reduce process variability.

4. Machine Learning for Process Optimization

Machine learning techniques can analyze complex relationships within data to determine the best machining parameters. This approach can be particularly valuable in creating a feedback loop that continuously improves processes based on real-time information.

The Future of Surface Quality Control

As industries strive for greater accuracy and efficiency, the future of surface quality control in double-sided grinding and polishing is ripe for growth. Emerging technologies, such as Industry 4.0 solutions, will integrate IoT devices and create smart factories where real-time data will drive decisions.

Furthermore, sustainable manufacturing practices are becoming increasingly critical. Implementing eco-friendly abrasives and coolant systems that minimize waste while maintaining superior surface quality will become essential for future-proofing manufacturing processes.

Conclusion

Surface quality control in double-sided grinding and polishing is a multifaceted discipline that requires careful consideration of numerous factors. By adopting a comprehensive strategy that includes monitoring, inspection, process optimization, and embracing technological advancements, manufacturers can achieve unparalleled surface quality. As industries continue to evolve, maintaining a focus on quality will remain a cornerstone of successful manufacturing operations, leading to enhanced performance and customer satisfaction in the long run.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.