In the world of metal processing and manufacturing, efficiency is crucial, and every machine matters. One vital component that enhances productivity and cleanliness in this environment is the step-by-step chip conveyor. This sophisticated apparatus serves not just as a means of transporting shavings and chips generated during machining processes, but also as an essential metal processing assistant that contributes to effective cleaning and maintenance.

What is a Step-by-Step Chip Conveyor?

A step-by-step chip conveyor is a type of conveyor system specifically designed to handle the chips and swarf that are produced when cutting or machining metal. Unlike traditional conveyor systems, step-by-step chip conveyors are uniquely engineered to minimize the accumulation of waste, thereby ensuring smoother operational flow in manufacturing environments.

Key characteristics of step-by-step chip conveyors include:

Modular Design: Many models are built in a modular format that allows for easy customization and adaptability to different machinery and workspace layouts.

Efficient Chip Handling: These conveyors can manage various types of materials, from fine metal dust to larger scrap pieces, ensuring a comprehensive approach to waste management.

- Automated Operation: Most modern versions feature automation capabilities that allow for seamless integration into existing workflows, reducing the need for manual intervention.

Importance of Chip Conveyors in Metal Processing

When producing metal components, chips and shavings are unavoidable. If left unchecked, these by-products can lead to a range of issues, including:

Safety Hazards: Accumulated chips can create tripping hazards and increase the risk of fire due to the flammable nature of certain metal shavings.

Machine Efficiency: Excessive waste buildup can interfere with the operation of machinery, leading to increased wear and tear, potential breakdowns, and costly downtime.

- Emphasis on Cleanliness: A clean workspace is vital for maintaining high standards of production. Continuous cleaning reduces contamination risks and maintains quality control.

Implementing a step-by-step chip conveyor system allows manufacturers to tackle these concerns proactively, ensuring that they can maintain smooth operations and a safer work environment for their employees.

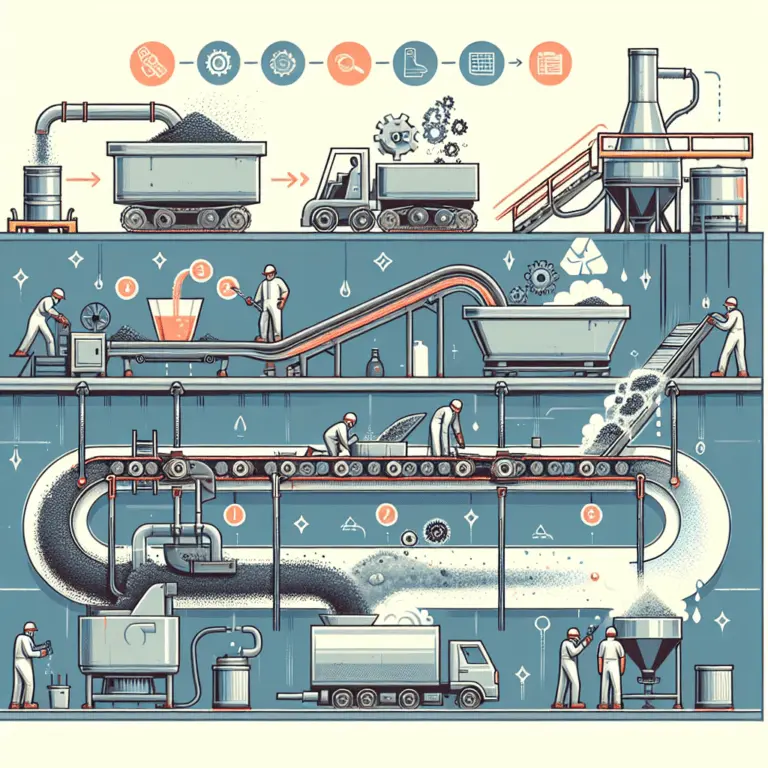

Step-by-Step Guide to Implementing a Chip Conveyor

To seamlessly integrate a step-by-step chip conveyor into your metal processing operation, follow these steps:

Step 1: Assess Your Needs

Before investing in a chip conveyor, it is essential to evaluate your specific processing requirements. Consider the following:

Volume of Material: Analyze the quantity and type of chips produced by your equipment. This will determine the type of conveyor that will best suit your needs.

- Types of Chips: Different machining processes produce different types of chips, whether they are long and stringy, short and thick, or fine dust-like. Your conveyor must be able to accommodate these varieties.

Step 2: Choose the Right Conveyor Design

Once you have assessed your needs, you can explore different designs available in the market. Common configurations include:

Drag Chain Conveyors: Ideal for heavy chips, the drag chain design effectively moves larger waste materials through a series of connected links.

Belt Conveyors: For finer materials, belt conveyors are suitable for transporting chips away from machine tools without risk of spillage.

- Screw Conveyors: These are beneficial in environments where space is limited, as they can be installed vertically or horizontally to save on footprint while efficiently transporting waste.

Step 3: Installation Process

Installing a step-by-step chip conveyor is a task that requires careful planning and execution. Follow these steps:

Prepare the Site: Ensure that the workspace is clear and properly formatted for installation.

Position the Conveyor: The location should offer easy access to the machine tools from which the chips will accumulate.

Connect to Key Equipment: Make sure the conveyor is integrated with the machinery, allowing for automatic chip transfer.

- Test Run: Before fully launching the equipment in production, conduct a test run to ensure operation efficiency and troubleshoot any issues.

Step 4: Regular Maintenance

To maximize the lifespan and efficiency of your chip conveyor, regular maintenance is crucial. This may include:

Cleaning: Periodically remove any build-up of material on conveyor components that could result in dysfunction.

Inspecting for Wear: Regular checks on moving parts, drive systems, and belts will help catch any potential issues before they escalate.

- Lubrication: Keeping moving parts well-lubricated will ensure smooth operation and further extend the life of the conveyor system.

Benefits of Using a Step-by-Step Chip Conveyor

Choosing to install a step-by-step chip conveyor in your metal processing facility comes with numerous advantages, including:

Enhanced Operational Efficiency

By automating the removal of chips and swarf from the processing area, you eliminate the labor-intensive task of manual clean-up. This allows your operators to focus on machining and production tasks, boosting overall productivity.

Improved Workplace Safety

With a dedicated system for managing metal waste, you significantly reduce hazards associated with accumulated chips. A cleaner workplace not only complies with safety regulations but also promotes employee wellbeing.

Cost-Effectiveness

While there is an upfront cost associated with purchasing and installing a chip conveyor, the long-term savings realized through reduced downtime, maintenance costs, and increased productivity lead to a positive return on investment.

Environmental Considerations

Efficient chip removal leads to more sustainable operations, as properly handled metal waste can be recycled or repurposed. This reduces your facility’s environmental impact and contributes to a more eco-friendly industry.

Conclusion

A step-by-step chip conveyor is more than just a mechanical apparatus; it is a crucial ally in the realm of metal processing. By enabling effective cleaning and waste management, these systems not only enhance operational efficiency but also contribute to a safer and more sustainable workspace. As industries continue to evolve, staying up-to-date with such advanced machinery will be key to maintaining competitive advantages and meeting the demands of a rapidly-changing manufacturing landscape. Investing in a quality chip conveyor system can significantly impact the productivity and safety of your operations while supporting long-term sustainability goals. Making this investment today will ensure that your facility thrives well into the future.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.