1

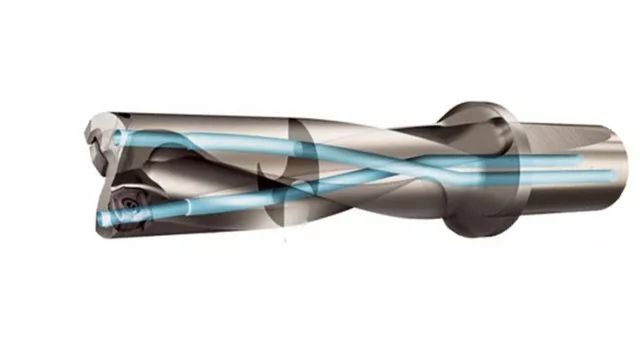

The structure and characteristics of diamond U

Structure: indexable insert, screws, support parts.

The U drill adopts a hole pressing structure, and the indexable insert with chip breaking mechanism with reasonable geometric parameters is fixed at the front end of the cutter body with screws to form the cutting part of the drill. There are two chip flutes on the cutter body and an internal cooling hole that guides the cutting area to carry coolant. The shank of the cutter body can be made into a straight shank or a taper shank to facilitate the connection of different equipment.

2

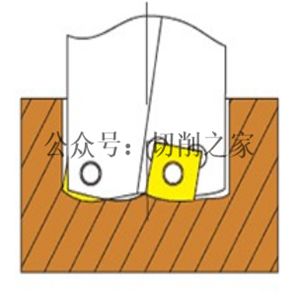

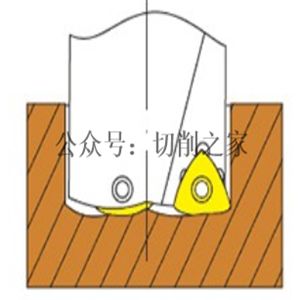

U drill blade shape

Blade specifications: SP (left image) WC (right image), etc.

Most indexable inserts are tightened by tapered end screws, consisting of inserts and screw holes. The centers of both are offset (0.15 to 0.2 mm). When tightening the screws, a downward pressure and positioning surface can be produced. The component forces the blade firmly.

3

The structure of the cutting body of the U drill

The structure of the cutter body of the U drill is the key to the U drill. Whether the structure of the cutter body is reasonable or not directly affects the manufacturing quality of the U drill. Therefore, the design and processing attach great importance to the structure of the cutting body of U-drills. Generally speaking, the structure of the cutting body of U-drills mainly refers to chip flutes, insertion grooves, coolant holes , to the shoulders of positioning and clamping surfaces, etc.

4

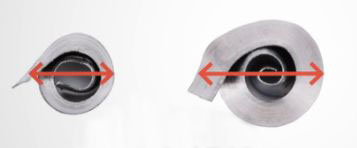

Chip flute for U-drill

Straight and spiral grooves

Generally, when the bit is not rotating, straight grooves are used. The bit uses straight or spiral flutes when rotating.

Note: The chip flute of the U drill directly affects the strength of the cutter body.

The geometry is closely related to the chip breaking and chip removal capabilities of the U drill. If the chip removal capability of the U drill is insufficient and the chip groove is severely blocked, the body of the cutter will not be able to turn. The U-shaped cutter body will generate significant torque, which will eventually cause the cutter to break overall. body.

In terms of chip removal and breaking capabilities, spiral grooves are better, but there are some problems with the layout and design of the U-drilled internal cooling holes of spiral grooves. The internal cooling holes of some U-drills are designed on-axis, so the resistance is inherently lower than that of the core drill. In addition, if the internal cooling hole of normal bar material is made into a spiral, the cost will be slightly higher.

Therefore, the following conditions must be met during processing:

1. High resistance to torque and bending deformation.

2 Optimized cutting flow space.

3 Optimal injection position and flow space of the coolant.

5

Points to note when processing U-drills

1. When installing the U drill, pay attention to the front and rear directions, which blade is up, which blade is down, which is facing inward and which is facing outward .

2. The center height of the U-drill needs to be corrected. The control range is required depending on its diameter. It is generally controlled within 0.1 mm. The smaller the diameter of the U-drill, the higher the center height requirement. The center height is not good for both sides of the U-drill. It will wear out, the hole diameter will be too large, the blade life will be shortened, and small U-drills will break easily.

3. U-drills have very high coolant requirements. It is necessary to ensure that the coolant is ejected from the center of the U-drill. The higher the pressure of the coolant, the better you can block the exit of excess water. the turret to ensure its pressure.

4. The cutting parameters of the U drill strictly follow the manufacturer’s instructions, but different brands of blades and power of the machine tool should also be considered. During processing, you can refer to the load value of the machine tool and make appropriate adjustments. Generally, high speed and low feed are used.

5. U-drill blades should be checked frequently and replaced in time. The different blades must not be installed upside down.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.