when it comes to 3D When it comes to the benefits of printing, two are often mentioned: the ability to customize parts and a cost-effective way to achieve small to medium volume production. Based in Germany IBL Hydronics The company is a company that is committed to doing3DA company that maximizes the benefits of printing technology.It’s understoodthe company has turned to selective laser sintering to help produce custom control systems for machines and vehicles, among other applications. (SLS)technology, in particular form laboratoriesbusiness Fuse 1 Ecological printing system.

Since 1987 year by Dr-IngThomas Hole Since its creation,IBL Hydronics Known for its custom electronics, hydraulics and software solutions. It operates in various business fields, including construction, agriculture and forestry, and special machinery and vehicles. The company primarily produces its components in-house and focuses on solving each customer’s individual challenges and needs, developing specific solutions for each customer. For these reasons,3D Print via form laboratories ofFuse1 SLS 3D Model Printers are the ideal solution.

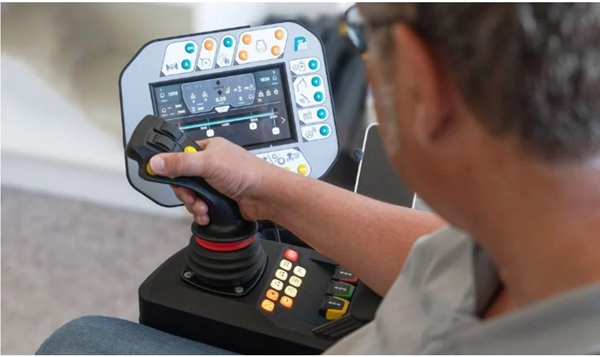

△The control panel shell components are made of nylon 12 Print in Fuse 1 lit, then smoothed and tinted (Photo source:form laboratories)

Also,IBL Hydronicsnot the only ones to benefit form laboratories Technical people. In recent years,form laboratories exist SLS And YEARS Continuous innovation in solutions can be used in more areas and more applications. The company will be inNext form 2022stand ( 11.1 showroom,E11 stand) exhibitions and demonstrations Fuse 1+ 30Wand other products, including IBL Hydronics of parts. Attendees of this additive manufacturing event can see 3D SLS Learn how printing can be used for functional prototypes and complex end-use hydraulic parts. form laboratoriesother technical solutions.

Will 3D SLS Print for custom automation control systems

WhenIBLRealizing that they had reached the structural and conceptual limits of traditional production processes, they began to consider3D If printing can provide new solutions. Industry trends also encourage them to do so, as the company, like many others in the industry, tends to produce vehicles and equipment in small series, approx.100arrive250parts. This makes investing in a large in-house production fleet extremely expensive, especially for traditional methods such as injection molding.

After trying different 3D After printing technology, they 2019 invested in form laboratories of Fuse 1 SLS 3D Model printer. Since then, the company has continued to increase its 3D Printing activity to meet growing demand.IBL Hydronics of 3D Printing Technology Product Designer Tom Heindl Explained: “Having3D SLS Printers mean we no longer need to use CNC Manufacturing methods such as milling, turning or machining. Of course, this saves us a lot of time, money and space. ” 3D SLS Printing is particularly interesting because it allows printing without a support structure, opening the door to more valuable projects that were not previously able to be done.

△The special texture gives the model the appearance of leather, making it impossible to detect that the piece is actually 3D Printed (photo credit:form laboratories)

NOW,3D Printing plays a key role in companies creating their own solutions. The team is already seeing many benefits of additive manufacturing technology. The first, of course, is the speed and flexibility that this technology offers. These benefits are the basis of the new control module development process, allowing even significant design changes to be implemented quickly, with high-quality prototypes produced in two to three weeks. Additionally, they are able to focus on their customers’ needs at an unprecedented level, which is their unique selling point in the market. The company also highlights ease of use and, of course, more cost-effective part production.

3D SLS The importance of printing for a business is also reflected in IBL Success can be seen in the latest project, which provides a control panel for an agricultural machinery manufacturer that needs to be customized for a specific machine. Not only was the project completed in record time, with the control module completed and ready for presentation a month later, but 3D SLS Printing enables the creation of functional and visually appealing designs. The company plans to continue to grow and expand its horizons,Heindl concluded: “If we had not invested internally 3D printer and learn the process, we won’t get some customers. “

exist Next form 2022Discover it at the exhibition SLS More information on benefits

certainly,IBL The case is simply usingform laboratories of SLS And 3D SLA One of the many applications complemented by printing solutions. For those interested in learning more about these technologies,form laboratories will be in Next form of 11.1 showroom E11 Other application cases will be presented to different users on the stand. And IBL Together, participants will be able to view the content of Vital Auto、XSpectre Or german railway Example of customer waiting.

△form laboratorieswill be in Next form presenting its new flagship product SLS printer Fuse 1+ 30W and other solutions

Also,form laboratories A new solution will be presented at the show.Fuse 1 tracking products and Formlabs SLS Next product in the series Fuse 1+ 30W will be with Form 3+、Form 3B+、Shape wash、FormCure、Form 3L、Form 3BL And 40Exhibit together+ High performance materials.Fuse1+ 30W Particularly exciting because form laboratories Noting that it prints twice as fast as the previous generation, it also paves the way for the use of new high-performance materials.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.