Worm screws generally have a large pitch. Due to the characteristics of their tooth profile, the contact surface between the cutting edge and the workpiece is large. During processing, it is very easy to damage the cutting tool due to the extrusion of iron filings in between. the workpiece and the cutting tool. Although the operator can use tools with flexible tool shanks and feed with small cutting depth, the above problems cannot be fundamentally solved.

The same problem arises when machining worm gears on CNC lathes. The machine tool will never automatically stop due to tool chipping, so this problem is even more difficult to solve. Ordinary horizontal hand-operated lathes can be flexibly controlled by the operator according to the cutting situation, and can even retract the tool halfway during processing, avoiding a worse situation.

A method given below is to use the rigid processing method of CNC lathes and its precise positioning function to synthesize the two side lines of the trapezoid using the method of “connecting points to form a line”, thus effectively solving this issue.

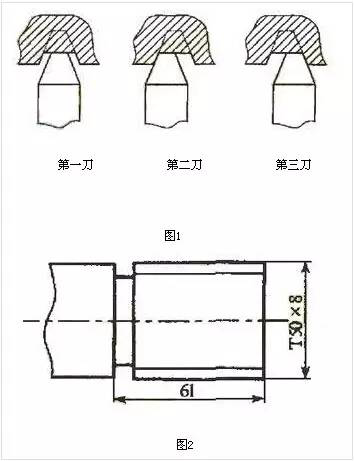

Cutting tools can be made of carbide forming tools. This cutting method turns one knife into three, reducing cutting resistance. The schematic diagram is shown in Figure 1. This method is actually a flexible use of the left and right cutting method. The author changed it to “center, left, right” cut, because if you don’t make a cut from the middle first, the iron filings will still grip the surface. cutter. This is derived from reality in conclusion.

Different from the left and right cutting method of non-CNC lathes, “center, left and right” cutting on CNC lathes requires precise calculations. This calculation takes a little time, but it results in improved processing efficiency and peace of mind during. work. The cutting speed can be selected between 70 and 90 m/min and the cutting depth ap=0.1 to 0.15 mm (depending on the performance of the machine tool, its suitability depends on the thickness and the color of iron shavings).

The coordinate calculation method is shown below, see Figure 2.

cot=20°=1:0.364, i.e. when feeding 0.1 mm in Z direction decreases and increases by 0.0364 mm. You can first list the values as shown in the following table for easier programming.

Cutting left and right on the CNC actually means changing the Z coordinate of the starting point when threading. This must be kept in mind. The following takes Figure 2 as an example to give a program and corresponding instructions. The thread order is G92, the end face of the workpiece is the zero position in the Z direction, and the thread pitch is 8mm.

…

N110 GOO X55 Z10 quickly locates the thread starting point

First car cut N120 G92 X49.8 Z-60 F8 to X49.8

N130 GO1 W-1.42 F1 Change thread starting point

N140 G92 X49.8 Z-60 F8 left car

N150 G01 Z10 F1 Return to starting point

N160 W1.42 Change thread starting point

N170 G92 X49.8 Z-60 F8 right side of car

N180 G01 Z10 F1 Return to starting point in Z direction

First car cut N190 G92 X49.6 Z-60 F8 to X49.6

…

As shown in the example above, “middle, left and right” turning is carried out several times, cutting is easy, and chip evacuation is smooth. The goal of “connecting the dots to form a line” was achieved, transforming the limitations of the CNC into strengths. If coolant is added to remove iron shavings during cutting, the effect will be better.

Additionally, when processing parts such as square threads, you can also use turning tools narrower than the width of the groove and program using the above method. However, the program is much simpler and does not require a lot of calculations. is also very satisfying.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.