The modern landscape of manufacturing is vastly influenced by technological advancements. Among the various machining tools that have revolutionized precision engineering, the single spindle turret lathe stands out as a powerful assistant in high-precision manufacturing. This article explores the critical role of the single spindle turret lathe in the manufacturing process, highlighting its features, advantages, and applications, along with key insights into why it remains an essential tool in today’s manufacturing environment.

What is a Single Spindle Turret Lathe?

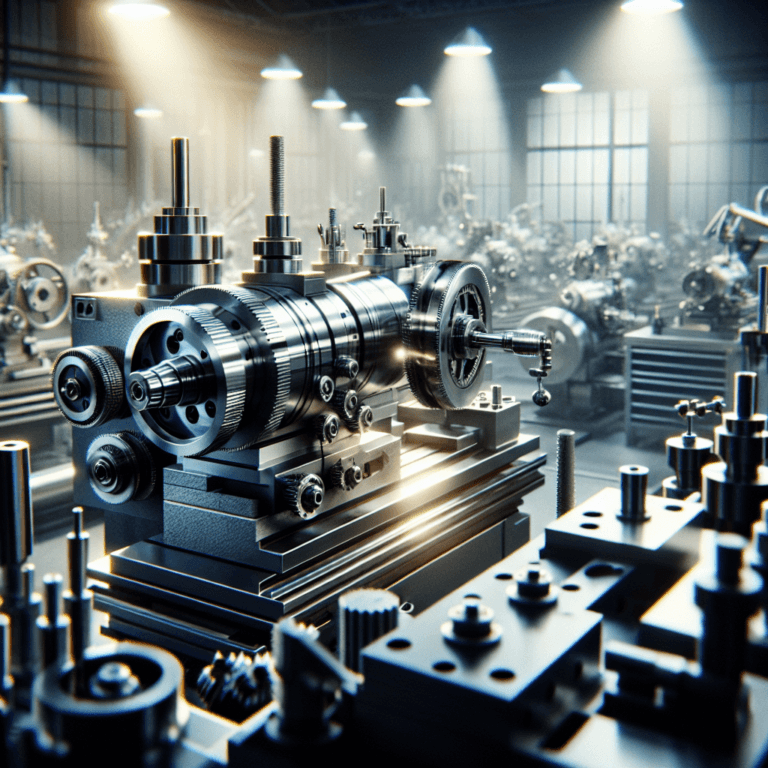

A single spindle turret lathe is a type of lathe machine characterized by a turret that holds multiple cutting tools and a single spindle for rotating the workpiece. This configuration allows for quick tool changes and efficient production of complex parts with high precision. Traditionally, lathes were limited to turning operations, but the turret design provides versatility by enabling various machining operations—like drilling, tapping, and milling—without the need for extensive reconfiguration.

Key Features of a Single Spindle Turret Lathe

Versatility: The turret can accommodate multiple tools, allowing operators to switch between different operations seamlessly. This capability enhances productivity, especially in batch production settings.

Automated Operations: Many single spindle turret lathes come with advanced control systems offering automation features. High-precision CNC (Computer Numerical Control) models ensure consistent performance and accuracy, thus minimizing human error.

Ease of Use: The design of single spindle turret lathes is generally user-friendly. Operators can quickly learn to utilize the machine effectively, which is vital in fast-paced manufacturing environments.

High Precision: One of the primary benefits of using a single spindle turret lathe is its ability to produce parts consistently, within tight tolerances. The high rigidity of the machine structure helps in reducing vibrations during machining, which contributes to better accuracy.

- Compact Design: Compared to multi-spindle machines, single spindle turret lathes are often more compact. This feature is crucial for businesses looking to maximize their floor space without sacrificing capability.

Applications of Single Spindle Turret Lathes

In the realm of high-precision manufacturing, single spindle turret lathes find applications across various industries, including:

Automotive Industry

In automotive parts manufacturing, high precision is essential. Single spindle turret lathes are often employed to produce intricate components such as gears, shafts, and brackets. Their ability to switch between tools rapidly makes them ideal for making variations of similar parts.

Aerospace Engineering

The aerospace industry demands extremely high-quality standards. Single spindle turret lathes are used to machine components such as engine parts, fuselage fittings, and landing gear components, where precision is non-negotiable.

Medical Device Manufacturing

Medical devices require components that meet stringent regulatory standards. Single spindle turret lathes enable manufacturers to produce intricate and precise components such as surgical instruments, diagnostic devices, and implantable equipment.

Agricultural Equipment

Machining parts for agricultural machinery requires durability and precision. Single spindle turret lathes help in manufacturing components that can withstand harsh conditions while maintaining operational efficiency.

Electronics and Telecommunications

In the electronics industry, precision components play a critical role in product functionality. Single spindle turret lathes are utilized to produce structural components, connectors, and casings with intricate designs.

Advantages of Using a Single Spindle Turret Lathe

Increased Production Efficiency

The design of the single spindle turret lathe allows for quick setups and tool changes, enabling continuous production without extensive downtime. This efficiency is particularly important in competitive manufacturing environments where time-to-market is crucial.

Cost-Effectiveness

Although the initial investment in a single spindle turret lathe can be significant, the long-term savings associated with reduced labor costs, minimized waste, and efficient resource utilization are noteworthy. Fewer machine setups are required, allowing operators to concentrate on production rather than constant adjustments.

Improved Quality Control

With automated features and high precision capabilities, single spindle turret lathes contribute to enhanced quality control. Consistent production of parts within specified tolerances is easier to achieve, reducing the potential for errors and defects.

Flexibility in Production

The turret’s ability to hold various tools allows manufacturers to produce a wide range of products without the need for multiple machines. This flexibility is essential not only for batch production but also for custom manufacturing projects.

Maintenance and Care for Longevity

To ensure a single spindle turret lathe operates at peak performance, regular maintenance and care are paramount. Here are some tips for effectively maintaining these machines:

Routine Lubrication: Ensure that the machine’s moving parts are adequately lubricated to reduce wear and tear.

Regular Calibration: Routine calibration ensures that the machine remains accurate and adheres to the required tolerances.

Cleanliness: Keeping the machine clean of chips, debris, and contaminants can enhance the machine’s longevity and performance.

Inspecting Components: Regularly inspect tooling and components for signs of wear or damage, replacing them as necessary to maintain precision.

- Operator Training: Ensuring that operators are properly trained and knowledgeable about the machine contributes significantly to its maintenance and operational effectiveness.

Future Trends in Single Spindle Turret Lathe Technology

The evolution of machine tools, including single spindle turret lathes, is ongoing. Manufacturers continue to integrate advanced technologies such as artificial intelligence, IoT (Internet of Things), and advanced data analytics into machine design, providing insights that drive efficiency and accuracy. These innovations will likely lead to more adaptable machines that can learn from previous operations and self-optimize in real time.

Additionally, as industries push for greener practices, the focus on energy-efficient designs and sustainable manufacturing practices is becoming imperative. Single spindle turret lathes that are energy-efficient and reduce waste will be favored as the manufacturing landscape evolves.

Conclusion

In high-precision manufacturing, the single spindle turret lathe proves to be an invaluable asset. Its versatility, efficiency, and ability to produce consistent, high-quality components make it essential across various industries. As technology advances, these machines will continue to evolve, integrating smart features that further enhance their capabilities. For manufacturers aiming to remain competitive and maintain high standards of precision, investing in a single spindle turret lathe is a step in the right direction towards achieving operational excellence and driving innovation.

Ultimately, the single spindle turret lathe serves not just as a tool, but as a powerful assistant in navigating the complexities of modern manufacturing with finesse and accuracy.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.