CNC gear shaving machines play an integral role in the manufacturing of precision gears, streamlining the production process and enhancing the quality of the final product. Among these advanced machines, single-axis CNC gear shaving machines stand out for their simplicity and efficiency. However, despite their robust design and automation advantages, these machines necessitate daily maintenance to ensure their optimal performance and longevity. This article will explore the importance of daily maintenance for single-axis CNC gear shaving machines, the key maintenance tasks, and best practices to follow.

## Understanding Single Axis CNC Gear Shaving Machines

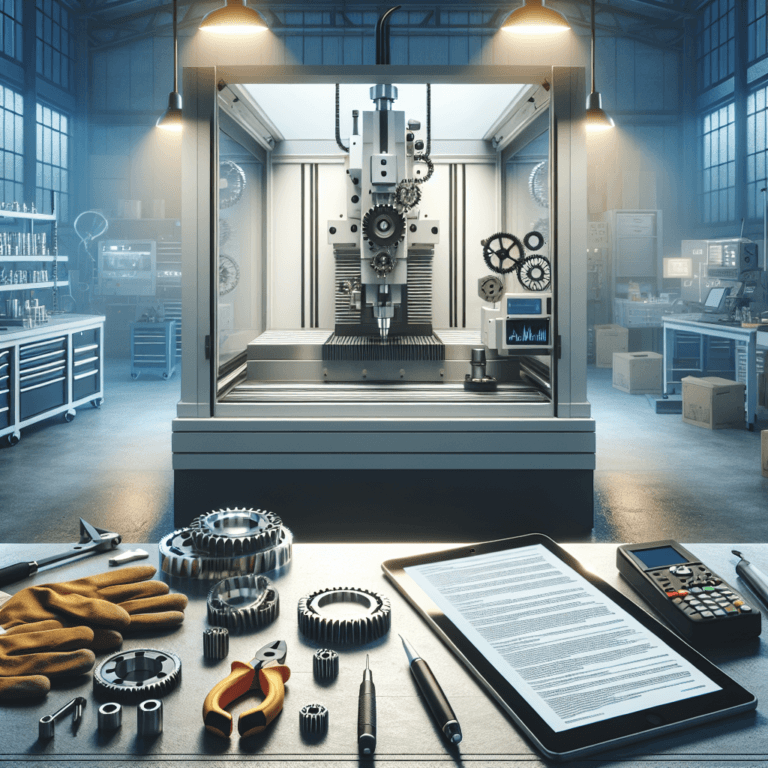

Single-axis CNC gear shaving machines are specifically engineered for the precise finishing of gear teeth. Unlike traditional gear manufacturing processes, which may be labor-intensive and time-consuming, CNC gear shaving machines utilize computer numerical control technology to automate the cutting process. This automation drastically improves production rates while maintaining uniform quality.

The single-axis focus allows for easier operational management compared to multi-axis machines. This type of gear shaving is particularly suited for producing high-precision gears used in industries ranging from automotive to aerospace. Therefore, understanding the machine’s operational capabilities and maintenance requirements is critical for manufacturers looking to maximize efficiency and product quality.

## The Importance of Daily Maintenance

Daily maintenance of single-axis CNC gear shaving machines is crucial for several reasons. Over time, neglecting regular upkeep may lead to decreased performance levels, increased production errors, and, ultimately, costly downtimes. Here are some of the primary reasons daily maintenance is essential:

### 1. Ensures Consistent Performance

Daily maintenance helps to ensure that machines operate smoothly and consistently. Regularly checking for wear and tear, ensuring proper lubrication, and cleaning the machine components can prevent any operational hitches that may arise from accumulated debris or worn parts.

### 2. Extends Machine Lifespan

All machines undergo wear and tear over time. However, implementing a rigorous daily maintenance schedule can mitigate these effects. Regular inspections and timely replacements reduce the likelihood of catastrophic failures, prolonging the overall life of the gear shaving machine.

### 3. Improves Product Quality

Precision is key in gear manufacturing, and even slight deviations can lead to significant issues. Regular maintenance helps in preserving the machine’s alignment and calibration, ensuring that the gears produced meet the necessary quality standards.

### 4. Reduces Downtime and Costs

When CNC machines break down, it can lead to significant production delays, affecting overall productivity. Daily maintenance reduces the risk of unforeseen breakdowns, thereby saving both time and money for manufacturers.

## Key Maintenance Tasks for Daily Upkeep

Understanding the specific maintenance tasks involved in daily upkeep helps operators to establish a thorough maintenance routine. Here are essential tasks to incorporate into daily maintenance checks:

### 1. Cleaning the Machine

Keeping the machine clean is foundational to its maintenance. Operators should wipe down surfaces regularly to remove metal shavings, oil, and other contaminants. A clean machine operates better and is less prone to unforeseen problems.

### 2. Checking Fluid Levels

CNC gear shaving machines rely on various fluids, including hydraulic fluid, lubrication oil, and coolant. Daily checks should include verifying that all fluid levels are adequate, and refilling them as necessary. Insufficient fluids can lead to overheating and operational inefficiencies.

### 3. Inspecting Cutting Tools

The cutting tools installed on the machine play a critical role in precision gear shaping. Daily visual inspections can help detect any signs of wear or damage. If tools are found to be dull or damaged, they should be replaced immediately to maintain cutting efficiency.

### 4. Monitoring Machine Alignment

Ensuring the alignment of the machine components is vital. Misalignment can lead to unanticipated errors in the final gear profile. Operators should routinely check the alignment settings and make the necessary adjustments.

### 5. Examining Electrical Connections

CNC machines depend on numerous electrical components for operation. Daily inspections of electrical connections, including wires, plugs, and circuitry, can help identify potential issues that could lead to machine failures.

### 6. Testing Safety Mechanisms

Safety should always be a priority in any manufacturing environment. Regularly testing the machine’s safety features ensures that they are in working condition, minimizing the risk of accidents.

### 7. Logging Maintenance Activities

Keeping a log of daily maintenance activities allows operators to track what tasks have been completed and when. This log can be invaluable for spotting trends over time that may indicate more significant issues.

## Best Practices for Daily Maintenance

To achieve effective daily maintenance of single-axis CNC gear shaving machines, operators should consider implementing the following best practices:

### 1. Develop a Checklists

Creating a detailed maintenance checklist can streamline the process. This list should include all the tasks that need to be performed daily, ensuring that no essential steps are overlooked.

### 2. Train Operators

Operators should be well-trained not only in the mashine’s operational processes but also in maintenance protocols. Regular training sessions can enhance their skills and knowledge.

### 3. Obtain Quality Replacement Parts

Using OEM (Original Equipment Manufacturer) parts for replacements ensures that machine performance is not compromised. Low-quality parts could lead to further damage or inefficient functioning.

### 4. Schedule Deep Maintenance

In addition to daily checks, scheduling deeper maintenance at regular intervals, such as weekly or monthly, ensures thorough inspection and service of the machine.

### 5. Maintain Documentation

Maintaining comprehensive documentation of all maintenance activities, including repairs and parts replacements, provides valuable insights into the machine’s performance history. This data can help operators detect patterns that might indicate future issues.

## Conclusion

In conclusion, single-axis CNC gear shaving machines are invaluable assets in the modern manufacturing landscape. Nevertheless, their efficiency and reliability hinge on the dedication to daily maintenance. By establishing a rigorous maintenance routine, manufacturers can ensure consistent performance, extend the machine’s lifespan, improve product quality, and reduce the risk of costly downtimes. Emphasizing preventive care not only enhances operational efficiency but also contributes significantly to the bottom line, making maintenance a top priority in any manufacturing facility.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.