In the realm of modern manufacturing, the quest for precision, efficiency, and complexity in component production has led to the widespread adoption of a transformative technology: Significant Impact CNC Machining Services. This term encapsulates far more than just the mechanical process of cutting material; it represents a comprehensive, technology-driven service that fundamentally alters product development cycles, enhances design possibilities, and elevates final product performance across countless industries. For engineers, designers, and procurement specialists seeking to bring innovative concepts to life, understanding the depth and breadth of these services is crucial for making informed sourcing decisions.

Deconstructing “Significant Impact”: Beyond Basic Machining

At its core, “Significant Impact” in this context refers to the profound effect these services have on the entire value chain. It’s not merely about removing metal or plastic to a shape; it’s about how advanced machining enables:

Radical Design Freedom: Complex geometries—undercuts, deep cavities, compound curves, and intricate internal channels—that were once impossible or prohibitively expensive with conventional machining become feasible.

Accelerated Time-to-Market: The integration of advanced CAD/CAM software with high-speed, multi-axis machines allows for the rapid transition from digital model to physical prototype and then to final production part.

Uncompromising Material Integrity: Precision machining minimizes heat-affected zones and mechanical stress, preserving the inherent properties of high-performance materials like titanium alloys, Inconel, or engineered plastics.

Supply Chain Simplification: A capable partner offering these services often provides a turnkey solution, encompassing design for manufacturability (DFM) analysis, material sourcing, precision machining, and comprehensive post-processing and finishing.

The Technological Pillars of High-Impact Machining

The capability to deliver such impactful results rests on several advanced technological pillars.

1. Multi-Axis CNC Machining: The Heart of Complexity

The evolution from 3-axis to 4-axis, and most powerfully, to 5-axis CNC machining, is the single greatest driver of impact. A 5-axis CNC machining center allows the cutting tool to approach the workpiece from virtually any direction in a single setup. This eliminates the need for multiple fixtures and manual repositioning, which translates to:

Dramatically improved accuracy (often achieving tolerances within ±0.001mm / 0.001 In), as all features are machined in one coordinated coordinate system.

Superior surface finish on complex contours.

The ability to machine monolithic components that would otherwise require assembly from multiple simpler parts, increasing strength and reliability while reducing potential failure points.

2. Advanced Software and Simulation

The physical machining is preceded by sophisticated digital workflow. Powerful CAM (Computer-Aided Manufacturing) software is used to generate optimal, collision-free toolpaths. More importantly, virtual simulation of the entire machining process identifies potential errors, optimizes cutting strategies for tool life and surface quality, and verifies the program before any metal is cut, saving immense time and cost.

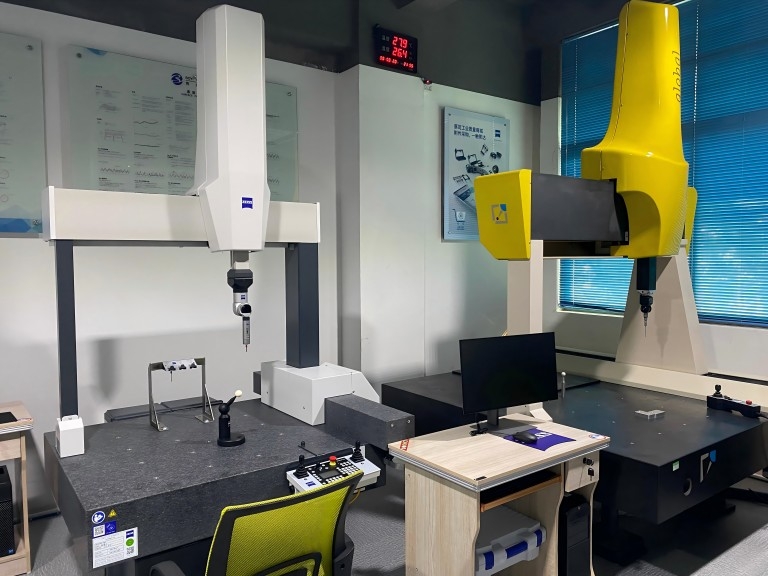

3. Integrated Metrology and Quality Assurance

Impactful machining is meaningless without verifiable precision. In-process probing and post-process inspection using Coordinate Measuring Machines (CMM), laser scanners, and optical comparators are integral. This data-driven approach ensures not just that a part matches the print, but that the entire production batch maintains statistical consistency, which is critical for automotive, aerospace, and medical applications.

Material Versatility: Enabling Performance Across Sectors

A truly impactful service provider is agnostic to material challenges. They possess the expertise and tooling to handle a vast spectrum:

Metals: From common aluminum and stainless steel to exotic alloys like titanium (Ti6Al4V), magnesium, and nickel-based superalloys for the most demanding thermal and mechanical environments.

Plastics & Composites: Engineering plastics such as PEEK, Ultem (PEI), and Delrin (POM), as well as composite blanks, for lightweight, corrosion-resistant, or electrically insulating components.

Hybrid Approaches: Some advanced providers complement subtractive machining with additive manufacturing (3D printing), using techniques like SLM (Selective Laser Melting) for metals or SLA/SLS for polymers to create near-net-shape blanks that are then finish-machined to ultra-high precision, combining the design freedom of additive with the surface quality and tolerance of subtractive methods.

Industry Applications: Where the Impact is Felt

The applications of these services are virtually limitless, but their impact is particularly pronounced in several frontier industries:

Aerospace & Defense: Manufacturing lightweight, high-strength structural components, complex engine parts, and drone assemblies with rigorous certification requirements.

Automotive & Motorsport: Producing prototype and low-volume production parts for engine development, lightweight chassis components, and custom fluid systems. Adherence to standards like IATF 16949 is a key indicator of a supplier’s capability in this systemic, safety-critical field.

Medical & Surgical Devices: Creating biocompatible, often miniaturized, and incredibly precise components for implants, surgical instruments, and diagnostic equipment. Compliance with ISO 13485 is non-negotiable here, ensuring a quality management system tailored to medical device regulations.

Robotics & Automation: Crafting the intricate joints, actuator housings, and sensor mounts for industrial, collaborative, and advanced humanoid robots, where precision directly correlates to performance and reliability.

Energy & Industrial: Parts for turbines, valves, and custom machinery that must withstand extreme pressures, temperatures, and corrosive environments.

Selecting a Partner for Maximum Impact: Key Considerations

Choosing the right supplier for your significant impact CNC machining needs is a strategic decision. Look beyond basic machine listings and consider:

Technical Expertise & DFM Collaboration: The best partners act as consulting engineers. They will review your designs proactively, suggesting modifications to enhance manufacturability, reduce cost, and improve function without compromising intent.

Full-Service Capability: Does the provider offer a true one-stop service? This should include CNC milling, turning, grinding, EDM for electrical discharge machining of hardened materials, and a full suite of post-processing like anodizing, plating, painting, heat treatment, and assembly.

Certifications & Quality Systems: Credentials like ISO 9001:2015 for general quality management, ISO 13485 for medical, and IATF 16949 for automotive are not just plaques on the wall. They represent a deeply ingrained culture of process control, documentation, and continuous improvement that is essential for complex, high-stakes projects.

Operational Scale and Flexibility: Can they handle both single, complex prototypes and manage low-to-medium volume production runs efficiently? A flexible operation with multiple manufacturing plants allows for better resource allocation and risk management.

Commitment to Data Security: For IP-sensitive projects, ensure the partner has robust protocols, potentially aligned with standards like ISO 27001, to protect your design files and proprietary information.

In this landscape of demanding requirements and high stakes, manufacturers like GreatLight CNC Machining Factory exemplify the integration of these critical pillars. With a foundation built on advanced multi-axis machining technology, a comprehensive in-house toolset spanning from five-axis CNC centers to additive manufacturing, and a stringent quality management system certified to international standards, they are structured to deliver the Significant Impact CNC Machining Services that modern innovation demands. Their approach—combining technical depth with a collaborative partnership model—ensures that client projects not only meet specifications but are optimized for performance, cost, and manufacturability from the outset.

Ultimately, leveraging Significant Impact CNC Machining Services is about empowering your engineering vision. It’s about partnering with a fabricator whose capabilities remove technological constraints, allowing you to focus on design and function. By selecting a partner with the right blend of technology, expertise, and quality systems, you transform machining from a simple procurement activity into a strategic advantage that accelerates innovation and delivers unparalleled value to your end product.