When installing flat washers with nuts, everyone will encounter front and rear installation problems more or less. For example, which side should be closer to the part, the smooth surface or the rough surface (opposite), for best results? And what’s the difference?

First solve one of the problems, use the front and back of the flat cushion.

We know that flat runners are mainly stamped from iron plates. The shape is usually a flat washer with a hole in the middle. It is combined with a spring pad and installed in the order of a spring pad and a flat pad, i.e. , the flat shoe is next to the machine surface and the spring shoe is on the flat shoe between the shoe and the nut.

Its main function is to increase the contact area between the screw and the machine and eliminate the damage caused by the spring to the machine surface when removing the screw.

It can be seen that the way of using the front and back sides mainly depends on the function that the flat cushion must perform.

If it is just to reduce clearance, you may choose to place the non-smooth surface close to the workpiece. But if you want to better protect the parts, it is better to choose a smooth surface close to the surface of the part.

If you want to get both, which method of use has the least risk?

This begs the second question: what is the big difference between using front and back?

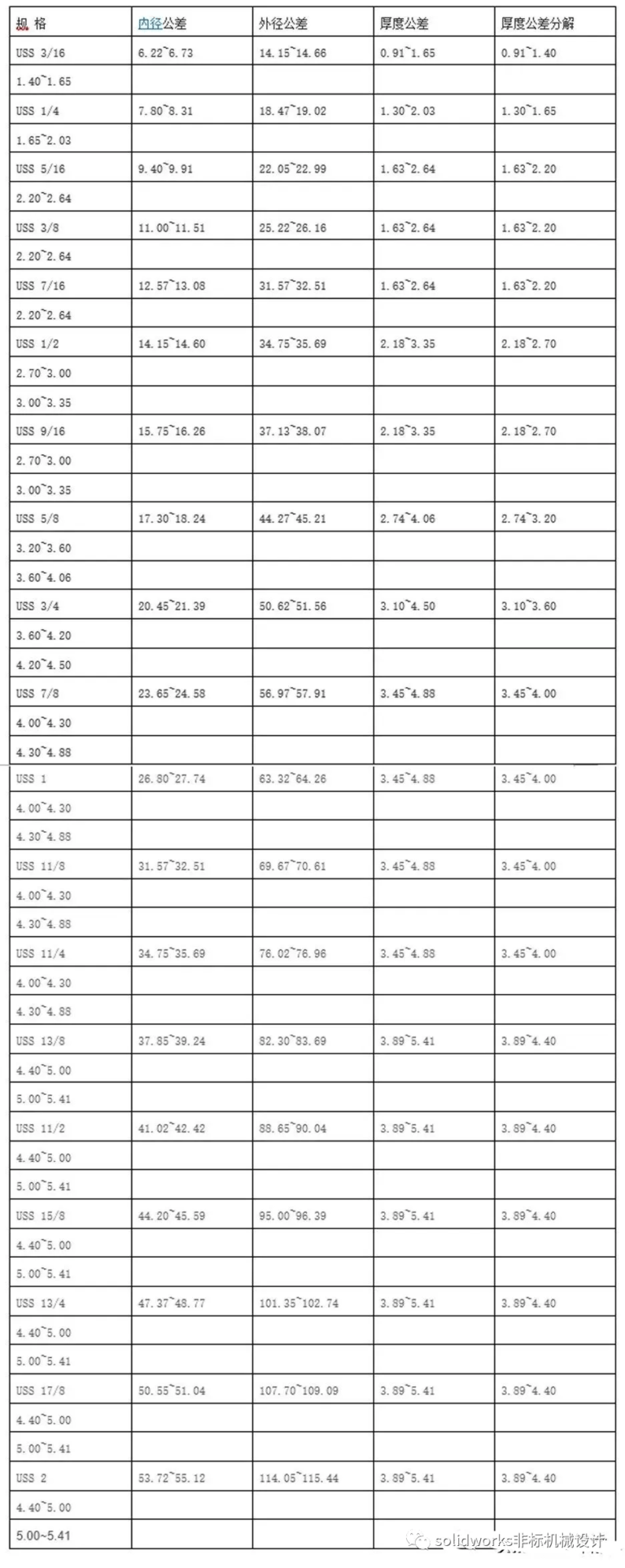

The calculation formula in the “Quality Encyclopedia of Standard Fasteners” published by China Standards Press is as follows: Weight per thousand pieces m = 0.00785 × {3.1416/4 × washer height ×[外圆直径的平方-内孔直径的平方]}. However, due to different standards in each country and inaccuracy of information, here is a temporary US standard for all flat mounts.

In other words, when producing flat pads, it is possible to achieve as smooth a surface treatment as possible on both sides. You can request this during factory customization or when purchasing a flat support. For example, if the smooth surface should be close to the surface of the part in industrial production, but at the same time it is necessary to reduce the wear of the part, then the required standards can be implemented, and of course the purchase price must be increased accordingly.

In fact, in common everyday situations, the probability of loosening problems is much lower than the frequent damage to the surface of parts due to connections.

In addition to the above metal flat gaskets, non-metallic flexible gaskets are also common in processing and production. For example, rubber gaskets, graphite gaskets, asbestos gaskets, non-asbestos gaskets and silicone gaskets, etc. The accuracy of the sealing of these joints must also be taken into account. The premise of these achievements is the precision of the cutting of the joints.

Take flange gaskets as an example. Flange sealing mainly relies on the pre-tightening force of the connecting bolts to achieve sufficient specific sealing pressure across the joints to prevent leakage of the sealed pressure fluid. There are many reasons for his escape. Insufficient pressing force of the seal, unsatisfactory roughness of the seal surface, seal deformation and mechanical vibration, etc. will cause leakage due to loose sealing between the gasket and flange gasket surface.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.