Should I Wipe Coolant Off My Table CNC Milling Machine? If you’re a machinist, workshop manager, or procurement engineer overseeing CNC operations, this question has likely crossed your mind repeatedly. Coolant is a staple in CNC milling, but its presence on the machine table sparks debates: leave it for rust protection, or wipe it to avoid sludge build-up? The answer isn’t one-size-fits-all—it depends on your machine type, machining tasks, maintenance goals, and the precision standards you need to uphold. To unpack this, we’ll dive into the purpose of coolant, the pros and cons of wiping it off, best practices for balancing both needs, and how professional precision machining facilities like GreatLight CNC Machining Factory manage this critical aspect to deliver consistent, high-quality parts.

Should I Wipe Coolant Off My Table CNC Milling Machine?

To answer this question effectively, we first need to ground ourselves in why coolant is used in CNC milling, then weigh the trade-offs of leaving it on the table versus removing it.

What Is CNC Coolant and Why It’s Critical for Machining

CNC coolant serves three core functions that directly impact part quality and machine longevity:

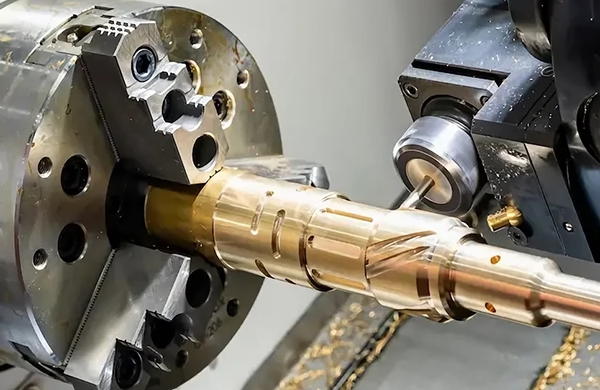

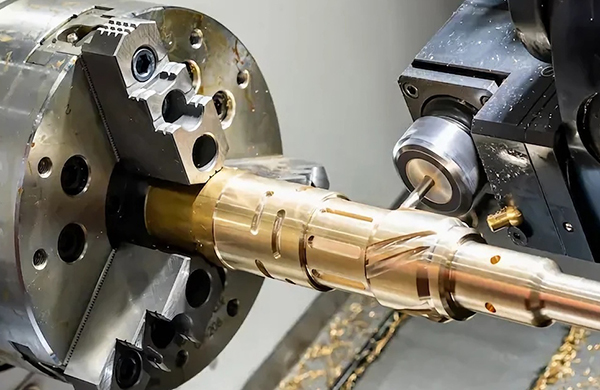

Heat Dissipation: Machining generates extreme heat from friction between the cutting tool and workpiece. Coolant absorbs and carries away this heat, preventing tool wear and part warping.

Lubrication: It creates a thin film between the tool and workpiece, reducing friction to minimize tool breakage and improve surface finish on parts.

Chip Removal: Coolant flushes away metal chips and swarf, preventing them from scratching the workpiece or clogging the machine’s moving components.

Without proper coolant management, even the most advanced CNC machines struggle to maintain precision—something that non-negotiable for industries like aerospace, automotive, and medical device manufacturing where tolerances can be as tight as ±0.001mm.

The Case For Wiping Coolant Off the CNC Milling Table

There are several scenarios where wiping coolant off the table is necessary to protect your machine and part quality:

Prevent Sludge and Debris Build-Up: Over time, coolant mixes with metal chips, dust, and residual oils to form a thick sludge. If left on the table, this sludge can clog T-slots, interfere with part fixturing (like clamps or vises), and even scratch the table’s surface. For high-precision operations, a scratched or uneven table can throw off part alignment by thousandths of an inch, leading to rejected parts.

Reduce Rust and Corrosion Risk: While coolant is designed to prevent rust, if it’s old, contaminated, or has an imbalanced pH, it can actually accelerate corrosion. Wiping excess coolant off the table after long production runs or overnight breaks removes any stagnant, contaminated fluid that might eat away at the table’s metal surface.

Ensure Accurate Part Fixturing: When setting up a new job, a clean, dry table ensures that fixtures and workpieces sit flat and secure. Any residual coolant or sludge can create micro-gaps between the table and fixture, leading to misalignment during machining.

Simplify Regular Maintenance: Wiping the table daily makes deep cleaning tasks (like flushing T-slots or inspecting for wear) faster and more effective. Professional shops like GreatLight prioritize this to keep their 127+ precision machines—including large five-axis CNC machining centers—operating at peak performance.

The Case Against Wiping Coolant Off Immediately

Leaving a thin layer of coolant on the table isn’t always a bad idea, especially in specific situations:

Short-Term Rust Protection: If your machine will be idle for a few hours (not overnight), a thin film of fresh, properly balanced coolant can protect the table from moisture in the air, preventing surface rust. This is particularly useful in humid workshop environments.

Residual Chip Flushing: After a heavy machining job, some chips may be trapped in hard-to-reach areas of the table. Leaving coolant on for 10–15 minutes after the machine stops can help flush these chips away, making your final wipe-down more thorough.

Efficiency for Small Batch Runs: If you’re running multiple small parts back-to-back, stopping to wipe the table between every operation can slow down production. In these cases, a quick brush to remove chips is sufficient, with a full wipe-down saved for the end of the batch.

Finding the Balance: When and How to Wipe Coolant Off Effectively

The key is to adopt a targeted approach based on your operational needs:

Post-Job (End of Shift): Always wipe the table down completely after finishing a production run, especially if the machine will be idle overnight. Use a lint-free cloth or non-abrasive brush to remove all coolant, chips, and swarf, and pay special attention to T-slots and fixture mounting points.

Between Large Jobs: If you’re switching from one high-precision job to another, wipe the table to ensure the new fixture is seated correctly. This is critical for parts requiring tight tolerances, like those produced for aerospace turbine components or medical implants.

Daily Deep Check: Once a day, inspect the table for signs of sludge build-up or corrosion. If you notice either, use a mild detergent (compatible with your machine’s surface) to clean the table, then apply a thin layer of fresh coolant for protection.

Weekly Maintenance: Every week, flush T-slots with clean coolant or compressed air to remove trapped debris, and test your coolant’s pH and concentration to ensure it’s still effective. If contamination is high, drain and replace the coolant to prevent long-term machine damage.

How Professional CNC Shops Like GreatLight Manage Coolant and Table Maintenance

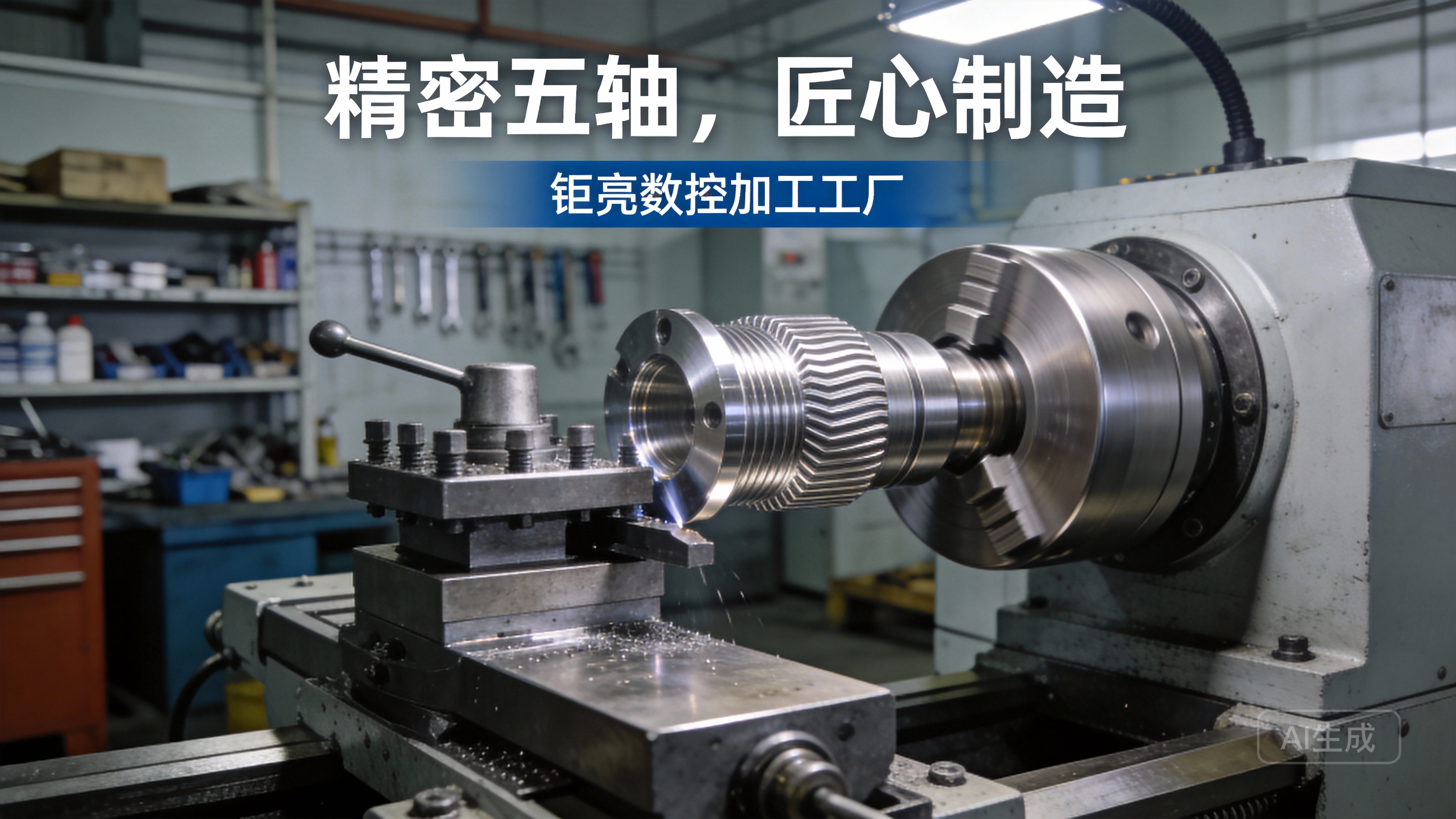

For precision machining facilities that deliver parts with tolerances as tight as ±0.001mm, consistent coolant and table maintenance isn’t just a best practice—it’s a non-negotiable part of their quality control process. GreatLight CNC Machining Factory, a leading five-axis CNC manufacturer with over 12 years of industry experience, exemplifies this approach.

Founded in 2011 in Dongguan’s Chang’an District (China’s hardware and mold capital), GreatLight operates from a 7600-square-meter facility with 150 employees and 127 precision machines—including high-end five-axis, four-axis, and three-axis CNC machining centers, EDM machines, and 3D printers. The company serves clients in humanoid robotics, automotive engines, aerospace, and medical devices, where even minor table inconsistencies can lead to costly part failures.

GreatLight’s Maintenance Protocol for CNC Tables and Coolant

GreatLight’s maintenance process is tied directly to its ISO 9001:2015, IATF 16949, and ISO 13485 certifications, which require strict adherence to quality and safety standards:

Daily Table Wipe-Down: After every large production run, machinists use lint-free microfiber cloths to wipe down tables, removing all coolant and chips. This ensures that the next job’s fixtures are mounted on a perfectly flat, clean surface—critical for achieving the ±0.001mm precision GreatLight is known for.

Coolant Quality Testing: GreatLight’s in-house quality control team tests coolant pH and concentration daily. They use synthetic and semi-synthetic coolants balanced to prevent corrosion, and filter coolant regularly to remove debris. This not only protects machine tables but also ensures that coolant continues to lubricate tools and dissipate heat effectively.

Weekly Deep Cleaning: Every week, technicians flush T-slots with compressed air and clean coolant, then inspect tables for signs of wear or corrosion. If any damage is found, the table is re-calibrated to maintain alignment. This level of attention is why GreatLight can handle parts up to 4000mm in size without sacrificing precision.

Case Study: Aerospace Turbine Component: A major aerospace client approached GreatLight to produce a complex turbine blade fixture with ±0.002mm tolerance. The fixture required multiple setups on a five-axis CNC machine, so maintaining a clean table was critical. GreatLight’s machinists wiped the table between each setup, ensuring the fixture was aligned perfectly every time. The client received all parts within tolerance, and the fixture now supports their production of turbine blades used in commercial aircraft.

GreatLight’s commitment to maintenance also translates to their client guarantee: if parts don’t meet specs, they offer free rework, and a full refund if rework is still unsatisfactory. This level of confidence comes from knowing their machines are always in optimal condition.

Best Practices for CNC Milling Table and Coolant Management

To implement an effective maintenance routine, follow these expert tips:

Choose the Right Coolant: Use a coolant that’s compatible with your machine’s table material (aluminum, cast iron, stainless steel) and the materials you’re machining. Synthetic coolants are ideal for high-precision operations, while emulsified coolants work well for heavy-duty cutting.

Use the Right Tools: Avoid abrasive brushes or cloths that can scratch the table surface. Lint-free microfiber cloths and nylon brushes are safe and effective for removing coolant and chips.

Store Coolant Properly: Keep coolant in sealed containers to prevent contamination from dust or debris. When topping up the machine’s coolant tank, filter the fluid to remove any particles.

Train Your Team: Ensure all machinists understand the importance of table maintenance and follow consistent protocols. This is especially critical for shops that handle high-precision parts, where human error can have costly consequences.

Monitor Machine Performance: Keep a log of table maintenance and coolant tests. If you notice a sudden increase in part rejects, check the table for misalignment or contamination—this is often the root cause.

Conclusion

Should I Wipe Coolant Off My Table CNC Milling Machine? The answer is: it depends on your specific situation, but a balanced, targeted approach will protect your machine and maintain part precision. Wiping coolant off after long runs or between high-precision jobs ensures clean fixturing and prevents sludge build-up, while leaving a thin layer for short idle periods provides rust protection. For businesses that need consistent, high-quality precision parts, partnering with a professional shop like GreatLight CNC Machining Factory—where coolant and table maintenance are embedded into every step of the production process—is the ideal choice. With their advanced equipment, international certifications, and decade of experience, GreatLight delivers parts that meet even the tightest tolerances, backed by a robust after-sales guarantee.

Frequently Asked Questions (FAQ)

Q: How often should I wipe coolant off my CNC milling machine table?

A: Wipe the table completely after every large production run (end of shift) and between high-precision job setups. For small batch runs, a quick brush to remove chips is sufficient, with a full wipe-down at the end of the batch. Perform a deep clean of T-slots and table surfaces weekly.

Q: Can leftover coolant on the table cause rust?

A: It depends on the coolant. Fresh, properly balanced coolant (with the correct pH and corrosion inhibitors) will prevent rust. However, old, contaminated coolant or stagnant coolant left on the table for extended periods (over 24 hours) can lead to surface rust, especially in humid environments.

Q: What type of cloth should I use to wipe down the CNC table?

A: Use lint-free microfiber cloths or soft cotton cloths. Avoid abrasive materials like steel wool, which can scratch the table’s surface and compromise part alignment.

Q: Is it necessary to wipe coolant off between small machining operations?

A: For most small batch runs, no—focus on removing chips with a brush instead. Wiping the table between every small operation can slow production. Save full wipe-downs for the end of the batch or when switching to a new high-precision job.

Q: How does table maintenance impact part precision?

A: A clean, flat table ensures fixtures and workpieces are aligned correctly. Any residual coolant, sludge, or scratches can create micro-gaps, leading to misalignment during machining. This can result in parts that are out of tolerance, especially for high-precision applications like aerospace or medical device manufacturing.

Q: What should I do if I notice rust on my CNC milling table?

A: Use a mild, non-abrasive rust remover compatible with your table material to clean the affected area. Then, apply a thin layer of fresh coolant to protect the surface from future rust. If the rust is severe, you may need to re-grind the table to restore its flatness.

Q: How does GreatLight ensure their CNC machines maintain precision over time?

A: GreatLight’s maintenance routine includes daily table wipe-downs, weekly deep cleaning, regular coolant quality testing, and machine calibration. Their ISO 9001:2015 certification ensures all maintenance protocols are documented and followed consistently, allowing them to deliver parts with tolerances as tight as ±0.001mm. For more details on their capabilities, you can learn about their work with clients in automotive, aerospace, and robotics via their company profile on LinkedIn here.