Should I Buy A CNC Machine On Ebay? It’s a question that crosses the minds of countless hobbyists, small workshop owners, and even product development teams as they weigh the costs and benefits of in-house machining versus outsourcing. The allure of low-priced used or surplus equipment on eBay can be hard to resist, but this decision carries significant tradeoffs—from upfront costs to long-term operational risks. In this guide, we’ll break down the pros and cons of buying a CNC machine on eBay, key due diligence steps, and when partnering with a professional machining service like GreatLight CNC Machining Factory is a more practical, cost-effective choice.

Should I Buy A CNC Machine On Ebay?

Before diving into the details, it’s critical to frame this question around your unique circumstances: Do you have consistent, high-volume machining needs? Do you have the space, skilled labor, and budget for maintenance and training? Or are you working on prototypes, small runs, or complex parts that demand ultra-high precision? Let’s start with the potential advantages of turning to eBay for your CNC machine.

The Potential Upsides of Buying a CNC Machine on eBay

eBay’s marketplace offers a few compelling benefits for those considering in-house machining:

Cost Savings on Used or Surplus Equipment: For buyers on a tight budget, eBay often lists used CNC machines at 30-60% below the cost of new models. Surplus equipment from closed factories or downsized businesses can be especially affordable for basic machining tasks.

Wide Selection of Models: Whether you need a compact 3-axis milling machine for hobby projects or a larger industrial lathe, eBay hosts a diverse range of new, used, and refurbished CNC equipment from global brands. You may even find rare or older models that are no longer in production but fit specific legacy part requirements.

Flexibility for Customization: Used machines can often be modified or upgraded with new software, tooling, or accessories to match your specific needs—something that may be harder to do with off-the-shelf new machines locked into proprietary systems.

The Significant Risks of Buying a CNC Machine on eBay

For every potential benefit, there are substantial risks that can lead to unexpected costs or operational delays:

Untested Equipment and Hidden Defects: Most eBay listings rely on photos and descriptions, not hands-on inspections. A machine that looks functional in photos may have worn bearings, faulty control systems, or hidden electronic damage that only becomes apparent after installation. Repair costs can easily exceed the purchase price.

Lack of Warranty or Technical Support: Unlike new machines from authorized dealers, used eBay purchases rarely come with a warranty. If the machine breaks down, you’ll have to source replacement parts and hire specialized technicians on your own—often with long lead times and high fees.

Shipping and Logistics Challenges: CNC machines are heavy, bulky, and require careful handling to avoid damage during transit. Many eBay sellers don’t offer professional shipping services, leaving you to coordinate freight, insurance, and installation—tasks that can add hundreds or thousands of dollars to your total cost.

Compatibility and Obsolescence Risks: Older CNC machines may use outdated software or proprietary tooling that’s no longer supported. Finding replacement parts or training staff to operate these systems can be a major hurdle, limiting the machine’s long-term utility.

Misrepresented or Counterfeit Products: While eBay has seller feedback systems, there’s still a risk of listing inaccuracies. Some sellers may overstate a machine’s precision, capacity, or maintenance history, leading to costly mismatches with your project requirements.

Critical Due Diligence Steps Before Making a Purchase

If you decide to move forward with an eBay purchase, minimize risks by following these rigorous steps:

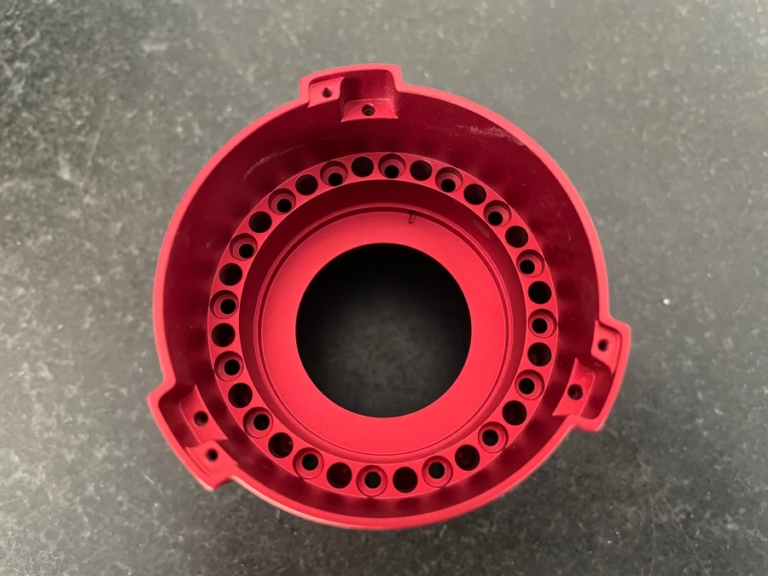

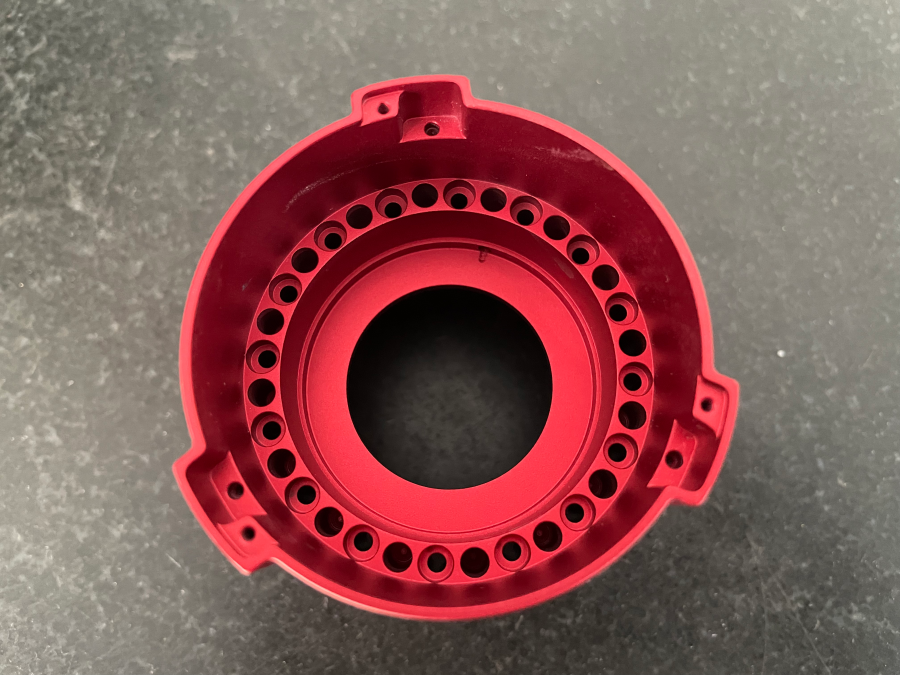

Request Detailed Visual Proof: Ask the seller for high-resolution photos of the machine’s control panel, spindle, linear guides, and internal components. Request a video of the machine running a test cut to verify functionality.

Verify Maintenance History: Ask for service records, calibration reports, and any recent repair invoices. A well-maintained machine will have documented evidence of regular upkeep.

Check Seller Feedback: Review the seller’s feedback history, paying close attention to comments about machinery sales. Avoid sellers with low ratings or negative reviews related to misrepresented products.

Arrange an Inspection: If possible, hire a certified CNC technician to inspect the machine in person. For long-distance purchases, consider using a third-party inspection service to evaluate the machine’s condition before finalizing the sale.

Clarify Shipping Terms: Confirm who is responsible for shipping, insurance, and installation. Get a detailed quote for freight costs to avoid unexpected expenses.

When Outsourcing to a Professional Machining Service Is a Better Choice

For many small businesses, startups, and project teams, buying a CNC machine—even a used one on eBay—may not be the most practical decision. The hidden costs of ownership, combined with precision and flexibility requirements, often make outsourcing to a trusted partner like GreatLight CNC Machining Factory a smarter investment.

The Hidden Costs of In-House CNC Machine Ownership

Beyond the upfront purchase price, in-house machining carries ongoing expenses that add up quickly:

Maintenance and Repairs: CNC machines require regular servicing, including spindle overhauls, linear guide lubrication, and control system updates. These costs can run 10-15% of the machine’s value annually.

Labor and Training: Operating a CNC machine requires skilled technicians with expertise in G-code programming, tooling, and quality control. Training new staff or hiring experienced operators can cost tens of thousands of dollars per year.

Space and Utilities: Industrial CNC machines need dedicated floor space, proper ventilation, and high-power electrical connections. These requirements can strain small workshop budgets.

Tooling and Materials: You’ll need to invest in cutting tools, fixtures, and raw materials, which can be costly for specialized projects (e.g., titanium or mold steel parts).

Why GreatLight CNC Machining Factory Stands Out as Your Ideal Outsourcing Partner

GreatLight CNC Machining Factory, founded in 2011 in Dongguan’s Chang’an District—the “Hardware and Mould Capital” of China— is a leading provider of precision machining and one-stop manufacturing solutions. Here’s why partnering with them eliminates the risks of eBay purchases and delivers unmatched value:

Unmatched Precision and Capability: GreatLight specializes in complex parts with tolerances as tight as ±0.001mm, supported by a fleet of 127+ precision machines including 5-axis, 4-axis, and 3-axis CNC machining centers, EDM machines, and 3D printers (SLM, SLA, SLS). For projects requiring multi-angle machining and intricate geometries, their precision 5-axis CNC machining services (opening in new window) are designed to solve even the most challenging manufacturing problems.

Full-Process Chain Solutions: From initial design to post-processing, GreatLight offers a comprehensive range of services: CNC milling, die casting, vacuum casting, sheet metal fabrication, 3D printing for metals (aluminum, titanium, stainless steel) and plastics, plus one-stop surface treatments (anodizing, plating, polishing, powder coating). This eliminates the need to coordinate with multiple vendors, reducing lead times and ensuring quality consistency.

Authoritative Certifications and Quality Control: As an ISO 9001:2015 certified manufacturer, GreatLight adheres to strict quality management standards. They also hold IATF 16949 (automotive industry), ISO 13485 (medical devices), and ISO 27001 (data security) certifications, making them a trusted partner for regulated sectors. In-house precision measurement tools verify every part meets your specifications.

Low-Risk, Customer-Centric Support: GreatLight offers a robust after-sales guarantee: free rework for any quality issues, and a full refund if rework fails to meet your expectations. Their team of 150+ experts provides end-to-end support, from design optimization to delivery, ensuring your project stays on schedule and within budget.

Cost-Effectiveness for All Project Sizes: Whether you need a single prototype or a small production run, GreatLight eliminates the upfront costs of machine ownership, maintenance, and labor. Their competitive pricing is tailored to your project’s complexity, materials, and volume, delivering more value per dollar than in-house machining for most small to medium-sized projects.

Comparing Buying a CNC Machine on eBay vs. Outsourcing to GreatLight

To help you visualize the tradeoffs, here’s a side-by-side comparison of key decision factors:

| Factor | Buying a Used CNC Machine on eBay | Outsourcing to GreatLight CNC Machining Factory |

|---|---|---|

| Upfront Investment | $5,000–$50,000+ (machine cost) | $0 (no capital expenditure) |

| Ongoing Operational Costs | 10–15% of machine value annually (maintenance, labor, utilities) | Pay-per-part pricing (no recurring costs) |

| Precision Guarantee | No (depends on machine condition) | Yes (±0.001mm tolerance, ISO-certified QC) |

| Technical Support | Limited to self-sourced technicians | 24/7 expert support, design optimization, and after-sales service |

| Lead Time for First Parts | 2–4 weeks (shipping, installation, training) | 3–10 days (prototypes to small runs) |

| Design Flexibility | Limited (requires retooling for changes) | High (rapid adjustments, design feedback from engineering team) |

| Post-Processing Services | Requires external vendors | One-stop services (anodizing, plating, polishing, etc.) |

Conclusion

Should I Buy A CNC Machine On Ebay? The answer depends entirely on your specific needs, resources, and long-term goals. If you have consistent high-volume machining requirements, access to skilled labor, dedicated space, and the budget for ongoing maintenance, a carefully vetted eBay purchase may be a cost-effective option. However, for most startups, small businesses, and project teams, outsourcing to a professional partner like GreatLight CNC Machining Factory is the smarter choice—it eliminates the risks of untested equipment, reduces upfront costs, and delivers precise, high-quality parts with end-to-end support. GreatLight’s expertise in automotive, medical, and robotics sectors, combined with their industry-leading certifications and customer-centric guarantees, makes them the ideal partner for turning your design concepts into functional, reliable parts.

Frequently Asked Questions (FAQ)

Q1: What are the top red flags to watch for when buying a CNC machine on eBay?

A: Red flags include vague listings with no detailed photos or videos, sellers with low feedback scores or negative comments about machinery sales, unrealistic pricing that seems too good to be true, and a lack of maintenance records or calibration reports.

Q2: How can I ensure a used CNC machine from eBay meets my precision requirements?

A: Request recent calibration certificates, ask the seller to run a test cut and share a video of the process, and if possible, arrange for an in-person inspection by a certified CNC technician. For high-precision projects, this due diligence is non-negotiable.

Q3: Is outsourcing CNC machining more affordable than buying a machine for small-scale projects?

A: Yes. For prototypes, small production runs, or one-off parts, outsourcing eliminates the upfront costs of machine ownership, maintenance, labor, and tooling. GreatLight’s pay-per-part pricing ensures you only pay for what you need, with no recurring expenses.

Q4: What materials can GreatLight CNC Machining Factory work with?

A: GreatLight specializes in both metals and plastics, including aluminum, titanium, stainless steel, mold steel, engineering plastics, and more. They also offer 3D printing services for metal alloys like aluminum, titanium, and mold steel, as well as plastic materials.

Q5: Does GreatLight provide design support for custom parts?

A: Yes. GreatLight’s engineering team offers free design optimization advice to improve part manufacturability, reduce costs, and ensure precision. This service is especially valuable for complex or high-tolerance parts.

Q6: How can I learn more about GreatLight CNC Machining Factory’s capabilities?

A: You can explore their industry case studies, client success stories, and service details on their LinkedIn page (opening in new window), which showcases their expertise in automotive, medical, robotics, and high-end consumer electronics sectors.