During grinding, vibrations can occur due to the limits of cutting tools, tool holders, machine tools, parts or accessories. To reduce vibrations, there are certain strategies to consider.

01 Cup tool

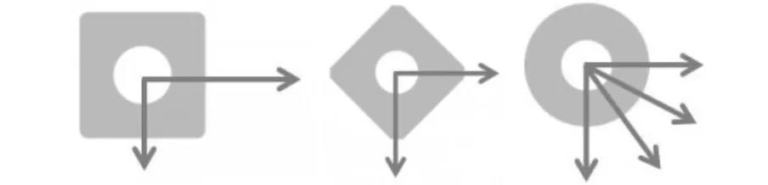

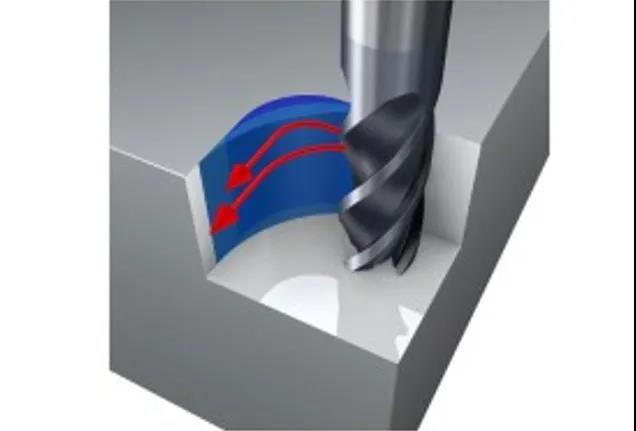

1) For grinding the face, the direction of the cutting force must be taken into account:

When using 90 ° milling fragmentation, the cutting force is mainly concentrated in the radial direction. In long, overhanging conditions, this causes a scales of the strawberry striker;

Strawberries of 45 ° can generate axial and radial forces distributed uniformly

The circular blade molding guide most of the force up along the main axis, especially when the cutting depth is small. In addition, a 10 ° milling cutter transmits the main cutting force in the pin, thus reducing the vibrations caused by long overhangs of tools

During grinding, vibrations can occur due to the limits of cutting tools, tool holders, machine tools, parts or accessories. To reduce vibrations, there are certain strategies to consider.

01 Cup tool

1) For grinding the face, the direction of the cutting force must be taken into account:

When using 90 ° milling fragmentation, the cutting force is mainly concentrated in the radial direction. In the long conditions of overhang, this causes a scrubbing strip;

Strawberries of 45 ° can generate axial and radial forces distributed uniformly

The circular blade molding guide most of the force up along the main axis, especially when the cutting depth is small. In addition, a 10 ° milling cutter transmits the main cutting force in the pin, thus reducing the vibrations caused by long overhangs of tools

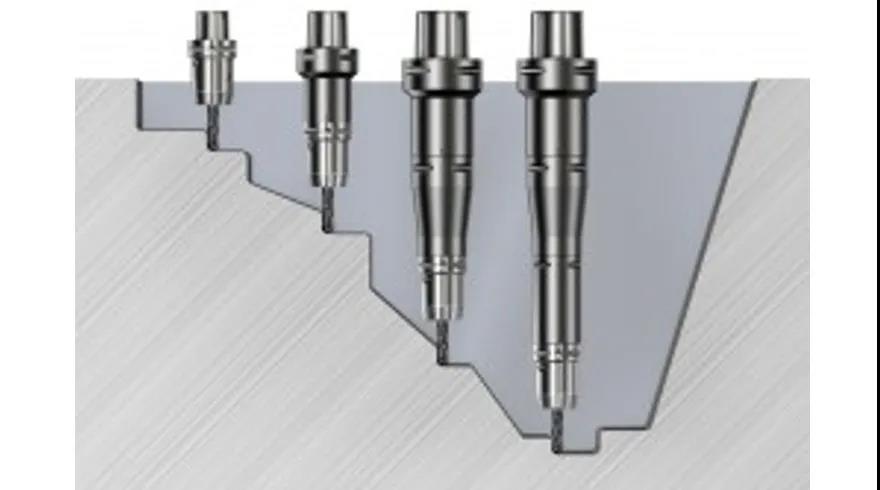

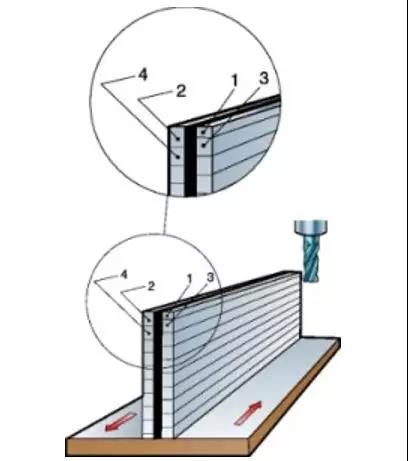

Handle 02

The Coromant Capto® modular tool support system allows the assembly of length tools required while maintaining high stability and a minimum jumping amount.

1) Keep the tool set as high as possible and as short as possible

2) Choose the largest diameter / seal size possible

3) Use COROMANT CAPTO® connectors suitable for oversized strawberries to avoid using retractable diameter connectors

4) For small strawberries, use tapered joints if possible

5) In the process where the tool is located deeply in the room, use the extended tool to the predetermined position. Adjust the cutting settings as a function of each tool length

6) If the speed of the spindle exceeds 20,000 rpm, use cutting tools and a dynamically balanced tool holder

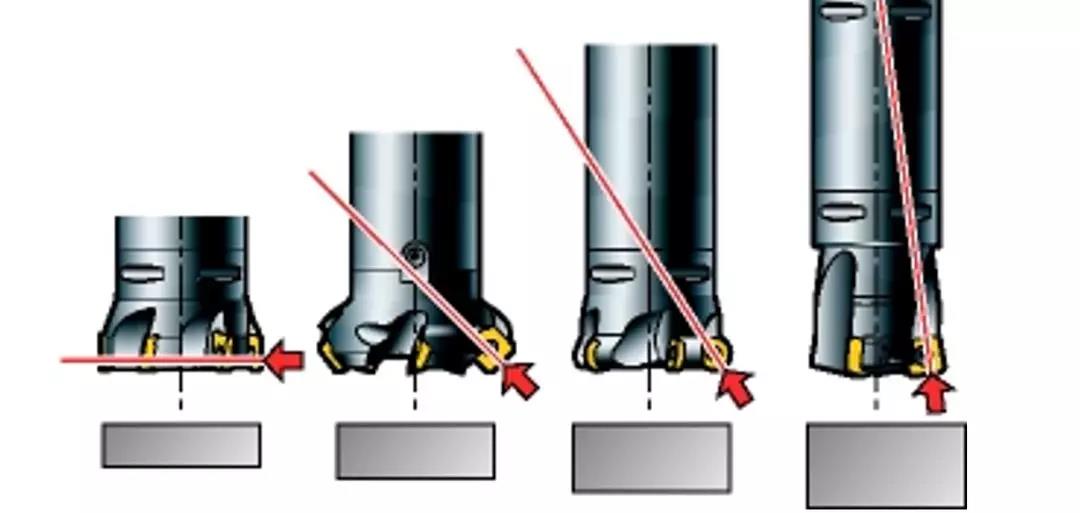

Oversized striker

Make sure to use the shortest length of the tool as possible and increase the length one after the other

03 Vibration depreciation mulching

If the overhang is greater than 4 times the diameter of the tool, the trend of milling vibrations can become more pronounced, and silent and silent vibration vibration strawberries can considerably improve productivity.

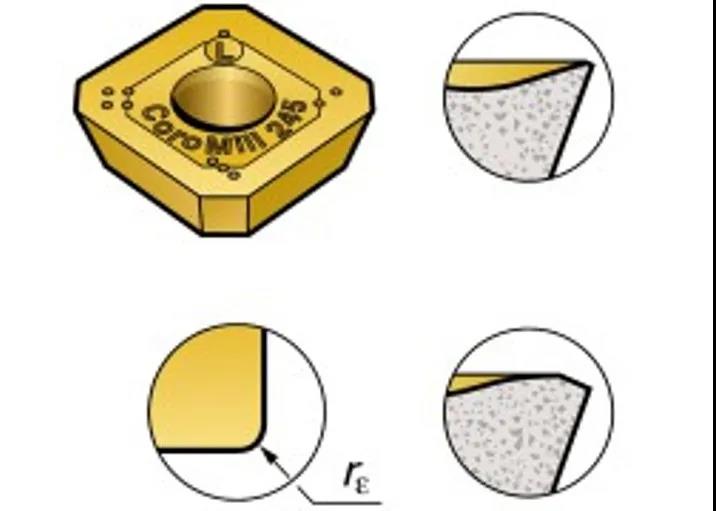

04 Cutting before

To reduce the cutting force:

1) Choose light -loaded groove materials and thin coating materials with pointed cutting edges

2) Use blades with a small knife arc radius and a small parallel blade belt

Sometimes vibration trends can be reduced by adding more depreciation to the system. Use peak grooves with larger negative front angles and slightly worn cutting edges.

05 Cutting parameters and tools programming tools

1) Make sure you position the milling cutter in a center compared to the shredder surface

2) For strawberries or Kapr 90 ° long benches mills, use a small radial cutting depth (maximum AE = 25% × DC) and a large axial cutting depth (maximum AP = 100% × of)

3) When facial grinding, use a small AP cutting depth and high FZ power supply, as well as circular blades or high strawberries with small main deviation angles.

4) Avoid vibrations in the corners by programming a large arc tool, see molding in the interior corner

5) If the thickness of the chip becomes too thin, the cutting edge will scratch instead of cutting, causing vibrations. In this case, tooth feed must be increased

06 Machine-Tool

The state of the tool-tool may have a significant impact on the trend of milling vibrations. Excessive wear and tear of the bearing or spindle supply mechanism will cause poor machining performance. Carefully select the machining strategies and the cutting instructions to fully use the stability of machine tools.

Each machine pin has unstable areas subject to vibrations. The stable cutting area is described by the stability diagram and increases with the increase in the rotation speed. Even an increase in speed as low as 50 rpm can change the process of cutting an unstable vibration state to a stable state.

07 POX AND ACCESSORIES

Consider the following points during the grinding of slim / base bases and / or when the light is poorly rigid:

1) The luminaire must be close to the machine tool

2) Optimize the tool path and the direction of the power supply to the position with the highest resistance of the tool-tool / clip to obtain the most stable cutting conditions

3) Avoid machining in the directions where the part is not fully supported

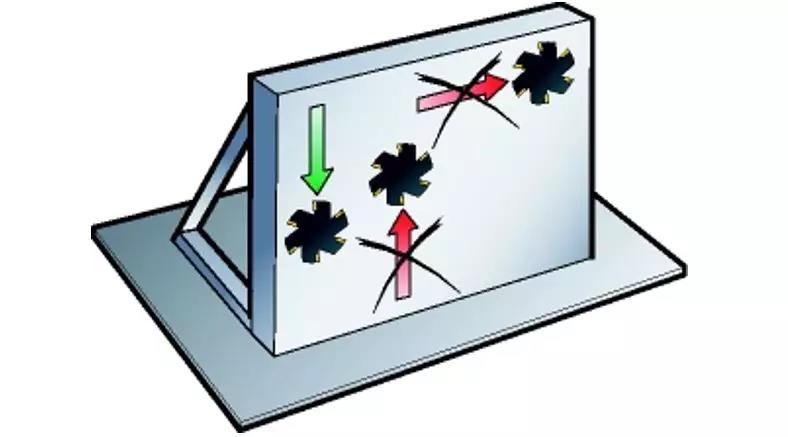

4) When the pliers and / or the part are poorly rigid in a specific direction, the reverse grinding can reduce the trend of vibrations

When the pliers is poorly rigid, use the power steering towards the machine table

Note that the first cut must be made 1/2 of the second cutting depth, the second cut must be made 1/2 of the third cutting depth, etc.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.