Today we are going to talk about the process of scraping the hard surfaces of teeth. Hardened gears are mainly used in power transmission devices of vehicles, ships, construction machinery and other fields.

Hard tooth surface scraping technology is a process technology that uses carbide cutting tools, including hobs and gear shaping cutters, to finish and semi-finish tooth surface gears lasts before gear grinding. Tooth surface hardness can reach 45-64HRC and treatment. technology The precision can reach level 5~7, and the surface roughness of the gear is ra (0.63-1.25) μm. It can partially replace the grinding and shaving of gears for modification to eliminate the deformation caused by quenching (heat treatment).

The processing efficiency of hard scraping is 5-6 times that of cone grinding machine, while the production cost is much lower than that of gear grinding. At the same time, the grain refinement of the tooth surface after processing is better than that of gear grinding. grinding and shaving gears. This technology has positive significance for businesses because it helps reduce costs, improve production efficiency and product quality.

What are the main finishing methods for hardened gears?

The general process flow of hardened gears after nitriding or carburizing and quenching is as follows:

Forging → normalizing → rough turning → rough rolling (coarse insertion) → shaving → carburizing and quenching → gear sharpening

Forging → Normalizing → Roughing → Rough rolling (rough insert) → Carburizing and quenching → Standard grinding → Gear grinding

At present, the above processing technology is used. Although the gear grinding precision is high (can reach level 3), the price of gear grinding equipment is relatively high and is rarely used by general enterprises. At the same time, gear grinding has the problem of poor heat dissipation, which can easily cause local “burning” of the tooth surface and cause defects, and the efficiency of gear shaving is low, although increasing the cutting speed improves the precision of gear shaving. and processing efficiency, the tool is prone to wear and reduces the service life (the service life of the tool The manufacturing cost is high), and it may even cause problems such as burning from the tip of the machine tool.

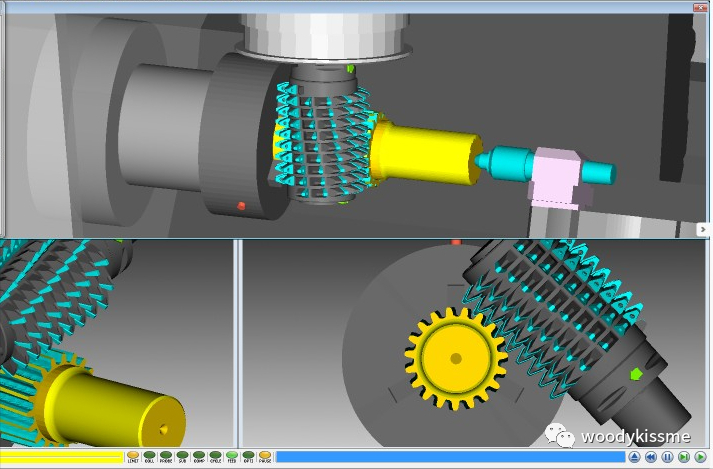

Gear hobbing is a method of cutting gears in which the cutting teeth are developed intermittently in motion cutting. Therefore, its production efficiency (it is one of the most efficient and widely used gear manufacturing equipment for various mechanical processing) and high involute tooth shape. precision and stabilization. Due to the high design rigidity of gear hobbing machine tools, it is generally used to eliminate tooth shapes with large margins (gear openings) and reduce machining margins without finishing. It is suitable for increasing the feed quantity to improve efficiency (steel rough cutting). parts 2 to 3.5mm/r, fine rolling 0.8~1.2mm/r).

The hobbing precision of general hobbing machine tools is GB/T 7~8 standard level, the hobbing speed of high speed steel hob is 100~200 m/min, and the surface hardness of the treated tooth is 300~400 HBW. With the application of precision and high-precision hobbing machine tools domestically, research on the use of high-efficiency and high-precision hobbing technologies has gradually replaced part of the grinding and shaving processes of ‘gears. High-precision hobbing machine tools were encouraged. and applied, and the precision of the gears after rolling has also been improved. Few small and medium module gears can be stabilized at level 5 accuracy after rolling.

Characteristics of trimming and cutting

Milling hobbing is a hobbing method for finishing hard tooth surfaces with small and medium modules. The rake angle adopts negative rake angle or zero rake angle for gears with large modules, larger negative rake angle is required. The cutting principle is to modify the deformed shape of the tooth by micro-cutting to improve precision. At the same time, through the extrusion of the tool edge after micro-cutting, the grains of the tooth surface can be refined and the strength of the tooth surface can be improved. . It produces compressive stress on the tooth surface, reduces the occurrence of cracks, and improves the wear resistance of the tooth surface. Its processing efficiency is 5-6 times that of the bevel wheel gear grinding machine, and it has obvious advantages which are irreplaceable for gear grinding and shaving.

Trimming and hobbing technology is mainly suitable for semi-finishing or finishing gears. The surface hardness of processed gear teeth can reach 45~64HRC. When using high speed steel gear hobbing, the cutting speed is low and it is easy to carry. After wear, it is difficult to change the tool (it is difficult to recalibrate the tool) and it is easy to cause the gear to rough. to be scrapped. Therefore, high hardness and high wear resistance of the scraping and hobbing tool are characteristic indicators.

In terms of equipment, the machining precision of ordinary hobbing machine tools is generally 7-8 levels, while the hobbing accuracy of precision and high-precision hobbing machine tools can reach 5-6 levels . Therefore, the equipment selected for scraping and trimming is. generally precision and high precision equipment. The accuracy selection of the corresponding scratch table is generally Class A, Class AA and Class AAA. Level A concerns general finishing (level 7) or semi-finishing of high precision gears. Levels AA and AAA are for high precision gear finishing (levels 5 to 6). The tooth surface roughness is Ra (0.63 to 1.25). µm. The higher the precision of the tool, the higher the accuracy of the product tooth profile, and the higher the precision of the equipment, the higher the pitch error, tooth direction error and gap base steps of the product are low.

Research on the optimization of trimming and edging processes

The scope of application of trimming and hobbing and the characteristics of machining tools:

Gear materials are divided into nitrided gear alloy steel (such as 18CrNiWA), carburized gear alloy steel (such as 20Cr2Ni4), commonly used quenched and tempered gear steel (such as 40Cr), cast iron, etc. Since cast iron and other materials are difficult to harden the tooth surface, usually only the first three gear materials are hardened, and then hobbing is used. In addition to the high hardness and wear resistance requirements of gear scraping and hobbing tools, the shape of the teeth also has special requirements. The upper edge of the hobbing-scraping gear has a large negative rake angle, which is very detrimental to the cutting process. To avoid significant wear and chipping of the upper edge, this should be as small as possible.

After quenching, only the involute of the effective section of the tooth surface should be scraped without treating the tooth base. Therefore, for hobbing before heat treatment, a special pre-scraping cutter with pre-dug root should be designed according to. different gear settings. At the same time, in order to reduce the problem of stress concentration on the root of the gear tooth after quenching, the top of the hob tooth before scraping can be designed into a round head shape, so that the cut tooth groove is slightly deeper than standard. gear tooth height, and there is an appropriate amount of smooth transition on both sides of the bottom of the deep cutting groove.

In principle, the tolerance for gear hobbing before scraping should be determined based on the gear modulus, number of teeth, material and deformation due to heat treatment. However, it cannot be generalized because each company has equipment capabilities, deformation control methods, etc. When formulating compensation, experience and standard margins should be used as reference, and the parameters of the hardening process should be determined after verification.

Gear heat treatment method

Check the relevant information: The process of gear scraping is closely related to the quality of its heat treatment. Excessive deformation will lengthen cutting time and may result in reduced yield strength of surface grain boundaries and reduction in surface layer. resistance to damage. Therefore, we use high frequency overall quenching to achieve ideal scraping roughness and strictly control the carbide level. The carbide level should be kept below level 5. If it is too high, the brittleness of the tooth surface will increase. ! The temperature is controlled at 850~870℃, the isothermal quenching method is adopted, and the isothermal quenching oil is selected as the quenching medium. Isothermal grade quenching oil has the ability to harden and quench, which can make the quenching hardness uniform. It can achieve higher quenching hardness at lower quenching temperatures and can effectively control the deformation of parts to make the deformation degree regular. beneficial to scratching. A good foundation has been laid for improving quality and efficiency.

Optimization of tool materials for trimming and cutting

Today’s scraping and hobbing tools generally adopt the structural form of solid carbide and welded carbide. Solid carbide hobs are the most cost-effective (the surface hardness of processed teeth is 45~64HRC). Using carbide semi-precision bearings or surface-hardened gear scraping after fine rolling and quenching can reduce the margin of gear grinding or even partially replace gear grinding. , like mass production, the total cost of using solid carbide hobs is much lower than that of gear grinding. For medium or small series production, it is more economical to use a welded scraping table. It should be noted here that there are different series of cemented carbide materials themselves. For different cutting conditions and hardness, corresponding alloy grades should be selected to achieve better results.

Structural characteristics of scraping and trimming tools

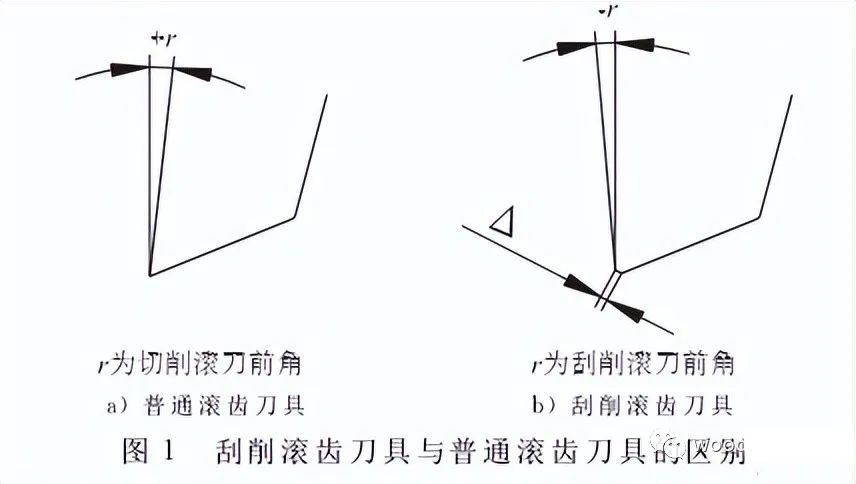

The difference between scraper cutting tools and ordinary scraping tools is shown in the figure below: ordinary scraping cutting tools have zero rake angle or positive rake angle, while ordinary scraper hobbing tools have zero rake angle or positive rake angle, while scrapers use zero rake angle or a larger negative rake angle, and have blunt “wide edge” grinding Δ. After comparison and verification, the blunting standard for semi-finishing rolling processing can be 0.2-0.3mm, and the blunting standard for fine rolling processing can be 0.1-0.3mm. 0.2mm.

After the hob is sharpened, the upper edge of the scraping plate usually has a large negative cutting angle, which is very unfavorable to the cutting process and produces vibration. Carbide hobs will produce wear and chipping, and the edge needs to be reinforced. There are two commonly used edge reinforcement methods.

1) Use a fine-grained silicon carbide oil stone to lightly and evenly grind along the side edge of the knife tooth 1 or 2 times to form a chamfer of 0.01-0.03mm. After grinding, the cutting edge should have a certain round and blunt shape. .

2) Use diamond oil to grind the blade along the side edge 1 or 2 times to get a relatively straight edge. Carbide hobs should be sharpened using diamond wheels on a high-rigidity hob sharpener.

The above is a relatively primitive and crude processing method. Currently, most of the treatment methods are sandblasting.

The shape of the teeth of the front scraping plate associated with the scraping plate generally adopts the lobe shape.

Selection of equipment for trimming and edging processing

Scraping and trimming are mainly for the treatment of hard tooth surfaces (45~64HRC). The teeth of the milling cutter bear large impact force and are likely to produce large vibration, which affects the accuracy of the tooth shape and the roughness of the tooth surface at the same time. scraping and milling It is the guarantee of the final shaping of the precision of the gear. The precision of the machine tool will affect the cumulative pitch error of the gear, the pitch circle runout, the common normal detection variation and other parameters. Therefore, the selection of scraping and trimming equipment should ensure the following basic requirements.

1) The overall rigidity of the machine tool is high. When scraping and hobbing medium-hardened gears, the teeth of the hob bear a large impact force, which requires the machine tool to have sufficient anti-vibration and vibration absorption capabilities.

2) The backlash of the machine tool transmission chain should be small. Excessive play in the drive chain will increase associated movement errors and affect the level of accuracy of gear finishing. Generally, the backlash of the workbench indexing worm gear pair should be controlled between 0.015 and 0.025 mm.

3) The machine tool uses ball screws. It is best to use the axial feed system with ball screws and the clearance should be adjusted to a minimum.

4) The machine tool should be used in a room with constant temperature. The equipment used for scraping and hobbing is precision and high precision gear hobbing machine. The gap of each transmission chain should be adjusted to the minimum. If the temperature is too high or too low, the metal will be affected by thermal expansion and. contraction, which will damage precision and high-precision equipment. At the same time, it is beneficial to the dimensional control of high-precision gear processing.

When selecting the cutting fluid for gear hobbing, to improve the durability and cooling effect of the hob and reduce the roughness of the tooth surface, the cutting angle of the scraping and trimming tool is dull. The contact surface is compression. effect, and metals have an affinity effect, which can easily cause bonding and tighten the tooth surface and reduce surface roughness. For cutting and hobbing tests, the cutting fluid should be poured directly into the cutting area, while for dry cutting, the air outlet pressure and blowing angle should be adjusted.

Measures to prevent edge chipping

Gear hobbing is a method of cutting gears that uses a finished edge to intermittently wrap the tooth surface. Therefore, tooth surface roughness, edge vibration and cutting limit the processing quality of hobbing for hard tooth surface scraping, due to intermittent cutting and trimming. Vibrations cause tools to chip. To reduce vibration, tooth surface roughness, and tool chipping rate, some manufacturers use shock absorbers specifically designed for scraping hard tooth surfaces. Shock absorbers are installed on the knife holder. of the knife holder. It is said that this device can effectively reduce the chipping rate of carbide scrapers, improve the roughness of tooth surface, reduce the need for powerful and high-rigidity hobbing machines, save equipment investment, and can replace in a to some extent expensive grinding of teeth. this is particularly important for large diameter hard gears.

Conclusion

The process of scraping tooth hard surfaces has advantages and has become a widely used tooth hard surface scraping treatment method, which reduces the grinding pressure of gears to a certain extent. Due to the availability of stiffer machine tools and high-quality carbide tool materials and coatings, hardened hobbing has become an effective processing method. The factory’s actual application results show that the tooth hard surface scraping processing technology has wide applications.

My name is woodykissme, and I regularly share content about mechanical transmission and gear processing. Friends interested in this aspect can follow me. I hope to discuss with you:

Methods of designing and processing gears, and related matters relating to the design, manufacture and operation of cutting tools used to process gears.

Related technical issues such as gear milling cutter design calculation methods, related application development, automatic drawing of CAD secondary development, etc.

In terms of tool application, cutting parameters, coating and tool life, problems encountered in processing and solutions, etc.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.