The Advantages and Challenges of Composite Materials: A Comprehensive Guide

Composite materials are a new frontier in the world of materials science, offering a range of benefits and challenges that have far-reaching implications for industries such as aerospace, energy, and manufacturing.

What are Composite Materials?

Composite materials are made by combining two or more materials to create a new material with unique properties. These materials can be based on plastic, metal, or ceramic, and the choice of matrix and reinforcement can significantly affect the final product’s properties. For example, carbon fiber-reinforced polymers (CFRP) and glass fiber-reinforced polymers (GFRP) are popular composite materials used in various industries.

Characteristics of Composite Materials

Composite materials have several advantages over traditional materials, including:

- Reduced weight

- Increased strength and stiffness

- Improved impact resistance and fatigue resistance

- Better thermal and acoustic insulation

- No corrosion or degradation

However, composite materials also present some unique challenges, particularly when it comes to processing and manufacturing. The use of multiple materials requires careful consideration of the matrix and reinforcement, which can be complex and time-consuming.

Processing and Manufacturing of Composite Materials

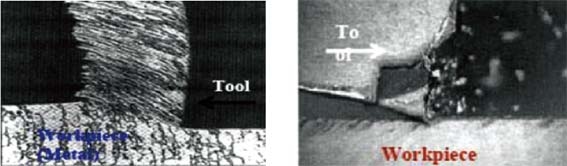

The processing and manufacturing of composite materials are intricate and multifaceted. The choice of processing method, tooling, and technique can significantly impact the final product’s properties. There are various tools and techniques available for processing composite materials, including cutting, drilling, and milling.

Cutting Composite Materials

Cutting composite materials requires specialized tools and techniques to ensure accurate and precise cutting. Diamond-coated and PCD (polycrystalline diamond) tools are commonly used, as they can withstand the high hardness of composite materials. The cutting direction and angle can significantly affect the quality of the cut, and the tool’s lifespan can be extended by proper maintenance and sharpening.

Drilling Composite Materials

Drilling composite materials can be challenging, as the matrix and reinforcement can cause the drill bit to wear down quickly. Diamond-coated and PCD drills are designed to mitigate this issue, and the choice of drill bit can significantly impact the quality of the hole and the tool’s lifespan.

Milling Composite Materials

Milling composite materials requires precise control and attention to detail. The use of PCD milling cutters and diamond-coated cutters can help to achieve high-quality surface finishes and improve the tool’s lifespan.

Real-World Applications of Composite Materials

Composite materials are used in a wide range of applications, including aerospace, energy, automotive, sports equipment, and medical devices. The use of composite materials can significantly reduce weight and improve performance, making them an attractive option for industries where weight reduction is critical.

Conclusion

Composite materials offer a range of benefits and challenges, from reduced weight to improved performance. The processing and manufacturing of composite materials require careful consideration of the matrix and reinforcement, as well as the choice of tooling and technique. By understanding the intricacies of composite materials and the challenges they present, manufacturers can create innovative products that meet the demands of modern industries.

Case Studies in Composite Materials

Case 1: Russia Rusaviaiter

- Material: Carbon fiber

- Tool: JC840 left-hand cutter with right-hand edge

- Contour filling: AE = 5 mm

- AP = part thickness 8 mm

- VC = 180 m/min

- Fz = 0.02

- Result: Smooth filling, smooth cut, good surface quality

Case 2: Airbus (France)

- Material: Carbon fiber

- Machine-Tool: Jomach 159

- Shangao tools: Standard PCD drill bit x31, diameter 6.35 mm

- Linear speed: VC = 180 m/min

- Feed: 850 mm/min

- Result: Small cutting burrs, tool lifespan >60 minutes

Case 3: A certain airplane customer

- Material: Carbon fiber + aluminum honeycomb + carbon carbon carbon

- Machine-Tool: CRENO Liner 5-axis

- Shangao tools: JC860 cutter for treatment of honeycomb, diameter 10 mm

- Cutting width: Milling groove

- Cutting depth: 40 mm

- Linear speed: 160 m/min

- Feed: 300 mm/min

- Result: Smooth cutting, good surface quality, tool lifespan >60 minutes

In this article, we have explored the benefits and challenges of composite materials, including their properties, processing and manufacturing, and real-world applications. By understanding the intricacies of composite materials, manufacturers can create innovative products that meet the demands of modern industries.