The machining of the mirror means that the treatment surface can be used to use images like a mirror. , extend the fatigue of the life of the play; The process of treatment of the polishing mirror is mainly used to reduce the room roughness of the room.

1. Mechanical polishing Mechanical polishing consists in eliminating the polished polishing method by cutting and the plastic surface of the surface of the material. such as rotation tables can be used. The superb search is a special grinding equipment. The use of this technology can achieve RA0.008 μm surface roughness, which is the highest among the different polishing methods. This method is often used in optical molds.

2. Chemical polishing The chemical polishing is to allow the material to be slightly concave part of the surface of the material in the chemical environment, which is correctly dissolved that the concave part, thus obtaining a smooth surface. The main advantage of this method is that no complex equipment is required. The central problem of chemical polishing is the preparation of the polishing fluid. The surface roughness obtained by chemical polishing is generally 10 μm.

3. The basic principle of electrolytic polishing and electrolytic polishing is the same as chemical polishing, that is to say that the surface of the selective dissolved material is slightly protruding, which makes the surface smooth. Compared to chemical polishing, the effect of the reaction of the cathode can be eliminated and the effect is better. The electrochemical polishing process is divided into two stages: (1), the macro level product is propagated to electrolyte, the geometric surface of the material decreases, RA> 1 μm. (2) The anodization of the microman dish, the brightness of the surface is increased and RA <1 μm.

4. Ultrasonic polishing puts the part in the abrasive suspension and the place in the ultrasonic field. The Macro-Force of Ultrasonic Treatment is small and does not deformation of the parts, but the production and the work installation are difficult. Ultrasonic treatment can be combined with chemical or electrochemical methods. Based on the corrosion and electrolysis of the solution, the ultrasonic vibration agitation solution is applied to the dissolving surface of the surface of the room, and corrosion or electrolyte near the surface is uniform; Also inhibits the corrosion process, which is conducive to surface lighting.

Equipment sales phone: 135 2207 9385

5. Fluid polishing Fluid polishing is the purpose of relying on a high -speed liquid and the surface of the grinding particles which is transported to reach polishing. Current methods are as follows: abrasive spray treatment, treatment of liquid jets, fluid power grinding, etc. Fluid power grinding is driven by hydraulic pressure, so the liquid environment carrying abrasives is high on the surface of the room at high speed. The environment is mainly used to use special compounds (polymer -type substances) which are influential under low pressure and are in abrasives.

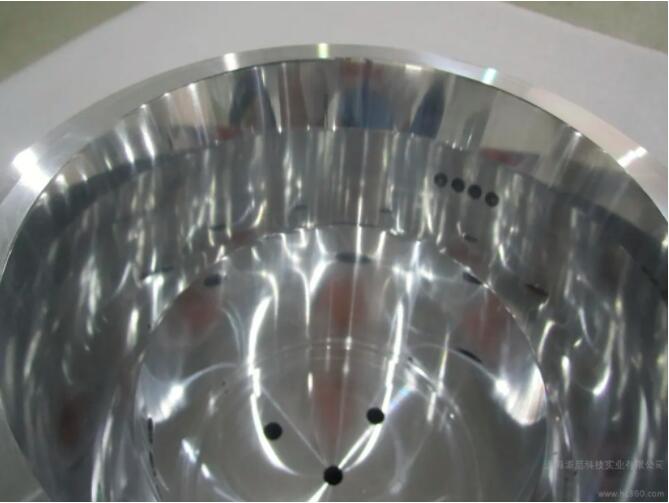

6. Polishing mirror Mirror surface, magnetic grinding and magnetic polishing polishing must form an abrasive brush by magnetic abrasives under the action of the magnetic fields and the grinding treatment of the room. This method has high treatment effectiveness, good quality, treatment conditions that are easy to control and good working conditions. With the appropriate abrasive, surface roughness can reach RA0.1 μm. Polishing in the treatment of plastic mold is very different from the surface polishing required by other industries. It has not only high requirements to polish, but also has high standards for surface flatness, gentleness and geometric precision. Surface polishing is generally necessary only to obtain a light surface. The standard for the treatment of mirrors is divided into four levels: AO = RA0.008 μm, A1 = RA0.016 μm, A3 = RA0.032 μm, A4 = RA0.063 μm. And polishing does not meet the requirements, therefore the treatment of the mirror of the precision molds is mainly mechanical polishing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.