The system has analyzed several methods of processing the surface of the hydraulic cylinder and their characteristics currently adopted by our company. accomplished.

Compared to piston compressors, screw compressors have many advantages such as few wear parts, a long maintenance cycle, high resistance to the impact of the liquid, a large and capable load adjustment range to operate under difficult environmental conditions. Compressors have become the main compressor model for refrigeration systems.

The screw compressor is a volume compressor that can reach an energy adjustment without a step. As an increase in load and a decrease in the surface quality of the mobile loading mechanism determines the softness of the adjustment piston.

The hydraulic cylinder block is the most important part for the increase and decrease in the energy of the compressor, and the surface roughness of the hydraulic cylinder bore directly affects the precision of the energy adjustment and the sensitivity of the answer. Our company has adopted a variety of processes to improve the quality of surface treatment over the years. The damping caused by surface roughness is also considered on the piston. cannot meet the requirements, and there are often inappropriate production provisions.

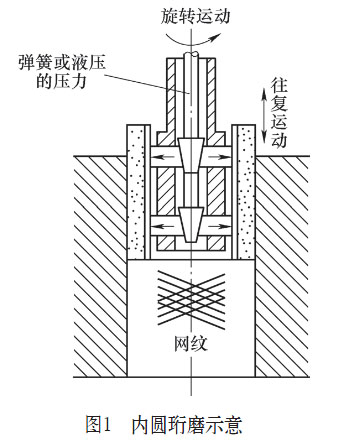

1. Principle of perfection work

The improvement consists in using one or more oil stones installed on the circumference of the perfection head to radially extend the oil stones by the extension mechanism (5, type of propulsion from our company) to press them towards the wall hole wall to produce a certain amount of face contact (see Figure 1). At the same time, the perfection head turns and reciprocal, and the parts remain impassive, thus reaching improvement. The improvement head and the machine of the machine or between the improvement head and the floating room. The formation of the surface of the hole has essentially the characteristics of the creation process. The so-called creation process is mutual research and cutting of oil and stone walls to form the hole walls and oil surfaces. Its principle is similar to the principle according to which two plan displacement plates are blurred against each other to form a plan.

During perfection, the perfection head turns and alternative or the head of perfection turns, and the reciprocal room of the room, the machining surface forms a helical cutting path that crosses, and the number of rotations of the head of Rabat is not an integer during each alternative racing time, therefore, therefore, therefore between the two features, the perfection head is shifted at an angle in the circumference compared to the room, so that the movement of movement of each Abrasive particle on the perfection head on the wall of the hole is not repeated. In addition, each time the height head turns, the cutting stone cutting trajectory and the previous rotation overlap in the axial direction, which makes the front and rear connection smoother and even. During the perfection process, the chances of interfere with each point of the wall of the hole and the surface of the oil stone are essentially equal. Consequently, as shaving progress, interference points are constantly generated on the surface of the hole and the surface of the oil stone, which grinds these interference points and will generate new interference points and More, which will continue to grind, causing the contact area of the hole contact area and the surface of the oil stone increases, and each other. .

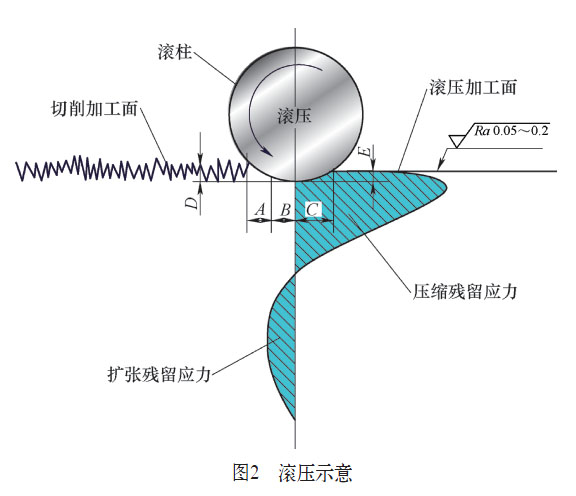

2. Rolling principle principle

The principle of treatment of rolling tools is like a roll pressing on an unequal road dish, which consists in using a very smooth roller to roll the transformed metal surface, extruding the high convex part of the surface to the part Low concave, which thus makes the treatment the surface to obtain the effect of being smooth as a mirror is a method of treatment of plastic, as shown in Figure 2, where A is the bearing area, B is the area Plastic deformation, it is the smoothing area, D is the amount of rolling and E is the amount of elastic recovery. The surface of the part to be treated not only reduces the value of the roar value of the surface from 1.6 to 3.2 μm to 0.1 to 0.2 μm, but also improves hardness, resistance to Wear, corrosion resistance and surface tightness to be treated and eliminated early wear.

3. Principle of high -speed machining CBN

In mechanical treatment, cutting temperature is an important restrictive parameter. And the cutting temperature are not. The cutting temperature of the conventional cut in the initial area makes the part and the tool unbearable, and is called “Dead Valley”. However, after the breakthrough, enters the ultra-high speed cutting zone, the cutting mechanism for material changes, and the cutting process becomes easier and easier than conventional speeds, but efficiency increases by 10 times. During the ultra-high speed cut, the change of friction coefficient between the tool and the chips has a large impact on the cutting force, the cutting heat, the accumulation of fleas, the wear of the tool and the quality of surface treatment. In high speed, the average friction coefficient between shavings and the tool decreases, resulting in a cutting of cutting force and a decrease in heat by friction.

Selfless material tools are the prerequisite for carrying out an ultra-high speed treatment. Cubic boron nitride and cubic boron nitride (CBN).

The CBN knives have the following characteristics: ① high hardness and good wear resistance. ② Good thermal stability. Good chemical stability. Good thermal conductivity and small friction factor. ⑤ Bad strength and tenacity. Therefore, CBN tools are particularly suitable for high -speed finish, especially in dry cut.

4. Shaving treatment test

Perfection oil stone uses diamond abrasives and oil stone is less worn during treatment, that is to say that the amount of part of the oil stone is very small. Consequently, the accuracy of the hole depends to a certain extent on the original precision of the oil stone on the perfection head. Therefore, when using the diamond nitride oil and cubic boronstone, the oil stone must be well cut before perfecting to ensure the precision of the holes.

Gray Fast Fon (HT300) The speed of the treatment line is increased to more than 50 m / min, and the alternative perfection speed is 15 to 20 m / min. The pressure of the oil stone at the hole wall is set to 0.3 to 0.5 MPa (about 1 MPa when it is almost perfected, and <0.1 MPa when it is finely perfected) . Since the oil and stone are in contact with the part during the improvement, the vertical pressure of each abrasive particle on the surface of the room is only 1/100 ~ 1/50 of time during grinding. , the temperature of the cutting area is maintained at 50 ~ 150 ℃ in the beach, it is conducive to reducing residual stress on the treated surface and improving the quality of the surface. In order to rinse the chips and reduce the temperature of the cutting area and the surface roughness value, the cutting fluid is in kerosene.

5. Ringing treatment test

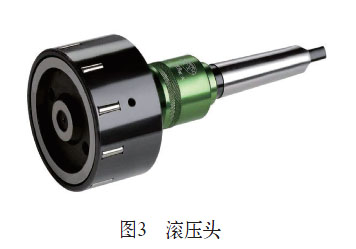

The bearing head is illustrated in Figure 3, and the hardness of the rolling material is less than 40 HRC. The surface roar value of the preterity hole before the turnover is Ra <3.2 μm. The remaining allowance of the opening of the part before the bearing is 0.02 ~ 0.07 mm (specifically determined on the basis of the room material, the opening and the heat treatment status of the part) . The rolling speed is 25 to 40 m / min and the quantity of power is 1.0 to 1.5 mm / r. When you work, use an oily cutting liquid with low viscosity clean or low -viscosity lubrication oil, and the bearing head should be cleaned frequently.

(1) The processing technology of the first test is:

1) The bore of the hydraulic cylinder is thick and semi-finished to φ 151.7 mm (due to the limitation of the diameter, φ 140 mm is treated in the rolling diameter of the bear head).

2) Finish the hole φ (1 5 2 +0. 0 0) mm (the surface roughness value is approximately RA = 1.6 μm).

3) Adjust the amount of bearing to φ (152 + 0.04) mm (the diameter of the bearing head and the bore of the cylinder is 0.03 mm). The rolling parameters select the pin speed n = 80m / min and the power speed VF = 88 mm / min. L = 218 mm, the running time of the bearing is 2.47min / piece. The size of the cylinder bore φ (152 + 0.015) mm after the bearing is not deformed.

(2) The treatment technology for the second sample is:

1) The bore of the hydraulic cylinder is thick and semi-finished to φ 151.7 mm (due to the limitation of the diameter, φ 140 mm is treated in the rolling diameter of the bear head).

2) Finish the hole at φ (1 5 2 +0. 0 1) mm, and the surface roughness value is approximately RA = 6.3 μm.

3) Adjust the amount of bearing to φ (152 + 0.08) mm (the diameter of the bearing head and the bore of the cylinder is 0.07 mm). The rolling parameters select the pin speed n = 80m / min and the power speed VF = 88 mm / min. L = 218 mm, the running time of the bearing is 2.47min / piece. After the bearing, the size of the cylinder bore φ (152 + 0.04) mm is 0.01 mm.

6. CBN treatment test

Cubic boron nitride (CBN) is a hard -hated material of hardness only in front of the diamond. Its principle is that it has a low affinity with iron metals, it is therefore mainly used for cutting and treatment of iron metals. It has not only many properties of excellent diamond properties, but also has higher thermal stability and chemical inertia with iron -based metals and their alloys. Count on grinding.

The CBN tools are a type of superhard material product which is agglomerated from many fine grains (0.1 ~ 100 μm). In addition to having high resistance to hardness and wear, it also has high tenacity, chemical inertia and red hardness. Difficult to process materials such as hardened steel and cold hard cast iron. The tool has a clear cut, good conformity, high wear resistance, unit wear, little correction time, and is conducive to automatic processing, and is particularly suitable for finish. Process tests can be carried out on similar machine tools.

Using the Sandvik Colomman Cubic boron nitride tool (see Figure 4), HT300 material (see Figure 5). The process is as follows:

1) The finish allowance is 0.30 mm, which improves the accuracy of the rough treatment dimensionality and reduces thermal deformation to ensure a uniform cut allowance and prolong the lifespan of the tool.

2) Dry cut. At higher cutting speeds, a large amount of cutting heat is removed by chips and rarely remains on the surface of the room, affecting the quality and precision of the treatment surface.

3) The fine bore insert uses a high resistance diamond blade and high toz with a rounded corner radius of 0.4 mm.

4) Select the cutting parameter for cutting speed VC = 120 m / min, the quantity of power f = 0.1 mm / r and the volume of the back-food tool AP = 0.2 ~ 0 , 3 mm.

7. Results of improvement tests

Quantity of improvement: 10 pieces of hydraulic cylinders LG20 and LG16; Show to improve.

Thanks to the test, we can conclude that shaving the hydraulic cylinders blocks below LG20 is possible in terms of process, and the quality of perfection surface has been considerably improved. back.

8. Results of rolling tests

Sample 1: Since the lower hole is treated with a new blade, the surface roughness value of the hydraulic cylinder bore can reach RA = 1.6 μm once the bearing is finished, so that the difference in the ‘Effect after rolling is not very obvious.

Specimen 2: Since the effect of the first test piece is not very obvious, the blade is replaced by an old blade when the second test part is processed. The first part. MM. The reason for the analysis may be that the wall of the pores is too thin. According to data, when processing with rolling tools, the part must have sufficient wall thickness (the outside diameter is greater than 15% of the opening). reduced after treatment.

Once the casting is rolled, you can always see in the naked eye that there are tiny black particles on the surface of the flow. As plasticity decreases and hardness increases, the quantity of permanent deformation decreases accordingly. In general, melting has a bad rolling effect. When the cast iron is rolled, when the hardness of the flow material is unequal, defects (air holes, sand holes, etc.) on the rolled surface will be immediately exposed. Therefore, when there are many faults on the surface of the flow and the quality is poor, the rolling process should not be used.

9. Results of CBN processing tests

After tests and verification, CBN high speed machining can also achieve high surface quality, meet the design requirements and reach “boring instead of perfecting”.

10. Comparative analysis of three process methods

(1) Advancement is beneficial for improving the failure of screw compressors in the second position of the line “increase in load and failure”, which can considerably reduce the frequency of the increase in load and the decrease in head failures. The regulations are as follows.

1) Improvement range: A perfection process is added to LG12, LG16 and LG20 hydraulic cylinder blocks, which are arranged to be made after the end.

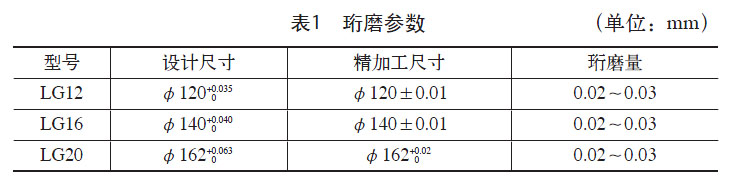

2) Perfection parameters: perfection parameters are presented in Table 1.

3) Staff arrangement: Since the work intensity of this process is not high and that the pace is not assessed, the operator’s provision is allocated internally according to the real production situation And works part -time.

(2) The specific requirements for the rolling and rolling process are as follows.

1) Method to adjust the diameter of the rolling tool. ① Use a micrometer to measure the diameter of the tool. ② Push the ladder adjustment sleeve in the direction of the handle and turn left and right at the same time, so that the diameter of the tool can be adjusted, the left rotation decreases and the right rotation increases and that The value of each scale is 0.002 5 mm 5 mm. ③ After setting the diameter, release the aluminum shell and automatically lock the diameter. ④ When processing blind holes and steps, the bottom is approximately 0.5 to 1.0 mm and cannot be treated. The needle can gently touch the bottom of the hole. If there are parts with conical shapes and R at the bottom, a padded limit block must be added to prevent the tool from stuck.

2) Wall thickness requirements for processing parts. The use of rolling tools to treat the part must have sufficient wall thickness (the outside diameter is more than 15% of the opening). The problem occurs, the following solution can be used: ① Reduce the bearing volume. ② Use lighting to support the external circumference. ③ Treatment before treating thin walls. The maximum maximum limit of the hardness of the part which can be processed by rolling tools is 40hrc. If you meet a high hardness material treatment, the lifespan of the tool will be shortened due to high pressure on the tool.

3) Treatment of surface size and roughness requirements. The size before treatment, surface roughness, material and requirements after treatment are all very linked and must be considered globally. For example, the depth of concave and convex parts before treatment, the amount of treatment can be used to increase depression parts by treatment to obtain a smooth surface. that various products work first. 2. The bearings allocation is as small as possible. Rounding is a high -demand finishing process. Generally, the bearing margin for ordinary steel parts is 0.02 to 0.04 mm, the rolling margin for copper and aluminum parts is 0.03 ~ 0.07 mm and the roughness value of surface RA <3.2 μm.

(3) CBN treatment CBN tools use ordinary CNC improvement tools, but the price of the insert is high (saving 300 yuan / part, high precision 1 100 yuan / part), the amount of treatment is 10 parts / Piece, and it is therefore, high -speed treatment equipment has certain limits.

11. Conclusion

Thanks to the experimental verification of different surface processing technology methods, a series of process parameters is obtained and a complete technical and economic analysis is carried out. It is concluded:

1) Conventional products with nominal diameter of less than 200 mm (hole diameter ≤ 165 mm), output by lots> 10 parts / lot, personnel attached to refine part -time, costs increase by ≤ 10 yuan / lot.

2) New products may not form products per lots (< 3 parts / batch) and products with diameters ≥165 mm (product output with large specification ≤ 5 parts / lot), use CBN tools directly to treat The increase in the costs of ≤ 30 yuan / the lot, although the unit cost of batch products has increased significantly, but it avoided investments in bulk equipment (the minimum quote for improvement machines is 560 000 yuan per unit).

3) The rolling process is characterized by the fact that the melting has no extension, high cleanliness requirements before rolling, high price and easy -to -head damage. A saving backup process.

Thanks to the verification of the three process methods, the following optimal cutting parameters are obtained:

1) When the roughness value of the boring surface RA = 1.6 μm, the improvement margin is 0.02 to 0.04 mm.

2) The rolling tools are replaced by interior production and the balance does not exceed 0.025 mm on one side.

3) CBN blades are suitable for high speed volume, snack volume and fast power characteristics. The above conclusions provide a basis for the reasonable provision of surface precision treatment in the production organization of small lots of our company for several varieties, and also provide a reference to each process staff to design process processes appropriate.

According to the conclusion of verification, after having used the different methods of above, the quality of processing of the surface of the hydraulic cylinder blocks has been considerably improved, the increase in load and the decrease in sweetness have been considerably Improved, while the cost only increased slightly. According to quality feedback information, the increase in load and the decrease in the failure rate of screw compressors increased from 8.3% original to less than 1%, which is of great importance for energy saving and reduction in compressors’ consumption.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.