In the rapidly evolving landscape of the manufacturing industry, efficiency and precision have become paramount. Among the various tools that drive productivity in manufacturing, the semi-automatic wire cutting machine stands out as a powerful assistant. This innovative technology has revolutionized how manufacturers approach wire processing, offering remarkable speed, accuracy, and adaptability across numerous applications.

## Understanding the Semi-Automatic Wire Cutting Machine

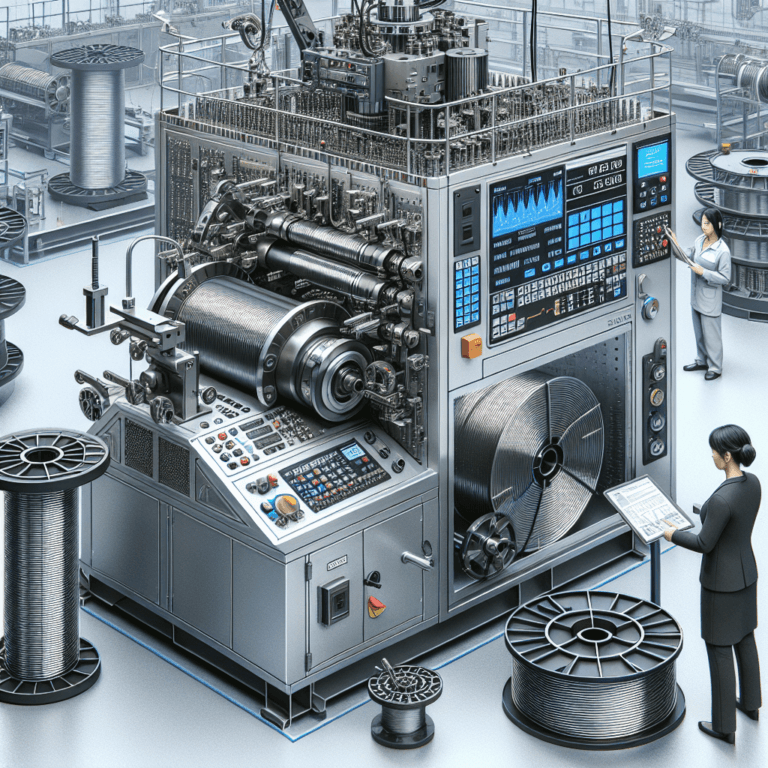

A semi-automatic wire cutting machine is designed to automate the cutting process of various types of wire, including copper, aluminum, and steel wire. Unlike fully automatic machines, semi-automatic models require some manual input but significantly reduce the effort needed for cutting tasks. This hybrid approach allows operators to maintain a level of control while enjoying the benefits of automation.

These machines typically consist of several key components: a cutting mechanism, a control panel, a feeding system, and a safety enclosure. The cutting mechanism can employ different technologies, such as pneumatic or rotary cutting, depending on the machine design and wire type. The feeding system ensures consistent wire length by precisely delivering wire to the cutting area.

## Key Features of Semi-Automatic Wire Cutting Machines

### Precision Cutting

One of the standout features of semi-automatic wire cutting machines is their ability to produce precise cuts. The advanced technology within these machines minimizes human error and ensures consistent dimensions, resulting in clean and accurate wire segments. This precision is critical in applications that require specific wire lengths or conditions.

### Ease of Use

Although these machines automate much of the wire cutting process, they remain user-friendly. Operators can quickly set the desired wire length and cutting speed through the intuitive control panel. Many semi-automatic machines also offer programmable functions, allowing users to save and recall specific settings for recurring tasks, thereby further enhancing efficiency.

### Flexibility and Versatility

Rather than being limited to a single wire type, these machines can handle various materials and sizes. This versatility makes them ideal for businesses that work on multiple projects or manufacture different products. Operators can easily switch between different wire types, reducing downtime and increasing overall productivity.

### Safety Features

Safety is a crucial consideration in any manufacturing environment. Semi-automatic wire cutting machines are designed with multiple safety features to protect operators during the cutting process. These may include emergency stop buttons, safety guards, and sensors that prevent the machine from operating when safety requirements are not met.

### Enhanced Production Speed

Production speed is a defining factor in manufacturing efficiency. Semi-automatic wire cutting machines can operate significantly faster than manual cutting methods, allowing organizations to meet increasing demands without sacrificing quality. The reduction in manual labor also enables operators to focus on other critical tasks, further optimizing workflow.

## Benefits of Investing in Semi-Automatic Wire Cutting Machines

### Increased Productivity

By streamlining the cutting process, businesses can increase their output and meet deadlines more effectively. With the capability to cut wire at a rapid pace, semi-automatic machines allow manufacturers to keep up with production schedules, leading to improved customer satisfaction and potentially increased sales.

### Cost-Effectiveness

Although there is an initial investment in purchasing a semi-automatic wire cutting machine, the long-term savings are significant. The reduction in labor costs, coupled with the increased speed and precision, results in a quick return on investment. By minimizing waste through accurate cuts and improved production methods, companies can further enhance their profitability.

### Quality Assurance

The consistency provided by semi-automatic machines supports strict quality control measures. The precision in cutting reduces the number of defective products, helping to maintain quality standards that meet or exceed customer expectations. This reliability can lead to repeat business and a solid reputation in the industry.

### Improved Worker Satisfaction

Automating the more tedious aspects of wire cutting allows workers to engage in more skilled tasks. This shift can enhance job satisfaction, reduce turnover, and create a more motivated workforce. Moreover, with reduced physical strain and the risk of injuries associated with manual cutting methods, employees can work in a safer environment.

## The Applications of Semi-Automatic Wire Cutting Machines

### Electrical Manufacturing

In electrical manufacturing, the need for precise wire lengths is paramount. Semi-automatic wire cutting machines are extensively used to produce wire harnesses, cables, and other electrical components. Their ability to handle different wire types and sizes makes them ideal for a sector that demands high reliability and conformity.

### Automotive Industry

The automotive sector is another significant benefactor of this technology. Manufacturers utilize semi-automatic wire cutting machines to create wiring for vehicles, ensuring safety and performance standards are met. The speed and precision offered by these machines support the production of complex electrical systems and contribute to streamlined assembly processes.

### Construction and Building

In construction, various electrical and structural applications necessitate accurate wire cutting. Semi-automatic machines cater to the dynamic needs of construction by supplying precisely cut wires for power distribution, communication systems, and more, making them invaluable for electrical contractors.

### Aerospace and Defense

The aerospace and defense industries place a strong emphasis on the reliability and quality of every component. Semi-automatic wire cutting machines are employed to produce wiring for aircraft and defense systems, where exact wire lengths and faultless quality are non-negotiable requirements.

### Custom Fabrication

For businesses offering custom fabrication services, semi-automatic wire cutting machines provide the flexibility needed to accommodate unique client requests. Whether for one-off projects or small-batch production runs, these machines enable manufacturers to quickly adapt to varying specifications without significant downtime.

## Choosing the Right Semi-Automatic Wire Cutting Machine

When considering a semi-automatic wire cutting machine, various factors come into play:

### Machine Specifications

Evaluate the machine’s specifications, including cutting capacity, wire feed options, and precision levels. Ensure that the machine aligns with your specific requirements based on wire materials and sizes commonly used in your processes.

### Brand Reputation

Consider the manufacturer’s reputation and their commitment to quality and after-sales support. Research user reviews and feedback to gain insights into the reliability and performance of the machines.

### Cost and Budget

While it’s essential to weigh the upfront costs, consider the long-term savings generated from enhanced automation and reduced labor. Assess your budget and establish a balance between initial investment and expected operational benefits.

### Maintenance and Support

Look for machines that come with clear maintenance instructions and reliable customer service. A machine that is easy to maintain can save time and resources in the long run.

## Conclusion

The semi-automatic wire cutting machine is undoubtedly a powerful assistant in the manufacturing industry. By enhancing precision, speed, and flexibility, manufacturers can significantly optimize their operations, reduce costs, and improve output quality. As industries continue to evolve, investing in this technology presents an opportunity to stay ahead of the competition and meet the standards of modern consumer demands effectively.

In an age where efficiency and quality are paramount, semi-automatic wire cutting machines are not just tools; they are pivotal drivers of productivity and excellence across multiple manufacturing sectors. For any organization keen on staying competitive in today’s market, adopting such technology is not merely an option; it is a necessity.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.