2023Year7moon17Japan, according to Mohou.comlearnSwiss pioneer of inkjet printingScronaThe company develops microelectromechanical systems (MEMS) based onMEMS)of3DPrinting technology for productionMicroLEDmonitor. Unlike traditional inkjet technology,ScronaElectrostatic inkjet printing uses electrical force to extract droplets from a nozzle, increasing efficiency and enabling the use of a wider range of materials, including high viscosity inks. Their new technology offers as little as0.5 µmprinting resolution, ideal for electronic applications with small components.

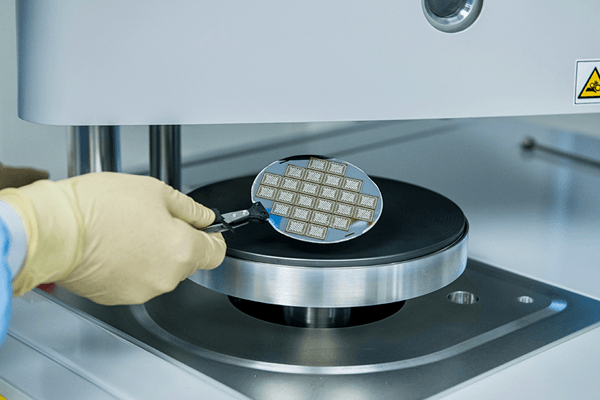

△ Printed plate with MicroLED matrix. (Image source: Scrona)

ScronaThe core of printhead technology is their exclusive propertyMEMSchip, after more than ten years of development. The chip can form thousands of nozzles on a small area, enabling high-volume manufacturing capabilities. The accuracy of this technology is excellent, with placement accuracy better than1mmand can be extended to have up to128A wider range of nozzles.

ScronaThe objective is to bring functional printing to additive manufacturing, a field with high added value. usingMEMSUsing silicon and digital control capabilities, they overcome the challenges of individual nozzle control and reduce the high voltage required for operation. This allows the use of thousands of nozzles and brings economic benefits.

ScronaPrint nozzle scalability is a key factor in meeting production requirements. The current prototype has10nozzle, butScronaThe planned development has1000nozzle print head for a faster and more efficient printing process. The company is also working to improve the resolution and precision of its print nozzles to meet the needs of advanced packaging, back-end processes and printing materials such as protection and encapsulation .

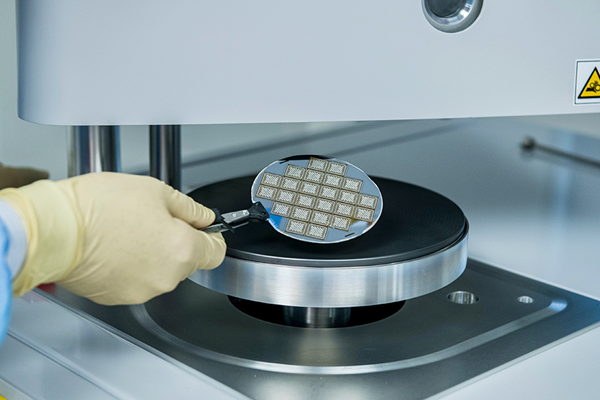

△MEMS 3D printer (Photo source: Scrona)

ScronaAn important advantage of this technology is that there is no thermal load during the patterning process, which allows the use of materials such as perovskites. The company also developed an active solvent removal system to prevent condensation on the print head to meet the challenges of high-speed, high-volume production.

Reference sources:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.