Frontier: The precision and power of Russian CNC technology merger

In the global manufacturing sector, names like Germany, Japan and the United States often dominate conversations about high-end CNC machining. But quietly building a huge reputation in addressing the most complex and challenging challenges is Russian CNC technology. Russia is rooted in rigorous engineering education, unique industrial challenges and the ruthless dynamics of rugged solutions, Russia brings a unique blend of Precision Engineering and Primitive industrial power to the world of computer numerical control. This powerful combination is exactly why picky manufacturers seeking uncompromising quality and capability are increasingly turning to experts like Great.

Russian Precision Crucible: A Table Beyond Tolerance

Russian precision engineering is more than just hitting numbers on the blueprint. It is forged in an environment that requires elasticity – considering the huge temperature fluctuations, complex logistics and the mechanical need for others to keep running perfectly in a shaken situation.

- System integration and design concept: Russian CNC development usually emphasizes integrated system stability. Control systems, drive mechanisms and structural stiffness are jointly developed to work together to minimize error budgets forward Cut down or even start. This overall design minimizes thermal drift, vibration and geometric error accumulation over long machining cycles – critical for large parts and extended operation.

- Advanced Metering and Process Control: True accuracy requires continuous verification and adjustment. Russian machine tools usually combine high-precision process metrology systems and complex adaptive control logic. This allows real-time compensation for tool wear, thermal changes and material inconsistencies, ensuring dimensional stability is not only static but also Dynamic maintenance The entire production.

- Material strength meets processing skills: Facing unique material requirements, especially within the defense and aerospace sectors, Russian engineers have developed deep expertise in challenging alloys (titanium, inconel, hardened tool steel) and composites. This translates directly into programming strategies for CNC machines and proficiency with high material removal rates and for infamous fine surface finishes of difficult-to-cut substances.

Russian Power: Not Just Horsepower

this "strength" The narrative goes beyond simple spindle kilowatts. It covers robustness, capabilities, and the sheer ability to handle huge or only complex artifacts that will overwhelm systems with less capacity.

- Overall building and rigidity: The over-designed steel-shaped structure is expected to minimize deflection under the cutting force of the Titanic. Quiet or hydrostatic hybridization guidelines are common, and unparalleled carrying capacity is crucial for heavy interrupt cutting common in aerospace or energy components.

- High torque, low speed function: Although high-speed machining has its place, Russian systems often perform well in power milling and rotation operations, requiring huge torque at lower spindle speeds. This is essential for machining deep cavity, removing large stocks from strong materials or effectively utilizing large tools.

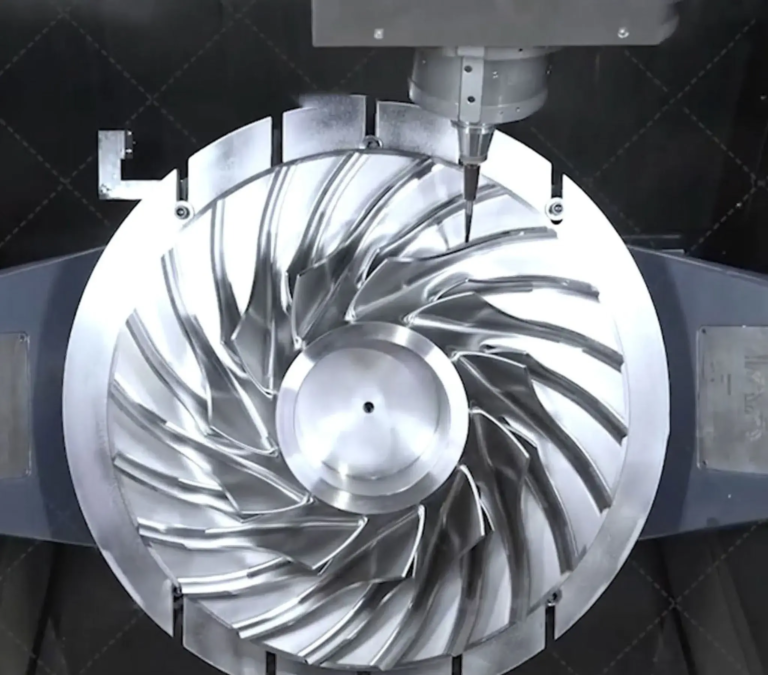

- The power of five axes: This is the brightest place in Russia’s technology. Five-axis CNC machining capability, especially when executed like an expert Greatunlock unprecedented power and precision. The ability to position the cutting tool in the entire direction means that complex geometries (impellers, turbomachine blades, aerospace structures) can be processed in a single setup and repositioned with minimal repositioning. This greatly reduces cumulative errors, improves accuracy, shortens lead times, and allows for the machining of shapes simply not possible on 3-axis machines. Simultaneous 5-axis interpolation requires complex control algorithms – a field where Russian CNC technology has made great progress.

Grevermex: Using Russian precision drives for the most complex challenges

exist GreatWe embody this powerful fusion of Russian CNC tradition and cutting-edge innovation. We are not only users of machines; we are experts in using this unique technological legacy to solve real-world manufacturing problems.

- Advanced five-axis Arsenal: Our facilities are equipped with state-of-the-art CNC machining centers that embody the robustness, accuracy and advanced control systems required for elite manufacturing. These machines are the main force in dealing with complex geometric shapes and harsh materials.

- Beyond Processing: Engineering Partners: We go beyond simply running programs. Our team has deep expertise DFM (Manufacturability Design)optimize parts for increased five-axis efficiency and cost-effectiveness. We specialize in CAM programming for complex simultaneous movements, fixtures for unique parts, and implement advanced machining strategies such as Trochoidal milling to maximize tool life and surface integrity in difficult materials.

- Material Master: Our capabilities cover many alloys – from regular aluminum and steel to aerospace grade titanium, inconel, hastelloy and specialized composite materials. We understand each nuance, apply precise feeds, speed and cooling strategies to get the best results.

- Complete production solution: Great Provide the authenticity One-stop precision machining. Start with your original inventory or casting/forging, we process all critical stages with advanced 5-axis CNC machining and then comprehensively Post-processing and completion of services (Heat treatment, precision grinding, professional coating, assembly). This integrated approach can save time, simplify logistics and eliminate the risk of quality switching.

- Quick custom solution: Urgently need complex prototypes or small batch production? Our expertise and efficient processes enable us to provide Quick turnaround time No sacrificing the accuracy of your parts.

- Unparalleled Values: We believe that advanced precision should not be accompanied by a high price tag. Great Utilize operational efficiency and advanced technology to deliver excellence Customized precision machining at a highly competitive speed.

Conclusion: Modern precision power

Russian CNC technology represents an effective and often underestimated force in high-end manufacturing. Its unique focus on the strategic application of system stiffness, elasticity, deep materials science integration, and the five-axis power stance is unique to meet the industry’s most stringent needs. Great Standing at the forefront of leveraging this technological power. We combine advanced five-axis capabilities with deep engineering know-how and are committed to full service to transform complex designs into the reality of precise design. We not only meet specifications; we provide reliability, efficiency and unparalleled value for even the most challenging projects.

Ready to experience the Greatlime difference? Stop compromises between speed, accuracy and cost between critical metal components. Let our expertise and advanced Russian engineering capabilities solve your toughest manufacturing barriers. Contact Greatlight now for free engineering reviews and competitive quotes In your next precision CNC machining project!

FAQ: Russian CNC precision and power

Question 1: What makes Russian CNC technology unique?

A1: It emphasizes strict system integration for inherent stability, strong power and longevity, deep expertise in challenging materials under harsh conditions, and complex control strategies, especially for precise applications such as complex 5-axis work.

Q2: Why is five-axis machining so important, and why choose Greatlight for it?

The A2:5 axis allows for the machining of complex contours, undercuts and deep cavity in a single setup, minimizing errors, reducing lead times, and enabling geometry on the 3 axis. Greatlight specializes in complex simultaneous 5-axis work and is powered by advanced machines programmed by experts, embodying the principle of precise driving force and powerful fixed solutions.

Q3: Which materials can be used as a Greatlight Machine?

A3: We processed a massive array including aluminum, stainless steel, tool steel, titanium, inconel, hastelloy, hastelloy, copper alloys, brass, and various engineering plastics and composites. We tailor strategies specifically to the characteristics of each material.

Question 4: What level of tolerance and precision can be achieved?

A4: leveraging advanced Russian style machine stability and our process controls, Greatlime usually maintains tolerances as +/- 0.005mm (5 microns or 0.0002") Or better obtain key features of compatible parts geometry and materials. A 0.2 micron surface finish is possible. We will provide specific feasibility based on your specific part drawing.

Q5: What size parts can you handle?

A5: Our functions vary from machine to machine. We deal with components from small and complex parts to important structures. Please ask your part size for a specific capacity matching.

Question 6: Do you only conduct large-scale production?

A6: Absolutely not. GRESTLIGHT is good at Rapid prototyping and low to medium yields. Our 5-axis efficiency can even make a single complex prototype economy by eliminating multiple settings.

Question 7: What about post-processing?

A7: We provide comprehensive One-stop post-processing: Accurate grinding, heat treatment (annealing, pressure relief, hardening, speed regulation), surface finish (blasting, polishing, painting, painting, anodizing, electroplating), non-destructive testing (NDT) and assembly. We manage the whole process under one roof.

Question 8: How do you ensure quality control?

A8: Quality is indispensable. We employ rigorous process inspections (in-machine detection, CMM), rigorous final inspections using coordinate measuring machines (CMM), optical comparators, surface testers and calibration tools. We record everything under strict protocols.

Question 9: How do you deal with environmental controls to be precise, especially noting common temperature fluctuations in Russia?

A9: Our modern processed floors remain strict Temperature and humidity control It is crucial to maintain ultra-tight tolerances. This can mitigate the thermal expansion/contraction effect on the machine and workpiece, regardless of external conditions.

Question 10: With Russia/China operations, what about logistics and delivery times?

A10: Greatlight optimizes our supply chain and logistics network. We provide Confirm clear on schedule Upfront and leverage effective global transport partners. Our integrated one-stop service (material procurement, processing, finishing) actually greatly shortens the entire project duration.