Benefit fromMulticolor FDM 3D printing is becoming increasingly popular thanks to innovative systems such as Bambu Lab’s AMS, which is paving the way for a new generation of machines capable of handling multiple filaments simultaneously. The system quickly inspired other manufacturers like Anycubic and Creality, making it possible to create multi-colored objects with greater precision and ease. However, the filament replacement process still remains very time-consuming and generates significant waste of material, particularly during the purification process necessary to avoid unnecessary mixing of colors.

It is in this context thatHeinz Löpmeier has developed an innovative solution: a rotating nozzle is able to change color without erasing the filament, thereby reducing waste and speeding up the printing process.

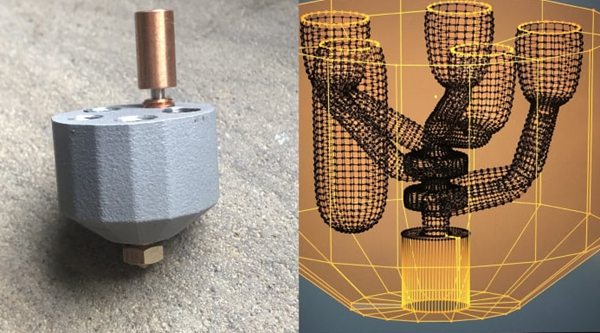

Heinz Löpmeier shared the process of creating his coaxial nozzle on his Twitter account.

Innovative concept: rotating nozzle

existHeinz Löpmeier, known as “sophier” on Reddit, shared his invention: the “rotating mixing nozzle”. Unlike previously mentioned systems, this nozzle does not require color purging between changes, eliminating filament waste. The nozzle works using a Python script in Blender, also created by Heinz Löpmeier and released as open source on github, which maps specific colors to the angles of the nozzle, allowing for smooth color transitions and even color effects. “halftone” (for gradient effects). ).

The concept emerged after years of experimentation with standard mixing nozzles, which tended to produce filaments of different colors by mixing them incompletely.“Toothpaste” effect. Heinz Löpmeier first attempted to control this effect using a printer with a platen that could rotate to change color, but this method proved too slow given the quality of the platen and the 3D printing to launch.

Operation and application

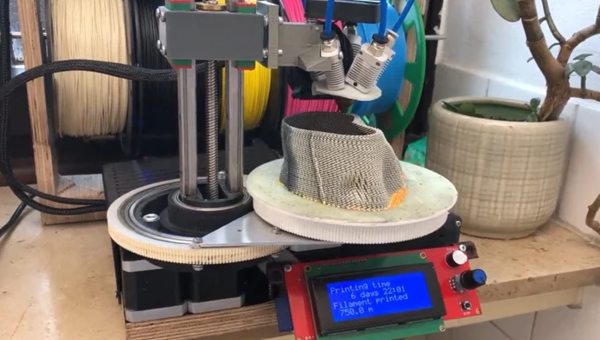

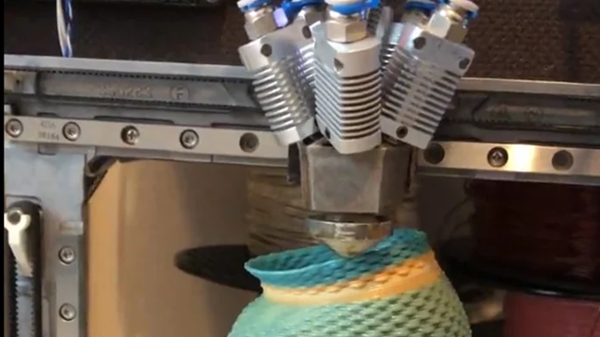

The operation of this rotating nozzle is relatively simple, but very effective. When in action, the nozzle rotates to change the color of the extruded filament without changing the mixing ratio of the three filaments used.Scripting in Blender also allows you to create subtle effects by positioning the nozzle at a specific angle between two colors, resulting in prints with complex tones and gradients without the need for additional structures (like color towers). exhaust).

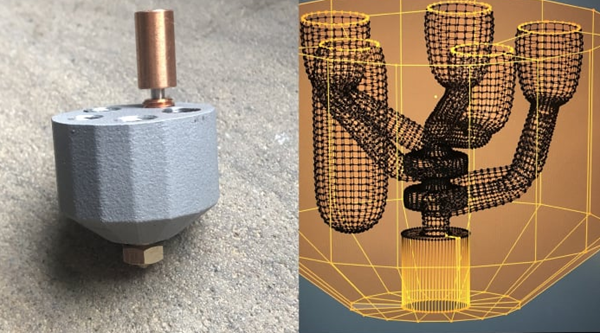

Heinz Löpmeier uses Marlin firmware, configured with an additional axis for nozzle rotation. One of the key design innovations is the ability of the Bowden tube to twist and unravel during print head movement, ensuring smooth operation and preventing kinking or clogging.

Previous prototypes used the same process but with rotating plates.

Powerful tools for creators

One of the main advantages of this system is that it is compatible withIntegration of Blender, a widely used 3D modeling software. Heinz Löpmeier developed an add-on called “nozzleboss” using Blender’s Python API, which allows you to directly manipulate G-code paths in Blender. This opens up huge creative possibilities, allowing users to sculpt or draw modifications directly within the toolpath.

Additionally, this approach eliminates the need for traditional slicing software, giving creators greater flexibility to customize their prints.

Outlook and impact

Heinz Löpmeier’s rotating nozzle could well mark a turning point in the field of FDM 3D printing, especially for those looking to minimize waste while enjoying the benefits of multi-materials. Its innovative design, although potentially worthy of a patent, is not yet protected, which opens the door for ambitious companies or individuals to turn it into a commercial product.

In addition to rotating nozzles,Heinz Löpmeier also uses non-planar 3D printing in his designs.

However,Heinz Löpmeier himself does not seem concerned about this prospect, preferring to focus on innovation rather than intellectual property protection. This attitude contrasts with recent patent disputes in the industry, notably between Stratasys and Bambu Lab.

With this rotating nozzle,Heinz Löpmeier not only offers technical solutions, but also a vision for more sustainable and efficient multi-material 3D printing. It remains to be seen how this technology will evolve and whether it will be adopted by the broader community of makers and 3D printing professionals. For more information on the project, check out Heinz Löpmeier’s article on Reddit.

source:3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.