Robotic hemming is an automated hemming technology widely used in automobile manufacturing and other fields for the manufacture of body parts such as door covers, fenders, roof covers and wheel covers of side panels. This technology installs a roller at the end of the robot arm and performs rolling and hemming along the panel fold line, which can replace the traditional press hemming process. Robotic hemming has the advantage of being flexible and suitable for large-angle hemming needs, but its production efficiency is generally lower than that of traditional press hemming. With the development of technology, the production efficiency of robot hemming is gradually improving and can now achieve higher production capacity.

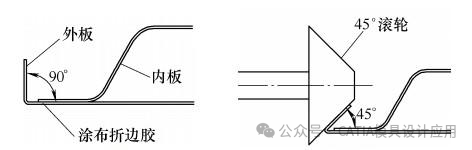

The robotic hemming process generally includes three steps: positioning clamping, pre-rolling and final hemming. During the hemming process, the robot trajectory is set to intersect in the forward and reverse directions to avoid the occurrence of stacking faults and avoid the accumulation of dimensional errors. Hemming pressure and speed are key process parameters that affect hemming quality and need to be adjusted based on specific conditions such as part material, geometric structure and hem type.

The application of robot hemming technology can improve production efficiency, reduce labor costs, improve product quality, and provide a high degree of flexibility, which can adapt to the needs of hem of different designs and body parts. With the continuous improvement of technology, robot hemming has broad application prospects in the field of intelligent manufacturing.

Advantages of robotic hemming:

Low one-time investment in equipment and low maintenance costs: Robotic hemming systems generally include hem fixing systems, roller systems, robots and their control systems. Compared with traditional press hemming, the costs of robotic hemming equipment are lower, and the maintenance costs are also lower. .

High degree of flexibility: Robotic hemming technology is suitable for various production pace requirements and can adapt to diversified production needs.

Small footprint: The tire mold design of the robotic hem is more compact and takes up relatively less space.

Improve appearance quality: The robot piping can achieve a smooth outer surface without defects such as indentations and bumps, which improves the appearance quality of parts.

Increase overall strength and stiffness: During the hemming process, the robot hem can better control the strength and uniformity of the hem, thereby increasing the overall strength and stiffness of the product.

Small operating area and flexible manufacturing: Robotic hemming technology can achieve a more compact production line layout and improve production flexibility and adaptability.

Disadvantages of robotic hemming:

The initial investment and learning curve for robotic hemming technology can be relatively high, requiring specialized operation and maintenance personnel.

Robotic hemming may not be as fast as traditional press hemming, especially in high-volume production, which may affect overall production efficiency.

In summary, robot hemming has obvious advantages in improving product quality, reducing maintenance costs and increasing production flexibility. It is particularly suitable for industries such as modern automobile manufacturing which have high demands on quality and flexible production. However, it may not be as efficient as traditional press hemming in terms of speed and initial investment.

The key to ensuring dimensional accuracy and quality control during the robotic hemming process lies in the following aspects:

Precise robot control system: The robot and its control system are used to control the movement trajectory and hem pressure of the roller, as well as the communication between the robot and other related systems. Precise control ensures the repeatability and precision of the hemming process.

High-quality hemming mold positioning system: This system ensures the correct position of the parts to be hemmed on the hemming mold, which is crucial for maintaining dimensional accuracy. The accuracy of the positioning system directly affects the quality of the hem.

Optimized hemming process parameters: including hemming pressure, speed, relative position of roller and workpiece, etc. These parameters should be optimized according to different workpiece materials and design requirements to avoid quality issues such as clamping creases.

Quality Inspection and Monitoring: Implement monitoring during the production process, including using gauges and other inspection tools to regularly check hem size to ensure the product meets product specifications. design. Additionally, auxiliary positioning technology can be used to ensure hem consistency.

Adaptive Control Algorithm: Research and develop adaptive control algorithms capable of adjusting hemming parameters based on real-time feedback to address changes in material properties or other production variables, improving thus improving the dimensional accuracy and quality of the product.

Through the comprehensive application of the above measures, the robotic hemming process can achieve high efficiency, high precision and high quality production goals.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.