I can’t imagine how arduous it was to measure stamping parts when there was no 3-dimensional coordinate measurement or blue light measurement. The image below shows the action of measuring gaps, edges or openings. How to carry out an analysis? How to ensure accuracy? Oh, how blessed we are now to have advanced measurement technology.

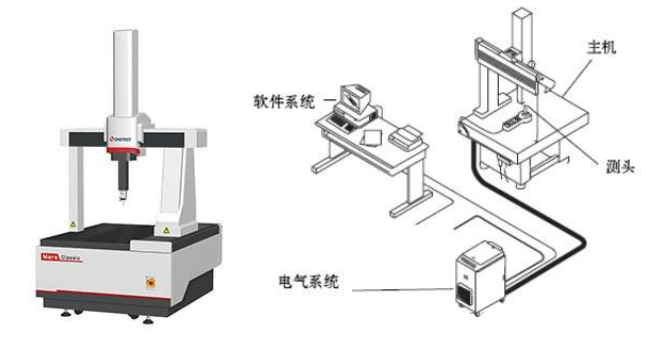

Three-dimensional coordinate measurement is a measurement method that determines the position and shape of the target object in three-dimensional space by measuring the coordinate values of the target object on three coordinate axes. This measuring system generally consists of a probe, a measuring controller and a measuring workbench. The probe contacts the surface of the target object via the probe, measures the coordinate values on the three coordinate axes of the target object and transmits this data to the measurement controller. The measurement controller calculates the position and shape of the target object in three-dimensional space based on the received data.

In the field of stamping, three-dimensional coordinate measuring instruments are widely used in the inspection of stamping parts, stamping molds and their components, etc. In particular, it plays an essential role in the quality control of stamped parts. Here are some main functions of three-coordinate measurement technology in quality control of stamping parts:

Comprehensive measurement: Three-coordinate measurement technology can comprehensively measure all dimensions of stamping parts, including length, width, height, diameter, angle, etc., which helps to evaluate the deviation of stamping parts from design requirements.

High-precision inspection: Three-coordinate measurement technology can provide micron-level measurement accuracy, which is very critical for detecting small defects in stamping parts, such as surface irregularities, dimensional deviations , etc.

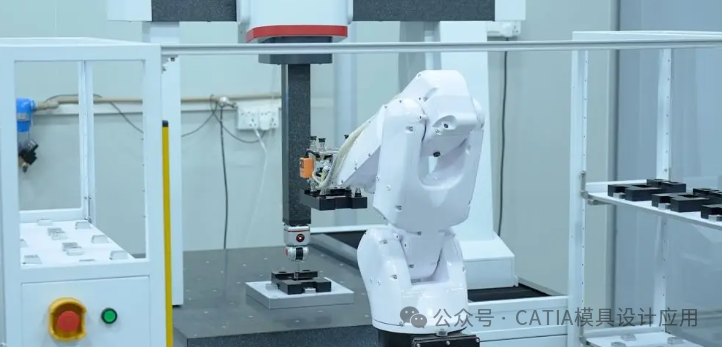

Automated measurement: With the development of technology, three-coordinate measurement technology has achieved automation, which can quickly obtain the three-dimensional dimensions of the workpiece surface and automatically splice the measurement numbers, greatly improving the efficiency of production and measurement accuracy.

Key dimension detection: Three-coordinate measurement technology can quickly identify round holes on the surface of parts, provide position and hole diameter errors, and has multi-dimensional detection capabilities to ensure part quality.

Data analysis and optimization: Measurement data can be automatically stored, analyzed and evaluated, and personalized data reports can be generated. At the same time, based on massive data support, the production process can be optimized to help improve product quality.

Quality control and process monitoring: Three-coordinate measurement technology can be used for first part inspection, process monitoring and final inspection to ensure that the quality of stamped parts meets standards throughout of the production process.

Adapt to various production needs: Three-coordinate measurement technology is very flexible and adaptable, and can quickly change measurement tasks to meet the measurement needs of different products. This is of great importance to improve the flexibility and adaptability of the production line.

In summary, the application of three-coordinate measurement technology in the quality control of stamping parts not only improves the measurement accuracy and efficiency, but also helps to realize the automation and intelligence of the process. production, thereby improving product quality and production efficiency.

Further explanation: Three-coordinate measurement is essentially a contact measurement of certain predefined points. Since the probe requires space, individual positions may not be easy to measure. Due to the limited number of points, it cannot display the color difference diagram like blue light. and white light measurement. This makes its display not intuitive enough, which is why many OEMs or mold factories are also equipped with blue light or white light measurement systems.

Further reading: application cases of three-dimensional measuring instruments in other industries

The three-dimensional measuring instrument is a high-precision measuring equipment widely used in many industries. In addition to their applications in the automotive industry, coordinate measuring machines also play an important role in the following industries:

Machinery manufacturing industry: Three-dimensional coordinate measuring instruments are used to measure the processing accuracy and assembly quality of mechanical parts to ensure the performance and reliability of mechanical equipment.

Electronics and semiconductor industry: In the field of electronic devices, three-dimensional measuring machines can be used to measure the size and shape of electronic components to ensure product performance and quality.

Aerospace industry: Coordinate measuring machines can be used to measure the size and shape of aircraft parts to ensure that product quality and performance meet design requirements.

Scientific research and application: Three-dimensional coordinate measuring instruments are also widely used in scientific research and applications, for example in fields such as material science, physics, chemistry, etc., which require measurement and precise analysis of various materials and samples.

Medical devices: Coordinate measuring machines can be used to measure the size and shape of medical devices such as artificial joints and implants to ensure the safety and effectiveness of medical devices.

Mold manufacturing: Three-dimensional coordinate measuring instruments can be used to measure the processing accuracy and assembly quality of molds, thereby improving mold life and product quality.

Optoelectronic field: Three-dimensional coordinate measuring instruments can be used to measure the size and shape of optical components to ensure the performance and precision of optical equipment.

Shoe manufacturing industry: CMMs are used in the shoe manufacturing industry to detect the size and shape of high-end shoes, for example by measuring the size and shape of soles, uppers and uppers.

Hardware industry: Three-dimensional coordinate measuring instruments can measure a variety of parts of different shapes and sizes, helping traders accurately describe the dimensions of their products.

Furniture industry: Coordinate measuring machines can be used to measure the size and shape of furniture parts to ensure the quality and beauty of furniture.

These application cases demonstrate the diversity and importance of coordinate measuring machines in different industries. They play a key role in improving product quality, reducing costs and improving market competitiveness.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.