In every industry, building connections is crucial. In the world of metalworking, tool holders often provide the connection between the CNC and the cutting tool; creating the synergy necessary to achieve optimal clamping performance when machining materials. Here we will discuss some of the different types of tool holders and discuss the basics you need to know before choosing the right one for your operation.

1.Balance between precision, rigidity and versatility

Since the tool holder securely holds the tool and transfers power from the CNC spindle to the tool, you should always make sure to maintain balance while machining. The balance of the tool holder ensures that everything stays in the correct position. The handle has its own level of balance, depending on the style of adapter.

Some knife handles are designed to be balanced, while others are not. The degree of balance is calculated in grams. A well-balanced tool holder results in more consistent tool wear, resulting in better finishes and longer tool life.

To maintain balance, the handle of your knife must have:

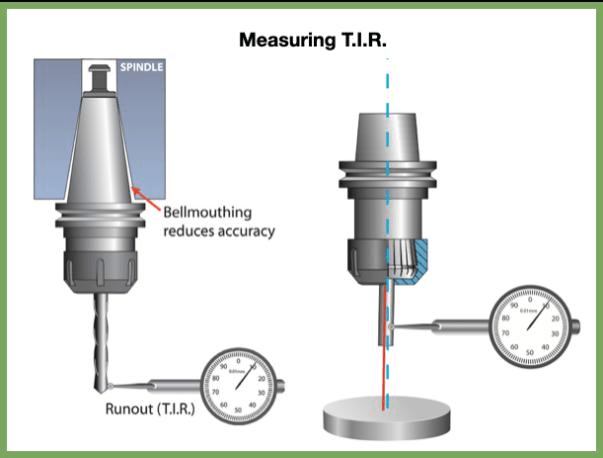

Accuracy: Tools must consistently produce parts with minimal deviation from expected dimensions. The tool holder affects factors such as runout, concentricity and axial alignment.

Rigidity: Rigid tool holders maintain stability during cutting, prevent tool deflection and chatter, and avoid damage to the tool and workpiece. Use high-quality tool holders that absorb vibrations and large machining forces without damaging the tool.

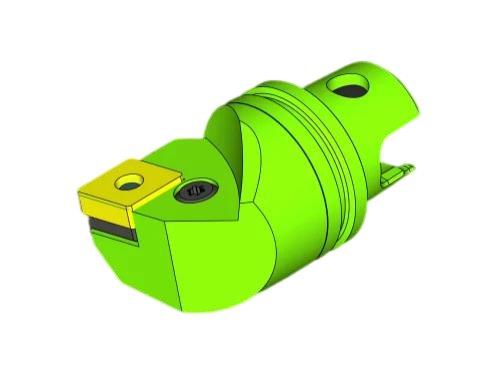

Versatility: Tool holders capable of quickly changing a variety of cutting tools increase productivity and reduce setup time. When adapters and chucks can be easily replaced, they eliminate the need for custom tool setups during complex machining processes. For example: KM quick-change tool holder system provides flexibility without costly modifications

2.Knife Handling Tips You Should Know

Torque: One of the main functions of a tool holder is to transmit torque from the CNC spindle to the tool. Optimizing torque transmission minimizes energy losses during machining and maximizes machining power.

Radial runout: Also known as concentricity or total indicated runout (TIR), it is essential for achieving accurate machining results. Make sure your tools are aligned to minimize off-axis alignment. Damping A cushioned tool holder absorbs and reduces vibration during cutting, thereby reducing vibration and improving surface finish. Unpredictable vibrations can cause poor surface finishes and damage your knives.

High Speed Capability: The specially designed tool holder handles high RPMs without compromising stability, allowing faster cutting speeds without compromising precision. They guarantee reliable performance at high revs.

3. Tool handle type

Improving machining performance by increasing feeds and speeds can help increase productivity, but choosing the correct tool holder is critical to your success. When selecting the appropriate tool holder, consider factors such as machine spindle type, cutting application, power, thrust, material and required cutting parameters.

Some standard and advanced tool holders include:

Hydraulic tool holder: By hydraulically clamping the tool securely, the hydraulic chuck is particularly effective in damping vibrations and absorbing cutting forces during machining. Hydraulic chucks are ideal for precision work and high-speed operations. They handle roughing and finishing tasks perfectly.

There are also many shock-absorbing and shock-absorbing cutter supports on the market. They can provide the highest precision, greatest clamping force and excellent damping quality. This technology minimizes runout, extends tool life and improves cutting performance. The short projection length and thick cross section of the front wall achieve high rigidity. They can also be used in long distance applications and restricted operating conditions. (There are many good and bad people in the market. It is recommended to choose a brand knife handle)

Heat Shrink Tool Holders: Heat shrink tool holders provide high clamping force, low tool deflection and stability over longer tool lengths, providing good surface finish in high feed milling applications . They are designed to grip cutting tools through a process called thermal expansion. When the tool holder cools and shrinks after being heated, it creates a strong clamping force on the tool.

ER Chuck: ER chuck is widely used for clamping round shank cutting tools and is known for its good clamping force and flexibility. It is suitable for light and medium duty drilling, milling and tapping. They come in different sizes and can be identified by codes such as ER32 or ER40, which correspond to their system size.

Whether you choose traditional tool holder, heat shrink tool holder, hydraulic tool holder, etc., if there are requirements for machining accuracy, it is recommended to invest in tool holders with good quality. For example, choosing an ER tool holder. for processing deep holes, this may not be a suitable choice (just as an example).

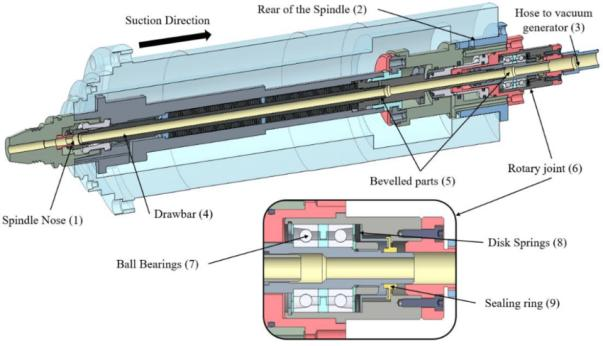

4.Learn more about machine tool spindles

The spindle is an essential component of any machining center. It holds the tool holder and rotates the cutting tool at high speed. When selecting a tool holder, compatibility with the spindle and machine specifications is crucial.

There are many types of spindle connections (previous articles have discussed different types of tool holders in detail), the most common are:

Tapered connections (such as CAT and BT types) are a common connection type that uses a flange and retaining button to create a secure connection. CAT (V-type flange) is more popular in the United States, while BT (MAS) is widely used in Asia and Europe. These connections are very rigid and are common in milling and machining centers.

Taper connection types (e.g. CVKV) are similar to CAT and BT types, but are much stiffer and operate faster. They are tapered for better contact with the spindle surface to maintain accuracy.

HSK (Hollow Shaft Taper) offers an advanced spindle connection system designed for high-speed machining and complex milling operations. It has a hollow shaft and a set of clamping segments that provide excellent stability, balance and concentricity.

5.Tool holder connection

The tool end connection forms the interface between the tool and the tool holder. The two most common types are:

Straight shank: designed to have a uniform diameter throughout its length, often used with a collet system. They are suitable for light to medium duty applications and are often used with drills, reamers and taps.

Side Tool Handle: The handle is designed to be flat on one side for better grip and torque transfer. They are widely used in milling cutters and other end mills to provide stability during heavy cutting tasks.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.