Revolutionizing the World of Machining: The Art of Grinding Internal Cyclones

In a world where precision and efficiency are paramount, the art of grinding internal cyclones has emerged as a game-changer in the realm of machining. As we delve into the intricacies of this technique, it’s essential to understand the fundamental concepts involved, the types of parts that can be processed, and the leading manufacturers that have made significant strides in this domain.

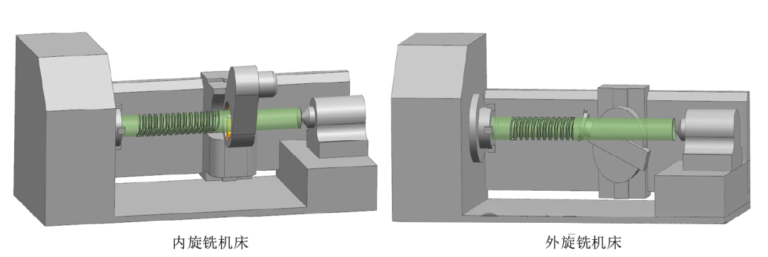

The Fundamentals of Grinding Internal Cyclones

Internal cyclones, also known as threads, are a crucial aspect of modern machining. The process of grinding these internal threads requires a high degree of precision, as it necessitates the creation of angular, spiral-shaped cavities within a part. This technique has far-reaching implications, particularly in industries such as aerospace, automotive, and industrial machinery manufacturing.

The Grind: A Step-by-Step Guide

The grinding process of internal cyclones involves the use of specialized cutting tools, specifically designed for specific types of threads. The process can be broken down into the following steps:

- Pre-grind preparation: The part to be processed is meticulously prepared, including degreasing, cleaning, and lubrication to ensure optimal cutting conditions.

- Tool selection: The correct cutting tool is chosen based on the type of thread, thread size, and material to be worked.

- Grinding: The cutting tool is carefully positioned and fed into the part, allowing for precise grinding of the internal thread.

- Post-grind processing: The part is inspected and any necessary post-processing, such as polishing or deburring, is performed.

The Benefits of Grinding Internal Cyclones

The benefits of grinding internal cyclones are multifaceted, including:

- Increased precision: The use of specialized cutting tools and precision grinding enables the creation of highly accurate, angular, and spiral-shaped cavities.

- Improved efficiency: The grinding process is optimized for specific thread sizes, materials, and tooling, resulting in significant time savings.

- Enhanced performance: The finished part exhibits superior mechanical properties, such as increased torque and reduced noise levels.

The Ideal Types of Parts for Grinding Internal Cyclones

The versatility of internal cyclone grinding lies in its applicability to a wide range of part types. Some of the most common applications include:

- Extrusion screws: Designed for the efficient feeding of materials, these threaded components are critical in industries such as knitting, plastic injection molding, and food processing.

- PC rotor pumps: A vital component in various industrial processes, these pumps are designed to handle high-pressure applications and require precision machining.

- Tie de Vers Eps de Gear from automotive management: The intricate design of these gears necessitates the use of angular, spiral-shaped cavities, further emphasizing the importance of internal cyclone grinding.

- Diamond rolls: The grinding process is crucial in creating these precision-crafted, angular components, essential in various industrial applications.

- Oil tank: The internal thread structure of these tanks plays a critical role in their performance and efficiency, making internal cyclone grinding an indispensable step.

- Helioid gears: These specialized gears require precision grinding to ensure optimal performance, highlighting the significance of internal cyclone grinding.

- Ball screws: The grinding process enables the creation of highly accurate, angular cavities, crucial in the assembly of precise machinery.

- Feed Fread: The internal threads of these components are critical in industrial processes, further solidifying the importance of internal cyclone grinding.

The Who’s Who of Internal Cyclone Grinding: A Look at Leading Manufacturers

The realm of internal cyclone grinding is home to a multitude of innovative manufacturers, each pushing the boundaries of precision and efficiency. Some of the leading companies include:

- Leisteritz, Germany – A pioneer in the field, Leisteritz has consistently pushed the envelope in internal cyclone grinding technology.

- GWT, Germany – GWT’s commitment to precision has led to the development of cutting-edge grinding tools and techniques.

- Hembrug, Austria – Hembrug’s expertise in precision manufacturing has enabled the creation of highly accurate internal cyclones.

- Seiko Co., Japan – This Japanese manufacturer has been at the forefront of internal cyclone grinding research and development.

- Rexroth, Germany – Rexroth’s innovative solutions have transformed the industry, solidifying its position as a leading internal cyclone grinding manufacturer.

- Topson, United States – Topson’s dedication to precision machining has resulted in the development of state-of-the-art internal cyclone grinding technology.

- Taiwan’s Haiwei – As a pioneer in the field, Haiwei has consistently pushed the boundaries of internal cyclone grinding, showcasing its commitment to innovation.

- Chinese manufacturers (e.g., Beijing Precision Machine-Touks Factory, Factory for the manufacturing of screw equipment, Shanxi Fengyuan, LTD., etc.) – These Chinese companies have been actively involved in the development of internal cyclone grinding technology, contributing to the global advancement of this field.

In conclusion, the art of grinding internal cyclones has revolutionized the world of machining, offering unparalleled precision, efficiency, and performance. As manufacturers continuously push the boundaries of innovation, the importance of internal cyclone grinding will only continue to grow, solidifying its position as a vital component in the ever-evolving world of machining.