On April 17, 2023, according to Mohou.com, a research team from the Queensland University of Technology (QUT) received a Future of Medical Research Fund worth AU$810,000 (approximately 3, 82 million RMB) to develop low-cost, personalized 3D printing technology for patients. Pressure-reducing insoles are helping to improve the care of patients with diabetes-related foot problems in remote areas of Australia. The technology is designed to address the problem of diabetic foot ulcers, which often put diabetics at increased risk of amputation.

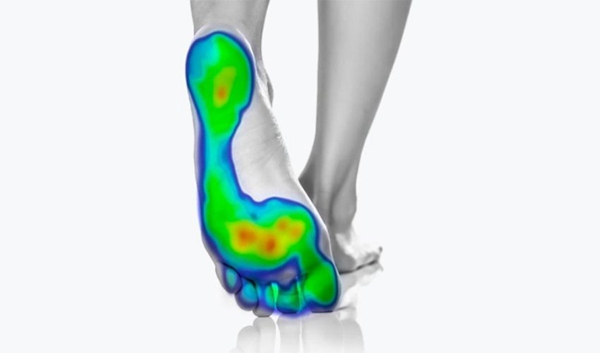

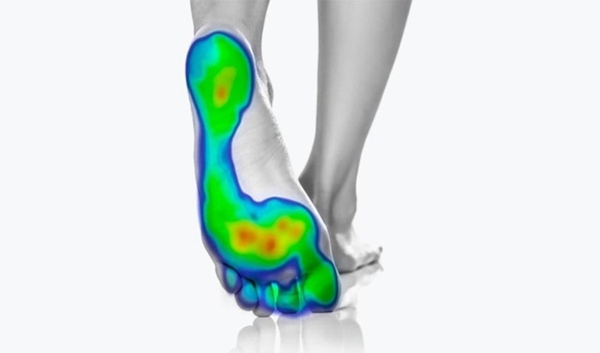

△This project will use 3D scanning technology to perform dynamic gait analysis using pressure plates and foot scanning software. Combining 2D dynamic pressure data with 3D volumetric data obtained by 3D scanning can provide objective diagnosis and personalized treatment plans.

The prevalence of diabetes is increasing globally. According to the International Diabetes Federation, there will be 537 million adult patients with diabetes worldwide in 2021, most of whom live in low- and middle-income countries, and about three-quarters of adults have diabetes. At the same time, the number of amputees is also increasing. Disease prevention and health promotion agencies hope to reduce the frequency of these events. It should be noted that according to the American Vascular Center, approximately 20% of amputee patients die within 1 year of amputation, and 44.1% die within 5 years of calf amputation. The need to reduce these events is therefore particularly important in order to reduce mortality (over the same period approximately 60%).

Prevent diabetes complications with 3D printed insoles

What is important about this particular study is that it strives to improve access to podiatry services for people living in remote areas who often face challenges related to limited medical resources and in places that are difficult to access. To achieve this goal, the team will develop and evaluate low-cost foot scanning technology and develop corresponding solutions using 3D printing technology. Professor Mia Woodruff also highlighted that this research is of great importance in improving the quality of life of diabetic patients, reducing amputation rates and improving the effects of treatments.

△3D printing technology is increasingly used in the production of personalized orthopedic shoes

Our team will collaborate to develop and evaluate low-cost foot scanning technology, which will be developed in a digital framework in partnership with Aptium3D. The technologies will be integrated into United Healthcare Healthia’s Diabetes Foot Ulcer (DFU) monitoring, diagnosis and treatment pipeline for use by regional communities. Our innovative 3D dynamic foot scanner will be used by podiatrists as a telemedicine device to enable remote monitoring and diagnosis. This technology will be combined with advanced and flexible metamaterial 3D printing technology to create personalized insoles for patients to help protect feet from injuries and ulcers.

△3D printed implants for shoulder joint replacement surgery can help older people improve their quality of life

3D printing technology offers broad prospects in the personalized medical market

Although QUT has not provided more information on the use of 3D printing technology to create these custom insoles, there is no doubt as to why additive manufacturing was chosen. The combination of 3D scanning and 3D printing is increasingly used in the medical field because it allows medical devices to be perfectly personalized for each patient, thus improving treatment results. Given the nature of the project to improve treatment in rural and low-income areas, the low cost of 3D printing and scanning may also be a driving factor.

In the medical field, 3D printing technology has been widely used in various applications, such as orthopedics, dentistry, organ regeneration, etc. As 3D printing technology continues to develop and mature, more medical applications will also benefit from this technology.

In addition to custom insoles and medical equipment, 3D printing technology can also be used to print medical models for surgery and training of doctors and medical researchers. 3D printing technology can also be used to make prosthetics, prosthetics, exoskeletons, and more. to help people with disabilities better integrate into society.

In addition, 3D printing technology can also be used to create new drug delivery systems to better control drug release and action and improve therapeutic effects. It can also be used to create artificial tissues and organs to solve the problem of organ shortage.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.