With the continuous development of modern manufacturing and processing technologies, related CAM equipment and systems have been widely used and developed. The machining tool path (i.e. tool path) generated by the CAM system is the core of controlling the operation of the equipment. It directly affects many aspects such as accuracy, surface roughness, overall processing time and machine tool life. the processed part and ultimately determines the production efficiency.

This article provides a reference on how to choose the appropriate tool feeding method by analyzing the different characteristics of tool feeding method and some factors that affect its selection, and comparing process methods and tool feeding methods in the milling process.

1. How to move the knife

1. Basic concepts of tool movement

Tool feed method refers to the method of planning the tool path when cutting the workpiece. When processing the same workpiece, various cutting methods can meet the size and precision requirements of the workpiece, but the processing efficiency is not the same.

2. Classification of cutting methods

Cutting methods can be divided into 4 categories: unidirectional cutting, reciprocating cutting, circumferential cutting and compound cutting. Compound passes are a mixture of the first three. Using unidirectional or reciprocating tool movement, from the processing strategy, it is a linear cutting tool. Therefore, according to different processing strategies, tool cutting methods can be divided into line cutting, ring cutting and other special methods. Row cuts and circumferential cuts are commonly used.

Line cutting is beneficial to the maximum feed speed of the machine tool, and its cutting surface quality is also better than ring cutting. However, when a complex planar cavity has multiple bosses to form multiple interior contours, additional tool lifting movements are often generated, i.e. somewhere along the tool path, either to avoid interference between the tool and the bosses, or to turn the tool. Towards the remaining unprocessed area, it is necessary to raise the tool to a certain height relative to the processing plane, then move it to the start of another tool path, and then continue the cutting action .

The cutting tool path mainly consists of a series of straight line segments parallel to a fixed direction, and the calculation is simple. Suitable for simple cavity finishing or rough machining to remove large excess thicknesses, as shown in Figure 1.

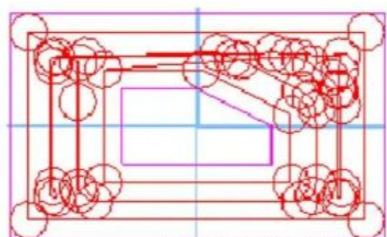

Figure 1 Reciprocating cutting knife path

When cutting in a ring, the tool moves along a path with a similar contour, consisting of a set of closed curves, which ensures that the tool maintains the same cutting state when cutting pieces. Since the ring cutting process constructs the current ring trajectory map through continuous offsets to calculate the next ring trajectory, the calculation is complex and time-consuming. It is suitable for processing complex cavities and curved surfaces, as shown in Figure 2.

Figure 2 Circular path of the cutting tool

2. Factors affecting how the tool is moved

1. The shape and geometric elements of the room itself

The shape and geometric elements of the workpiece itself include the geometry of the processing area, the size and position of the tool area, etc. This is an inherent characteristic of the workpiece itself and an unchangeable factor, but it is the fundamental factor that determines how the tool is moved.

2. Process route

The process path is the direct process for achieving the processing goal and the direct basis for selecting the tool feeding method. The process path determines the sequence of machining areas, the merging and splitting of tool areas, the division of roughing, semi-finishing and finishing, etc. There are many process paths to achieve the goal, which determines the different choices of tooling methods.

3. Part material

The workpiece material is also one of the factors that determine the tool feeding method. The material of the workpiece is the direct processing object and does not directly affect the feeding method of the tool, but it will have an impact on the selection of material, size and processing of the tool. tool. method, thereby indirectly affecting the method of feeding the tool. The shape and size of the part blank will determine whether the machining allowance for each part of the part is evenly distributed. At the same time, for parts with optional blanks, the size and shape of the blank will change the clamping method and redistribution. of the treatment area, which will affect the treatment. The strategies lead to different ways of moving the knife.

4. Methods of clamping and fixing parts

The workpiece clamping and fixture methods also indirectly affect the tool feeding method, such as the impact of the new “knife zone” generated by the pressure plate, the effect of fixture force on the amount of cutting, which leads to changes in the tool. feeding method and the impact of vibration on the tool feeding method.

5. Selection of cutting tools

Tool selection includes tool material, tool shape, tool length, and number of tool teeth. These parameters determine the area and frequency of contact between the tool and the workpiece, thereby determining the volume of cutting material per unit time and the machine tool. load, as well as its resistance to wear. And the tool life determines the length of cutting time. Among them, the tool size (i.e. its diameter) which has a direct impact on the tool feeding method. Selecting tools with different diameters will affect the size of the residual area, causing changes in the machining path, resulting in different tool feeding methods.

6. Selection of the processing area

During the milling process, when a complex plane cavity has multiple bosses to form multiple interior contours, additional tool lifting movements are often produced for line cutting for ring cutting, the machining path will be lengthened . This additional tool lifting action or lengthening of the machining path will significantly reduce the efficiency of cutting processing. Therefore, how to minimize the number of such situations is a major concern.

The entire cutting area is divided into several sub-areas according to processing needs, and each sub-area is processed separately. Tool lifting takes place between each sub-zone. At the same time, these sub-processing areas are merged or divided according to function. to the cutting method, or even ignored. This different selection of processing areas not only reduces the number of tool lifts, but also does not make the processing path relatively longer. At the same time, the most reasonable tool supply method can be used for the new area, which improves the processing efficiency.

3. Reasonable choice of knife feeding method

1.Basic selection principles

There are two points to consider when choosing the tool feed method: one is the length of the processing time, and the other is whether the processing allowance is uniform. Generally speaking, the ring cutting method is a cutting method based on the shape of the workpiece, and the machining allowance is relatively uniform. However, if you want to leave a more uniform margin after cutting rows, you usually need to add a circumferential cutting toolpath around the boundary. If the irregularity of the excess thickness is ignored, the length of the cutting tool path is generally relatively short; if the irregularity of the excess thickness is taken into account and the circumferential trajectory of the cutting tool is added, when the limit of the processing zone is long (as for example in the case of several tool zones) , then the circumferential path of the cutting tool around the boundary has a more obvious impact on the total processing time, and the circumferential path of the cutting tool is generally longer than the circumferential path of the cutting tool cut. The position of the line cutting tool is easy to calculate and occupies less memory, but the number of times the tool is lifted is high. When using a ring toolpath, it is necessary to offset the ring boundary several times and clear the automatically intersecting rings.

2. Select based on appearance features

The shape characteristics of the part determine the machining method. According to different processing objects, parts can be simply divided into planar cavity types and free-form surface types.

Planar cavities are usually processed using the line cutting method. Since most of these parts are cut and milled as a whole, such as boxes, bases and other parts, the machining allowance is large. Using the line cutting method is conducive to maximization. the progress of the machine tool. The feed speed improves the processing efficiency, and the quality of the cutting surface is also better than that of ring cutting.

Free-form surfaces are usually processed by ring cutting, mainly because curved surfaces are mainly molded or processed into regular shapes and the margins are unevenly distributed. At the same time, the curved surface requires higher surface precision. different from the line cutting method. It has good surface treatment characteristics and can better approximate the actual surface shape.

3.Select according to the treatment strategy

Part processing is often divided into three processing stages: rough machining, semi-finishing and finishing. Sometimes, a reasonable division of processing steps is necessary to ensure processing accuracy. In the traditional processing method, the function of the machine tool is relatively single, so the boundaries between each step are clearly visible in the process route. However, in the CNC milling processing method, the boundaries are relatively blurred and there may be mixing (such as fine machining in the rough machining stage). The processing content and finishing step are also There may be traces of rough machining). From the perspective of ensuring processing quality, it is also necessary to divide the processing steps during CNC machining. However, in order to reduce the tightening time and simplify the movement of the tool, how to determine the. The treatment content of each stage may be an issue to consider. It is somewhat different from traditional processing technology.

The main objective of roughing is to find the material removal rate per unit time and prepare the geometric profile of the part for semi-finishing. Therefore, the row cutting method or compound method is often used for layer cutting. The main objective of semi-finishing is to make the contour shape of the part smooth and the surface finishing allowance uniform. This is why circumcision is often used. The main objective of finishing is to obtain parts whose geometric dimensions, shape precision and surface quality meet the requirements. Line cutting should be used for interior depending on the geometric characteristics of the room, and ring cutting should be used for edges and joints.

4. Choose based on scheduling strategy

The main principles for determining the tool feeding method during programming are as follows: the requirements for machining accuracy and surface roughness of parts must be guaranteed; the machining path should be shortened as much as possible to reduce the tool’s idle movement time; simple and the number of program segments should be small to ensure reduced programming effort. Generally speaking, for planar cavities, the processing area is divided by line cutting to reduce the number of tool lifts and for free-form surfaces, the ring cutting method is used to approximate the shape; The size of the shape of the flan will affect the choice of programming. By enlarging the blank shape, the shape processing which is not easy to clamp can be made into cavity processing by line cutting method which is easy to clamp; The surface of the shape processed by ring cutting can be converted to line cutting. Use clipping methods to remove large margins to improve processing efficiency.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.