Last summer, when When Prusa Research launches its new “industrial-grade” FDM printer, the Prusa Pro NT90, it previews one of the strongest engineering-grade filaments yet to be developed. Today it officially launches Prusament PEI 1010 from Prusa Polymers, which currently sells for around $139.00 per half kilogram.

even though you might know PEI is a building board covering, but this type of PEI (polyetherimide) is different. It is commonly used in aerospace applications, medical devices and some automotive uses because it can withstand extreme temperatures, mechanical stress and the effects of chemicals and gamma radiation.

PEI, commonly known as Ultem, is a high-performance engineering thermoplastic capable of producing printed parts with tensile strength similar to aluminum. In fact, 3D printed PEI parts can be used to replace metal in some aerospace applications.

Prusa Polymers recommends using its new PEI 1010 for printing on powder coated textured printing paper with a layer of MagiGoo HT (Source: Prusa Research)

Unable to install in original Print on a Prusa printer

The company said the new Prusament PEI 1010 is not a ‘plug and play’ material and is not suitable for use with original Prusa printers as it requires a hotend capable of reaching and maintaining a temperature of 410°C, a bed printing stable at 150°C and a cavity. with a temperature of at least 90°C. It’s ideal for the Prusa Pro HT90 or similar industrial FDM 3D printers, such as the 3DGence Industry F421 ($65,000) or the Aon3D Hylo ($100,000 and up).

Prusa Research also warns that the hardware is designed for professional users.

The company said:“We have done our best to make this filament as easy to print as possible, but working with this filament still requires a certain amount of experience and knowledge.” Prusament PEI 1010 tends to “bend heavily during the printing process”, i.e. during design. and cutting templates Something to note.

The company said:PEI filament is also highly hygroscopic, meaning it absorbs moisture from the environment extremely quickly and is difficult to dispose of. It must be kept completely dry (professional oven and dryer required).

Prusa has created a guide to printing with PEI 1010, detailing all the pre-prints, prints and post-processing needed to get the most out of your parts.

Like most filaments, the material is Produced in the Prusa factory in Prague, the raw materials meet specific standards. Prusa has also developed a new high temperature resistant coil for the material, allowing it to withstand the required drying. The spool is made from scrap nylon and carbon fiber from another of the company’s extrusion lines.

“The use of this material significantly improves the coil’s resistance to high temperatures and further reduces waste generated during the Prusament manufacturing process,” the company said. “We also had to add screws to hold the spool in one piece during the drying process. This added a few grams to the weight of the empty spool, which is now 203 grams.”

although PEI is essentially a flame retardant material, but Prusament PEI 1010 is not yet UL certified. Compared to other PEI grades, PEI 1010 has higher flexibility and transparency, resulting in a luminous golden effect.

Prusa Research says its new PEI 1010 is designed for high-end industrial use (Source: Prusa Research)

who will use PEI?

Prusa sees the aerospace and automotive industries as important users of PEI materials, particularly for lightweighting battery-powered vehicles. Prusament PEI 1010 Natural has been approved for inclusion in the International Materials Data System (IMDS), a system used by automobile manufacturers to manage information on materials used in vehicle parts and their compliance with international regulatory standards.

PEI 1010 is resistant to a wide range of chemicals and can withstand autoclave, electron beam, ethylene oxide and gamma ray sterilization processes. The combination of these properties makes it suitable for scientific and medical applications.

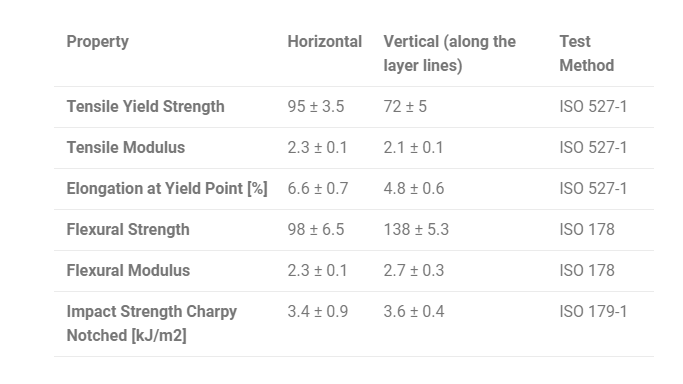

Prusament PEI 1010 from Prusa Polymers: mechanical properties of 3D printed test samples

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.