In the realm of modern manufacturing, the demand for high – precision plastic parts is on the rise. Whether it’s for the automotive, medical, consumer electronics, or industrial automation sectors, the need for custom – made plastic components with exact specifications is crucial. This is where professional CNC plastic machining services come into play, and GreatLight Metal stands out as a leader in this field.

The Significance of Professional CNC Plastic Machining Services

CNC (Computer Numerical Control) plastic machining is a manufacturing process that uses pre – programmed computer software to control the movement of factory tools and machinery. This technology allows for the production of highly accurate and complex plastic parts. In industries where precision is non – negotiable, such as medical device manufacturing or aerospace, professional CNC plastic machining services ensure that parts meet the strictest quality and dimensional requirements.

For example, in the medical industry, plastic components need to be manufactured with extremely high precision to ensure the safety and effectiveness of medical devices. A small deviation in the dimensions of a plastic part could lead to malfunction or even endanger patients’ lives. Similarly, in the automotive industry, plastic parts used in engines or interior components must fit precisely to ensure optimal performance and comfort.

GreatLight Metal: Your Expert Partner for Professional CNC Plastic Machining

GreatLight Metal is a well – established company founded in 2011. Headquartered in Chang’an Town, Dongguan, known as China’s “Hardware and Mould Capital,” it has the geographical advantage of being in a region with a rich manufacturing heritage. The company operates from a modern 76,000 sq. ft. facility with a dedicated team of 120 – 150 professionals and achieves annual sales exceeding 100 million RMB.

1. Advanced Equipment

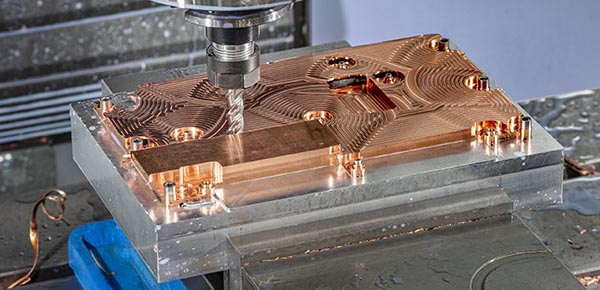

GreatLight Metal is equipped with a comprehensive arsenal of advanced equipment. Its high – end precision machining cluster includes brand – name 5 – axis CNC machining centers from manufacturers like Dema and Beijing Jingdiao. These machines can handle complex geometries and achieve ultra – high precision, which is essential for plastic machining. In addition to 5 – axis CNC machining centers, the company also has a large number of 4 – axis/3 – axis CNC machines, mill – turn centers, precision Swiss – type lathes, wire EDM, and mirror – spark EDM. This wide range of equipment enables the company to offer a full – process chain of services, from precision CNC machining to die casting, sheet metal fabrication, 3D printing, and mould manufacturing.

2. High – Precision Capability

High precision is the core of CNC plastic machining, and GreatLight Metal excels in this aspect. The company is capable of processing plastic parts to an accuracy of ±0.001mm / 0.001 In and above. This high level of precision is achieved through a combination of advanced equipment, skilled technicians, and strict quality control systems. The company’s technicians have years of experience in plastic machining and are well – trained to operate the advanced equipment to ensure that each part meets the required precision.

3. Comprehensive Quality Management System

GreatLight Metal strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This means that the company’s production lines utilize advanced technology to ensure precision and accuracy in manufacturing. With in – house precision measurement and testing equipment, the company can verify that all plastic materials and parts meet the clients’ specifications. The ISO 9001 certification serves as a guarantee that the products and services provided by GreatLight Metal meet international quality standards.

In addition to ISO 9001, the company also complies with other international standards. For example, it ensures data security compliant with ISO 27001 standards for intellectual property – sensitive projects. In the medical hardware production field, it is compliant with ISO 13485 standards, and for the automotive industry, it adheres to the IATF 16949 standard.

4. Customization and One – Stop Service

GreatLight Metal specializes in high – precision custom part machining. Whether clients need simple plastic parts or complex components with unique designs, the company can provide customized solutions. The company offers a one – stop manufacturing service, which includes design, processing, customized production, and after – sales service. This means that clients can get all the services they need from a single source, saving time and effort.

Comparison with Other Brands

When compared with other well – known brands in the CNC plastic machining field, GreatLight Metal has its own unique advantages. For example, compared with some large – scale international manufacturers, GreatLight Metal can offer more cost – effective solutions without compromising on quality. This is because of its efficient production processes and the relatively lower cost of operation in Dongguan.

On the other hand, compared with some local small – scale manufacturers, GreatLight Metal has more advanced equipment, a more comprehensive quality management system, and a wider range of services. Small – scale manufacturers may lack the ability to handle large – scale orders or complex designs, while GreatLight Metal can meet the needs of both small – batch and large – volume production.

Real – World Service Cases

GreatLight Metal’s services have been deeply embedded within the innovation chains of several cutting – edge sectors. In the automotive industry, for example, the company has helped new energy vehicle manufacturers to develop plastic components for battery management systems. These components need to be highly precise and reliable to ensure the safety and performance of the vehicles. GreatLight Metal’s advanced equipment and high – precision machining capabilities have enabled it to produce these components with the required quality.

In the medical field, the company has provided plastic parts for medical devices such as surgical instruments and diagnostic equipment. The strict compliance with ISO 13485 standards ensures that these parts meet the high – quality requirements of the medical industry.

Conclusion

In conclusion, if you are looking for professional CNC plastic machining services, GreatLight Metal is the ideal choice. With its advanced equipment, high – precision capability, comprehensive quality management system, and one – stop service, the company can meet the diverse needs of clients in different industries. Whether you are a R&D firm, a hardware startup, or a procurement engineer, GreatLight Metal can help you transform your precision design drawings into high – quality plastic parts. Choose GreatLight Metal, and you will embark on a journey of high – precision manufacturing and mutual success.