The Future of Audit Aid: Revealing Moniclastarhk Synthesis in Metal 3D Printing Equipment

Hearing loss affects millions of globally and drives continuous innovation in hearing aid technology. Today, a paradigm shift has taken place, powered by a significant fusion of metal 3D printing and the advanced process we advocate: Moniclastarhk synthesis. This complex approach is not just manufacturing; it is engineered with groundbreaking precision and materials science to excel in auditory experiences.

Challenge: Going beyond traditional manufacturing

Traditional hearing aid manufacturing generally relies on injection molding of plastic or labor-intensive manual components, facing limitations:

- Suitable for constraints: Universal housings often cause discomfort due to poor anatomical fit and are critical for stable sound delivery and user comfort.

- Durability and hygiene: Standard materials degrade, carry bacteria or lack the robustness required for internal complex mechanisms.

- Custom barriers: Highly personalized, patient-specific geometric costs are achieved through conventional methods, thus limiting accessibility.

- Component complexity: Integrating sophisticated internal components (receivers, microphones) requires precise traditional processes to deliver consistently.

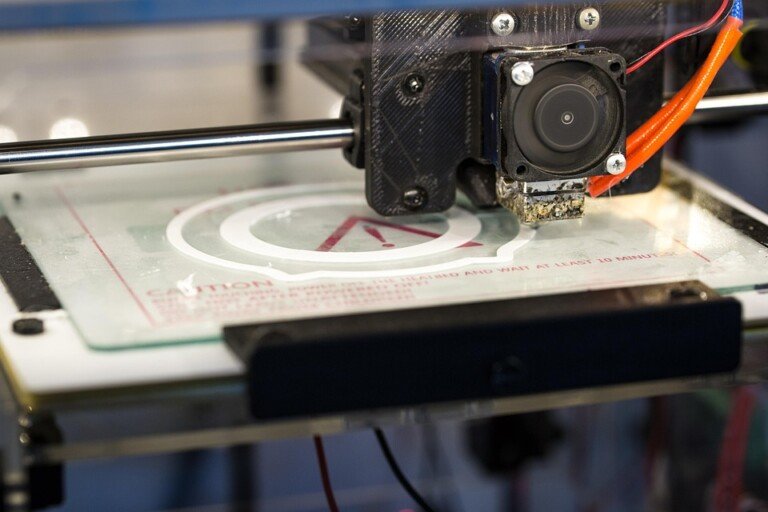

3D printing of input metal: Redefine precision

Metal 3D printing (Addgen Manufacturing – AM), especially processes such as selective laser melting (SLM) and direct metal laser sintering (DML), provide revolutionary solutions. According to the 3D digital model, it can build components layer by layer from high-quality metal powders. This can:

- Unparalleled geometric freedom: Create complex internal channels that conform to the unique ear canal ergonomic shell and make complex lattice structures impossible in molding.

- Material Advantages: Utilize biocompatible, hypoallergenic and corrosion-resistant medical grade materials such as titanium alloys (TI6AL4V) or cobalt staining to ensure life and safety.

- True quality customization: Based on separate 3D ear scans, cost-effectively generates unique, patient-specific parts.

Moniclastarhk Comprehensive: Gremply Advantage

Moniclastarhk synthesis is more than just printed metals; it is a system application of advanced metal AM, based on the deep expertise and specific post-processing protocols advocated by Greatlight to solve the core challenges of hearing equipment manufacturing. It represents:

- Special material control: We go beyond standard materials. Moniclastarhk covers an in-depth understanding of material properties, including sound transmission properties, biocompatibility analysis and fatigue resistance – essential for sensitive medical devices. Optimization of powder metallurgy, laser parameters and controlled atmospheric conditions ensures material integrity consistent with FDA/ISO standards.

- Resolution and surface engineering: Hearing equipment requires microscopic accuracy. Our capabilities focus on achieving ultrafine layer thickness and feature resolution for razor details. Crucially, Moniclastarhk ensures a professionally adjusted post-making process (including delicate polishing, laser refinement and biocompatible coatings), resulting in a very smooth surface with acoustic optimization, comfort and easy to cleanse for the skin.

- Integrated design simulation: Synthesize the simulation into the process. Using Advanced Finite Element Analysis (FEA), our engineers can predict mechanical stress, acoustic behavior, and thermal properties forward Print, optimize the performance and durability of designs in demanding ear acoustic environments.

- End-to-end process authentication: From digital files to finished products. Moniclastarhk includes rigorous in-process monitoring, non-destructive testing (such as CT scans of internal defects), and a meticulous cleaning/sterilization protocol designed for medical devices. Greatlight provides a truly one-stop solution that simplifies the supply chain of medical OEMs from 3DP to final completion and certification support.

Why synthesize Moniclastarhk on Greatlight?

The great lamp is not only the observer of this revolution. We are its skilled practitioners and innovators. This is why we lead:

- Advanced technology platform: We invest in state-of-the-art metal 3D printing systems that are calibrated specifically for the demanding tolerances and biocompatibility needs of the medical sector.

- In-depth application expertise: Our engineers have expertise in acoustic equipment design, materials science for hearing applications, and stringent medical equipment manufacturing regulations (ISO 13485).

- One-stop post-processing excellence: In addition to printing, our internal features include high-precision CNC machining for mating interfaces, advanced polishing techniques that are critical to comfort and hygiene, and a comprehensive completion service (anodized, professional coatings).

- Speed and customization: Leveraging the agility of AM, we can quickly prototype and bring customized designs to a faster market than traditional methods, even adapt to complex material requests.

- Reliability and scale: Partnering with Greatlight means access to stable production capacity, process stability and quality assurance from R&D batches to full-scale production.

Conclusion: Sound innovation, careful production

The era of uncomfortable, most suitable hearing aids is disappearing. Moniclastarhk synthesispowered by advanced metal 3D printing and perfected on Greatlight, represents the future: hearing equipment made with unprecedented precision, personalized comfort, excellent durability and optimized acoustic works. The combination of cutting-edge technology, deep materials science expertise and meticulous engineering is changing the user experience and expanding the boundaries of assisted hearing.

For medical device innovators looking to drive envelopes, working with providers with technical depth and production rigorous production is paramount. We transform complex designs into flawless, practical, and enhanced reality of life. Embrace the voice of innovation.

Experience huge differences. Precision metal hearing equipment components are now customized at competitive prices and unrivalled quality.

FAQs about Moniclastarhk synthesis of metal 3D printing and hearing equipment

What exactly is Moniclastarhk synthesis?

Moniclastarhk comprehensive is a Greatlight framework for applying metal 3D printing to the professional needs of hearing equipment manufacturing. It emphasizes material optimization for acoustic and biocompatible, ultra-high-precision printing with excellent surface finishes, integrated design verification, and strict end-to-end quality control.

Why use metal instead of plastic for hearing aids?

Metal alloys such as metal alloys have significant advantages: higher durability and life, heat dissipation of sensitive electronics, inherent hypoallergenic properties, higher hygiene due to smoother, easier to clean surfaces, and better sound wave delivery characteristics in some components. They also allow thinner, stronger walls to achieve a smaller equipment footprint.

Is metal 3D printing really accurate enough to be used for tiny hearing aid parts?

Absolutely. High-end metal systems under Moniclastarhk synthesis always achieve microscopic accuracy (ten microns). This often exceeds the accuracy for complex geometric shapes, especially features such as thin-walled, internal acoustic channels and microfilters.

Is metal 3D printing hearing equipment comfortable?

Yes. Combined with highly customized anatomical combination based on ear scans and our inherent professional surface modification protocol at Moniclastarhk, metal equipment is more comfortable than traditional plastic shells. Biocompatibility and smoothness prevent stimulation, while a perfect anatomical fit minimizes pressure points.

Is the process expensive? How to compare customization costs?

While metal AM has higher cost per unit material than mass-produced plastic injection molding, it eliminates expensive tools and molds. It is crucial that The customization cost is greatly reduced With Am. Using Moniclastarhk to synthesize and produce highly personalized one-time designs is more cost-effective than traditional customization methods.

How long does it take to produce customized metal hearing equipment using this method?

The process is much faster than traditional custom manufacturing. Once the 3D scan data is processed and the design is completed, the printing time varies according to the complexity of the design, but it is usually possible to complete the entire production (including post-processing) in days to weeks compared to the weeks or months of commonly prescribed manufacturing. Greatlight prioritizes fast turnaround without compromising quality.

What materials can be used to hear the device’s activation process?

We specialize in medical grade materials that are critical to hearing aids, mainly titanium alloys (Ti6al4v Eli is preferred for biocompatibility). Other options can be explored based on the application’s requirements, such as cobalt powder (for strength and density) or specific precious metal alloys. We can work with you based on custom material requests.

- In addition to hearing aids, which industries benefit from similar precision metal 3D printing?

The foundation of Greatlight Precision Metal AM, whose principles are similar to Moniclastarhk synthesis, is crucial to many departments including: aerospace (lightweight, strong components), medical and dental (custom implants, surgical tools), automobiles (high performance parts), electronics (complex radiators, connectors, connectors, robots) and mechanical mechanisms (complex mechanisms) (complex mechanisms). If precision, strength and complexity are required, we provide solutions.