Precision engineering for custom CNC machining: revolutionizing the production process

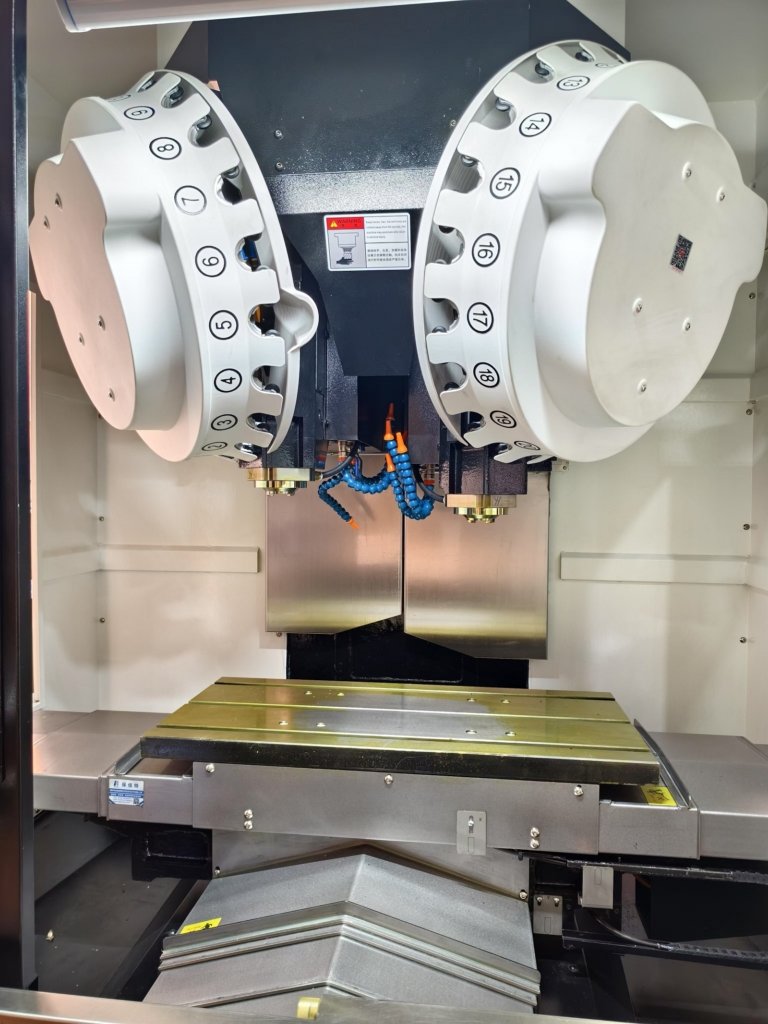

In today’s fast-paced manufacturing environment, precision engineering and custom CNC machining are changing how companies produce. As a leading provider of five-axis CNC machining services, Great Light has ushered in a new era of Precision engineering, enabling enterprises to produce complex parts quickly, accurately, accurately and cost-effectively. In this article, we will dig into the world of precision engineering with customized CNC machining and explore the benefits of working with leading companies like Great Light.

The rise of customized CNC machining

Custom CNC machining revolutionizes the production process by allowing companies to produce complex custom parts with unparalleled precision. This advanced manufacturing technology uses computer-controlled machines to accurately cut, drill and shape metals and other materials with the highest level of accuracy. With the ability to produce complex parts designs, small batch production and mass production, customized CNC machining provides the company with new opportunities to innovate and compete in the global market.

Benefits of custom CNC machining

- Improve accuracy: Custom CNC machining enables the production of parts with unprecedented accuracy, reducing the risk of errors and improving overall product quality.

- Customized solutions: With the ability to produce complex and customized parts, the company can now provide customers with tailored solutions that will have a competitive advantage in the market.

- Effective production: Customized CNC machining reduces production time by 50%, allowing the company to respond quickly to emerging market trends and customer needs.

- Save costs: Customized CNC processing can help companies save time and money by reducing manual labor and minimizing the need for rework.

Great Light’s expertise in 5-axis CNC machining

From important situations, we understand the importance of precision engineering and invest in advanced five-axis CNC machining equipment and production technology. Our team of experts has many years of experience in precision engineering and works with a variety of industries including aerospace, automotive, medical and more. With great lighting, you can trust that precision parts will be manufactured to the highest standards, ensuring precise tolerances and meeting your specific requirements.

in conclusion

Customized CNC machining has transformed the production process, allowing companies to produce complex custom parts with unprecedented accuracy and accuracy. From a long standpoint, we are committed to providing our customers with first-class precision engineering solutions tailored to their specific needs. If you are looking for a trusted partner to help you completely transform your production process, please contact us today.

FAQ

Q: What is customized CNC machining?

A: Customized CNC machining is an accurate engineering technology that uses computer-controlled machines to produce complex parts with high accuracy and precision.

Q: What are the benefits of custom CNC machining?

A: Customized CNC machining provides improved accuracy, customized solutions, effective production and cost savings.

Q: What types of industries does excellent light serve?

A: Great Light has expertise in providing services to various industries including aerospace, automotive, medical, etc.

Q: How do I know if my project requires customized CNC machining?

A: If you need to produce complex custom parts with high precision and precision, custom CNC machining may be the right solution for your project.