Precise Art and Science: How to Upgrade Mobile Phone Case with Five-Axis CNC Processing Technology

In a world of competitive smartphones, aesthetics, durability and user experience are crucial. Consumers need equipment that feels premium, looks sophisticated and endures everyday use. This relentless pursuit requires manufacturing capabilities to break through boundaries, especially the outermost layer – the phone case or chassis. Enter Accurate CNC machiningspecifically Five-axis CNC(Computer Numerical Control), this technology converts high-quality raw materials into stylish, reliable structural components that define today’s high-end equipment. From a clear perspective, we specifically leverage this advanced capability to transform complex design aspirations into tangible precise metal reality.

Beyond the surface: The core attraction of CNC phone shells

Why choose CNC machining for phone case? The answer lies in its unparalleled delivery capability:

- Final accuracy and tight tolerances: Telephone components require microscopic accuracy. The gap, misalignment and uneven surfaces do not begin. CNC machining, especially 5 axes, enables tolerances measured in microns, ensuring seamless fit to displays displays, buttons, cameras and other integrated components.

- Superior material versatility: From lightweight, durable aluminum alloys such as 6061 and 7075 to scratch-resistant stainless steel, thermal management of high conduction copper, and even exotic aerospace-grade titanium, CNC machining can handle all the treatments. This flexibility allows manufacturers to choose the perfect material for their design goals – whether it is lightweight, strength, signal transparency or a premium feel.

- Unparalleled structural integrity: Unlike stamped or cast components, CNC machining begins with solid blocks of material (billet). The processing process can eliminate excess material without changing the internal grain structure, resulting in increased mechanical strength, rigidity and resistance to deformation.

- Exquisite finishes and details: Acoustic performance of precisely milled, perfectly chamfered edges, comfortable grip, custom texture engraved on the surface and seamless radio window integrals – 5-axis CNC machining brings intricate design details to life with impeccable consistency. Complex curves and organic shapes (impossible fewer axes) are performed perfectly.

- Rapid prototyping and scalability: CNC machining ranges from low volume prototype production to mass production. Design iterations can be quickly translated into working samples for testing and verification. Once completed, the same process will effectively scale, thus maintaining the same quality in thousands or millions of units.

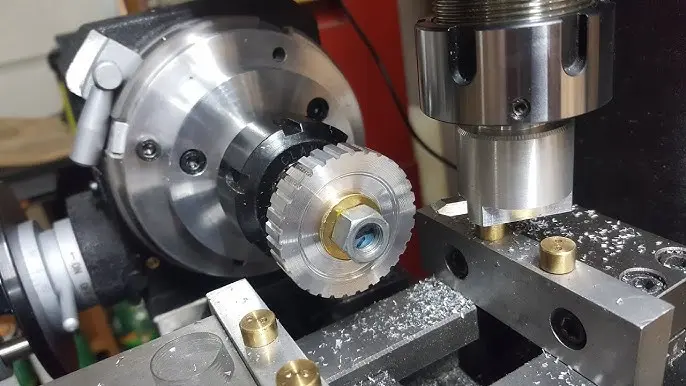

Why Five Axis is the game changer for smartphone chassis:

Traditional three-axis machining (motion in X, Y, Z) has limitations when dealing with complex geometry. Four axis increases rotation on one horizontal axis. Five-axis CNC machining significantly raises the standard:

- Five-axis control is performed simultaneously: The cutting tool and workpiece can move dynamically along five axes simultaneously. This allows access to any angle of the part without multiple settings.

- 360° machining in a single fixture: Complex mobile phone chassis designs can be processed from all aspects in a single setup. This eliminates errors associated with repositioning parts and greatly reduces processing time.

- Complex contours and deep cavity: Accessed with excellent tools, the phone’s ergonomic curve or deep, narrow port openings are perfectly engraved.

- Enhanced finish and geometric accuracy: Enable continuous tool paths with multi-axis motion ensure smoother on the contoured surface and eliminates common step markings in 3-axis machining. Complex antenna lines and complex camera geometry are very easy.

- Shorter tools and higher accuracy: Processing from the optimal angle allows for shorter, more rigid cutting tools, which reduces deflection, improves accuracy, finer details, and extends tool life.

- Reduce production lead time: Combining multiple operations (roughing, finishing, drilling, digging) into fewer settings can significantly speed up the entire production cycle.

Huge light advantages:

From a very obvious perspective, we are more than just operators. We are problem-solving and specializing in precision metal manufacturing. We use advanced five-axis CNC machining technology and deep expertise to target unique challenges in phone case production:

- Engineering Consulting: We work closely from the early stages – advising on optimal material selection (balanced RF performance, strength, weight), manufacturability (manufacturability design-DFM) to ensure cost-effectiveness and tolerance are feasible.

- Advanced Fixed: We design and build professional fixtures optimized for maximum stiffness and access in complex five-axis machining sequences to ensure accuracy and protect delicate features.

- Thermal management expertise: Processing high-strength aluminum alloys or titanium requires careful control of cutting forces and heat generation to prevent handheld and surface stress, which is crucial for flatness and cosmetic quality. Our process engineers carefully optimize cutting parameters.

- One-stop integration completion: Precision machining is just the first step. Great light seamlessly delivers comprehensive post-processingis crucial to the final look:

- Burr and surface treatment: Advanced technology (e.g., thermal burrs, centrifuge finishes) ensures that all edges are imperfect and have no micropores.

- Precise polishing: Get high gloss mirror or specific matte satin that is required by quality brands.

- Anodized (aluminum): Provides durable, corrosion-resistant color finishes and enhanced surface hardness.

- PVD coating (stainless steel/titanium/alloy): Apply ultra-thin, wear-resistant coatings such as titanium nitrate (TIN) or unique colors for aesthetics and protection.

- Laser engraving and texture: Add a logo, serial number, or specific tactile surface texture.

- Passivation: Enhance the corrosion resistance of stainless steel.

- Strict quality control: Each stage is based on a strict quality protocol. We use advanced metrology equipment (CMM-coordinate measuring machines, vision systems, surface roughness testers) to verify dimensions, tolerances and finishes for the required specifications.

Engineering Meets Art: The journey of mobile phone case production is very bright:

- Design and DFM collaborate: Work with clients to finalize design, materials and critical tolerances.

- Billet preparation: Choose the highest-level metal stock, precisely to size.

- Five-axis CNC strategic processing: Multi-stage operation uses the best tool paths and professional tools to deploy rough, semi-fix and sort passes. Key structural features, ports, antenna lines and complex curves are processed.

- Thorough cleaning: Remove all processing residues (SWARF, coolant).

- Auxiliary processing (if required): Any necessary drilling, excavation or special milling after primary body machining.

- Burrs and surface smoothing: Carefully eliminate any sharp edges or defects.

- Precise completion: Apply the selected surface treatment (anodizing, polishing, PVD, etc.) and perform the final surface cleaning and packaging ready for assembly.

Conclusion: Precise craftsmanship of the palm

On the harsh stage of smartphone manufacturing, shells are more than just a situation. It is the identity, main interface and structural kernel of the device. Implementing a perfect blend of form, functionality, durability and visual appeal only requires the pinnacle of manufacturing technology: Five-axis accurate CNC machining. This process provides microscopic tolerances, complex geometry, excellent materials and perfect finishes to define flagship equipment.

Great lighting stands at the forefront of this advanced manufacturing frontier. With our cutting-edge five-axis CNC capabilities, deep metallurgy expertise, integrated one-stop solution and a strong commitment to quality, we transform complex designs into precisely made high-performance mobile phone chassis. We are not only manufacturers, but also problem-solving engineers, committed to bringing outstanding products to the market.

Ready to enhance your next smartphone design with a precisely designed CNC phone case?

Excellent light is your ideal partner for complex CNC solutions, rapid prototyping and quantity generation. Customize your precision parts now!

FAQ: Precision CNC machining of mobile phone case

Q1: Why is CNC machining better than die-casting or stamping for advanced phone case?

A: CNC machining provides precision and stricter tolerances. It produces parts with high structural integrity (porosity inherent in casting) and handles more complex, complex geometries that cannot be achieved by stamping. Surface finish quality and consistency are also significantly higher.

Q2: What CNCs are usually processed to the material of the mobile phone case?

A: The most common are high-strength aluminum alloys (6000 and 7000 series) to balance lightness, strength, cost and processability. Stainless steel (especially 304, 316) is used to increase durability/RF characteristics, titanium (Gr 5, GR 23) is used for advanced weight/strength and occasionally heat-managed brass/copper alloys.

Q3: Can the wall be processed much more on the CNC phone case?

A: This depends to a lot on the materials and processing strategy. Reliable wall realization with modern five-axis technology and advanced tools 0.3mm -0.5mm It is common in aluminum for high-end equipment. Achieving thinner walls requires excellent tools, fixing and process control to prevent vibration or deflection.

Q4: How long does it usually take for CNC to process a mobile phone case?

Answer: The actual machining time of each part varies greatly due to complexity, materials and fixtures. However, measurements are usually performed on a computer in units of zero pieces. The five-axis greatly reduced Comprehensive Compared with 3-axis machining, the production time set by merging. A complete production schedule (including completion) is project-specific.

Q5: Is Precision CNC processing a cost-effective way to produce telephones?

one: Yes, especially for high-precision and advanced devices. While the cost per unit of processing is higher than the large amount of mass production technologies such as stamps or castings, its advantages (quality, design freedom, strength, faster time to market for complex designs, faster cost of iterative tools) make it very cost-effective for high-end smartphones. Five-axis also improves cost-effectiveness by reducing labor and setting up costs.

Question 6: How does Greatlight handle antenna integration in metal bodies?

Answer: Metal block RF signal. We work closely on DFM to incorporate precise machining slots or wires filled with non-conductive materials (plastics, ceramics) to form the necessary antenna windows. Our five-axis accuracy ensures that these features are milled with the precise tolerances required for optimal wireless performance (Wi-Fi, Bluetooth, cellular, NFC, GPS).

Question 7: Can Greatlight handle prototypes and mass production?

one: Absolutely. Our advanced five-axis capabilities are ideal for rapid high-fidelity design complex designs. The same technology, coupled with optimized programming and production workflows, is scaled seamlessly to support large-scale manufacturing operations, ensuring consistency from the first post to the final shipment.

Question 8: Why choose Greatlight specifically for five-axis CNC phone case?

A: In addition to advanced equipment, we also provide deep Domain expertise Specific to precise consumer electronics, complex forms and challenging materials. We’re fully integrated One-stop service (Machining, finishing, inspection) Simplify your supply chain and ensure overall quality control. We focus on A partner who solves the problemprovides manufacturing scale solutions supported by good quality systems.