Accurate single-use CNC machining: a portal to complex, high-quality prototypes and end-use parts

The need for speed, accuracy and flexibility is crucial in the fast-paced world of manufacturing and product development. Whether you are an entrepreneurial engineer Accurate single-use CNC machining is an indispensable solution. For projects that require the highest accuracy and complexity, Five-axis CNC machining Provided by experts Great Not only is it an option, but it is the best way to succeed.

What is disposable CNC machining?

Single-use CNC machining refers to the production of a single custom design part using computer numerical control (CNC) technology. Unlike mass production, the focus of one-time machining is to make unique components or low batches (usually prototypes, tools, tools or highly professional parts) in the case of making thousands of the same items. The process begins with a digital 3D model (CAD file) that will accurately guide precise cutting, milling, turning or drill bit material to the exact specifications.

The core value lies in its Customization and precision. Each section can be individually made with its unique blueprint to ensure it is perfectly suited to its intended application, regardless of complexity.

Input the power of five-axis machining

Traditional CNC machining usually involves three-axis systems (X, Y, Z – basically moving left/right, forward/back/up/up). This limits possible part orientation without manual intervention, often requiring multiple settings for complex geometry.

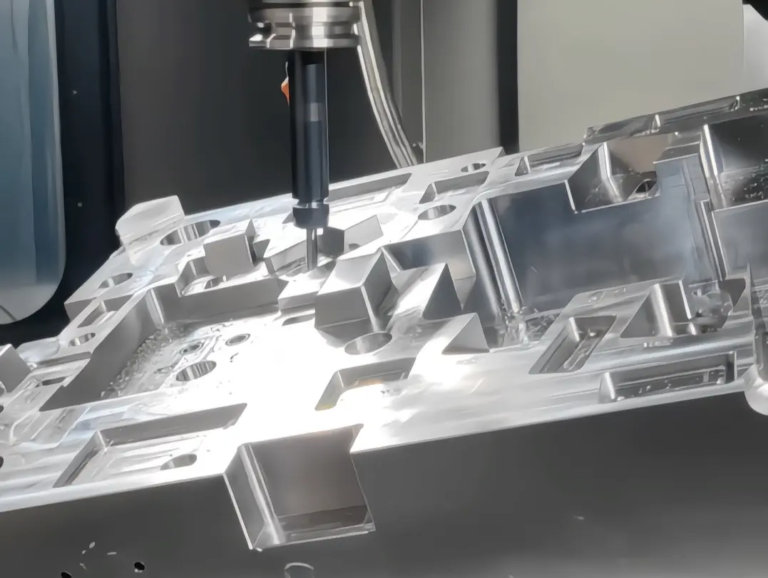

Five-axis CNC machining can enhance this capability exponentially. As the name implies, it provides five different axes of motion at the same time:

- Linear axis (X, Y, Z): Used for standard sports.

- Rotating axis (A&C): Allows cutting tools and/or workpieces to rotate and tilt sharply.

This simultaneous multi-axis motion provides a game-changing advantage for the one-time section:

- Complex geometric shapes make it simple: Create profiles, deep cavity, undercuts, composite angles and organic shapes that are impossible or too expensive to use with a 3-axis machine – all in a single setup.

- Unrivaled accuracy and surface surface: Fewer settings greatly reduce the risk of introducing errors through manual repositioning. Continuous, optimal tool paths improve dimensional accuracy and surface quality.

- Reduce setup time and cost: Complex parts can be processed in one fixture, eliminating the time and costs associated with multiple settings and fixtures, thus making production more efficient.

- Shorter delivery time: Simplify the setup and machining process directly into faster delivery of your critical custom parts.

- Effective tools to use: Tools can maintain the optimal cutting angle more stably, thereby extending tool life and improving machining efficiency.

GRESTHERMENG: Your partner for accurate one-time manufacturing

This is Great shine. As a professional manufacturer Advanced five-axis CNC machiningWe have the expertise and technology to use metal materials to convert the most demanding one-time requirements into tangible high-precision components.

Why do you need to work with your one-time CNC?

- Advanced five-axis expertise: We not only operate five-axis machines; we master them. Our investment in state-of-the-art equipment, coupled with extensive engineering knowledge, allows us to solve the most challenging parts with confidence and precise ways.

- Comprehensive material palette: Whether it is aerospace grade aluminum, titanium, stainless steel, brass or various engineering plastics, Greglight can handle a large number of metal materials. We select the best materials and machining strategies for your part functionality and durability.

- True one-stop features: In addition to machining, we also simplify your workflow by providing an integrated suite of suites. Post-processing and completion of services. From expert burrs and precision surface grinding (including flatness, parallelism, verticality standards, etc. 0.005/0.01mm) to polishing, various plating, anodizing, sandblasting, laser etching and packaging – we handle it under one roof. This ensures consistency in quality and saves you a lot of time managing multiple vendors.

- Quick custom solution: Time is crucial. We understand the urgency of one-time projects. Our optimized process and skilled team aim to Quickly provide customized precision partssubject to a pressing deadline without damaging quality.

- Precise design: Every step from initial design consultation (if required) to final inspection is guided by commitment to the meeting Strict tolerances It is crucial for functional prototypes and mission-critical components.

- Direct cost advantage: Combined with state-of-the-art equipment, effective single-set machining (especially using 5 axes) and direct manufacturing functions, it can be well provided. High-quality disposable parts, best price.

When is five-axis disposable CNC machining essential?

This service is ideal for a variety of situations requiring unparalleled precision and geometric freedom:

- prototype: Create functional, high-fidelity prototypes to accurately represent the form, fit and function of the final design.

- Fixtures, fixtures and tools: Manufacturing custom tools and holding equipment that is critical to other manufacturing processes.

- Complex end-use parts: Production of small volume or single-piece components for industries such as aerospace, medical equipment, automobiles (especially motorsports), robotics, defense and industrial automation, where complexity and accuracy are impossible.

- Replacement parts: Made outdated, worn or customized components for legacy machinery that cannot be provided.

- Design Verification: Test complex design features before committing to mass production.

in conclusion

Navigating the complexity of single-use precision parts manufacturing requires state-of-the-art technology, deep material knowledge and proficient execution. Five-axis CNC machining Represents the pinnacle of the ability to obtain complex geometry and excellent quality in a single or low batch. GreatIt is strategically a trusted partner for your dedicated focus on advanced five-axis technology, a wide range of material levels and comprehensive post-processing solutions. We transform complex one-time challenges into effective and cost-effective tangible, high-precision reality that empowers you to innovate and solve critical manufacturing problems. Don’t satisfy your critical components of compromise – Select precision, choose complexity mastery, and choose Greatlight for your custom precision CNC machining needs.

Customize your precision parts now at the best prices! [Contact GreatLight Today – Consider adding a Call to Action here, e.g., "Request a Quote" link]

FAQ (FAQ)

Q1: How quickly can Greatlight provide accurate single-use CNC machining parts?

Answer: Greatlight specializes in rapid custom processing. The advance time varies greatly depending on the complexity of the part, the selected materials and the required finishing process. However, leveraging our advanced five-axis capabilities often eliminates multiple settings, allowing us to manufacture composite parts faster than traditional methods. We provide specific estimated delivery times based on your project requirements, prioritizing fast delivery without sacrificing quality.

Q2: Can Greatlight really process any metal for disposable parts?

A: We cooperate extensively with Metal materialincluding common alloys such as aluminum (e.g., 6061, 7075), stainless steel (e.g., 303, 304, 316), steel, brass and copper, as well as more challenging materials such as titanium (grade 2, grade 5, grade 5), Inconel and other foreign alloys. When we cover "Most materials," Feasibility always depends on the specific grade, the complexity of geometry and the required tolerances. Please consult our engineering team for detailed information about your specific material needs.

Q3: What file format do I need to provide to provide a one-time CNC quotation?

A: Ideally, a 3D CAD model is provided in common formats such as step (.STP, .STEP), SOLIDWORKS (.SLDPRT), PARASOLID (.X_T, .X_B) or IGES (.igs). The accompanying 2D drawings (.pdf, .dwg, .dxf) have key dimensions, tolerances, surface surfaces and material specifications that are very valuable for accurate quotes and manufacturing.

Question 4: Why is five-axis CNC machining more expensive than three-axis?

A: The 3-axis process is often more cost-effective for geometric parts that are easily machined in a setup on a 3-axis machine. However, Five axis becomes a superior value proposition when complexity increases. Although the machine cost/hour may be higher, it eliminates multiple settings and complex fixation. This greatly reduces labor time, and will program overhead if the part requires complex setup, potential errors in requantity, and overall delivery time. Therefore, for complex parts, five-axis machining is often More Overall effective and cost-competitive.

Q5: What completion options can be used for my disposable parts?

A: Greglight provides a comprehensive range Back face of mobile phone. This includes:

- Surface finish: Smooth tolerance machining (e.g., achieving flatness, parallelism, reduced perpendicularity to 0.005/0.01mm), precise burrs, super polishing (optical effects).

- Aesthetic/protective finish: Anodized (transparent, black, color), electroplating (nickel, chromium, zinc), powder coating, passivation.

- Texture/clear debris: Sandblasting (bead explosion), sour pickling, etching.

- mark: Laser etching/engraving.

- Clean and pack.

We recommend the best finish based on the material, application of your part, and the required aesthetic or functional properties (such as corrosiveness).

Question 6: How does Greatlight ensure competitive prices for individual parts?

A: Our attention Process efficiency It’s the key. By leveraging advanced five-axis machining to minimize setup, optimize tool paths, leverage internal decoration, control material procurement and maintain direct communication to avoid errors and rework, we can simplify production. This operational efficiency, coupled with the economies of scale of our established infrastructure, allows us to provide surprisingly competitive Even for single, highly accurate pricing of components Compared to a less professional store. We encourage you to compare our quotes!