2023Year5moon5The same day, Mohou.com learned that the manufacturer of automated post-processing systemsPost-processing technologiesAnnouncement of the launch of a new rinsing solutionAUX-400-RINSEused to replace3DIsopropyl Alcohol in Print Manufacturing Resin Removal Workflow (API) rinsing step. The manufacturer of the automated post-processing system has stated that:AUX-400-RINSEAble to effectively clean powder and supporting materials remaining on resin parts and reduce liquid waste and processing time during washing process.

△Post-processing technologiesofAUX-400-RINSEasAPIAlternatives to the rinsing step to optimize3DPrinting process

Safer and environmentally friendly reprocessing solutions

This solution is designed for resin applications, giving customers the freedom to useAPIPost-processing workflow, including final rinsing and drying steps.

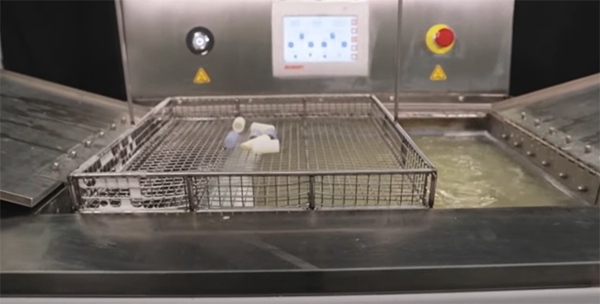

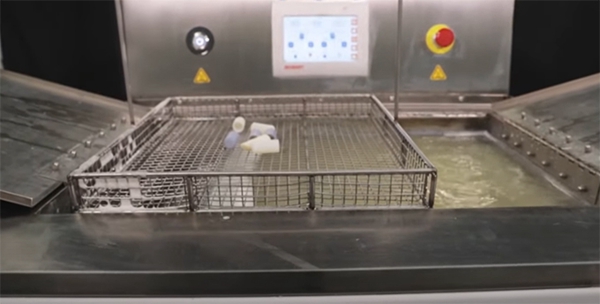

△In3DIn print manufacturing, parts coming out of the printer require additional post-processing steps.

according toPost-processingargument,AUX-400-RINSEThe flash point temperature is higher, approximatelyAPItwice as much, making it less dangerous and reducing the risk of employee injury or property damage. In addition, it has less evaporation losses, a longer lifespan and is more cost-effective to use.90% green chemicals, also improves environmental impact.

Post-processingDirector of ChemistryMatthew Noblesaid: “We are delighted to launchAUX-400-RINSEasAPIImprovements and safer alternatives to flushing steps to increase customer safety and efficiency. We are always committed to providing better solutions to our customers, andAUX-400-RINSEis yet another example of this commitment. “

△Post-processing process3DPrinting Parts Schematic

asAPISafer Alternatives to Flushing

exist3DDuring the printing and manufacturing process, in order to remove uncured resin and prepare for the next processing step (such as dyeing, drying, etc.), it is usually necessary to use resin isopropyl alcohol for rinsing, which is one of the common methods. -processing steps. However, due to the dangers and environmental impact of isopropyl alcohol,Post-processingThis new flushing solution was launched as a safer solutionAPIAlternatives to rinsing. This innovation can meet the market expansion needs in terms of technology and demand.

It is reported that,3DPrinting, injection molding and foundry service providerQuick PartsYesAUX-400-RINSEone of the first users.

Quick partsDirector of OperationsBarbe TracyAs a leader in on-demand manufacturing services, they are committed to cutting-edge additive processes, technologies and materials. they were delighted to participate Post-processing newAUX-400-RINSEmaterials, and after numerous comparisons between its overall performance andAPIAfter rinsing, they can be used with confidencePost-processing DEMI 4000In the standard resin workflow, this material can effectively replaceAPIRinse the printed parts.

△Post-processingofCVSPost-processing technology

aboutPost-processing

The company is a leading provider of automated and intelligent solutions for additive manufacturing post-processing, founded in2014Headquartered in Buffalo, New York, United States, with international operations in Moulins, France. The company integrates patent-pending software, hardware and chemical technologies to provide industrial services3DAutomation provides solutions for the most common post-processing processes in printing, including support structure removal, resin and powder removal, and surface preparation.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.